A butt weld 45 degree long radius elbow is a type of pipe fitting that is used to change the direction of the flow in a piping system by 45 degrees. It is designed with a long radius, which means that the curvature of the elbow is relatively gentle, allowing for a smoother flow of fluid through the system. Butt weld 45 degree long radius elbows are made by welding two pipes or tubes together at a 45 degree angle, with the weld seam being flush with the surface of the elbow. They are commonly used in industries such as oil and gas, petrochemicals, and power generation to connect pipes and redirect the flow of fluids around obstacles or through corners.

Butt weld Fitting 45° Long Radius Elbow Specification

| Стандарти | ANSI/ASME :ASTM A403 / ASME SA403, ANSI B16.9, ASME B16.25, ASME B16.28, MSS SP-43.

ОТ : DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 IN : EN10253-1, EN10253-2 |

| График | График 5S, 10С, 20С, S10, S20, S30, STD, 40С, S40, S60, XS, 80С, S80, S100, S120, S140, S160, XXS и др. |

| Размери | Seamless 45° Long Radius Elbow Size: 1/2″~24″

АКР / Заварени / Fabricated 45° Long Radius Elbow Size: 1/2″ (15 NB) to 48″ (1200NB) |

| оценки | 304/L/H/LN, 316/L/H/LN/Ti, 321/з, 317/L/LN, 347/з, 310С/з, N08904(904Л), S31803, S32205, S32750, S32760, N02200, N02201, N04400, N06600, N06690, N06625, N06985(G3), N08028, N08800, N08810, N08811, N08825Повърхност |

| Тип | Челно заваряване (BW) / Заварени / АКР / Изфабрикувани |

| Измерение | ANSI B16.9, ANSI B16.28, MSS-SP-43 Тип A, MSS-SP-43 Тип B, |

Butt weld Fitting 45° Long Radius Elbow MATERIAL & ОЦЕНКИ

| Челно заваряване от неръждаема стомана 45 Градус Коляно с дълъг радиус | ASTM A403 WP316/316Л, ASTM A403 SA / А 774 WP-S, WP-W, WP-WX 304/304L, ASTM A182 F316L, 304Л, ОТ 1.4301, DIN1.4306, ОТ 1.4401, ОТ 1.4404 |

| Дуплекс & Супер дуплексна стоманена челна заварка 45 Градус Коляно с дълъг радиус | ASTM A 815, ASME SA 815 US NO S31803, S32205. САЩ S32750, S32950. Материал №. 1.4462 |

| Челно заваряване от въглеродна стомана 45 Градус Коляно с дълъг радиус | ASTM A234, ASME SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

| Нискотемпературна въглеродна стомана 45 Градус Коляно с дълъг радиус | ASTM A420 WPL3, A420 WPL6 |

| Челно заваряване от легирана стомана 45 Градус Коляно с дълъг радиус | ASTM / ASME A/S.A 234 Гр. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

| Челно заваряване от никелова сплав 45 Градус Коляно с дълъг радиус | ASTM B336, ASME SB336, никел 200 (US No. No2200), никел 201 (US No. N02201), Монел 400 (US No. N04400), Монел 500 (US No. N05500), Инконел 800 (US No. N08800), Инконел 825 (US No. N08825), Инконел 600 (US No. N06600), Инконел 625 (US No. N06625), Инконел 601 (US No. N06601), Hastelloy C 276 (US No. N10276), Сплав 20 (US No. N08020), Титан (степен I & II), Купро-никел 70/30, CuNi10Fe1Mn, CuNi30Mn1Fe. |

Applications of 45 ГРАДУС ДЪЛЪГ РАДИУС ЛАКЪТ

- Stainless Steel 45° Long Radius Elbow uses in Oil and Gas Pipeline

- 45° Buttweld LR Elbow uses in Chemical Industry

- Alloy Steel 45° Long Radius Elbow uses in Plumbing

- 45° Long Radius Elbow Pipe Fittings uses in Food Processing Industry

- Buttweld 45° LR Elbow uses in Structural Pipe

- ANSI B16.9 Buttweld 45° Long Radius Elbow uses in Power Plant

- 45° Long Radius Pipe Elbow uses in Paper & Pulp Industry

- 45 Deg Long Radius Bend uses in Heating

- 45 Degree Long Radius Reducing Elbow uses in Water Supply Systems

- ASME B16.9 Long Radius 45 Deg Elbow uses in General Purpose Applications

- 45° LR Elbow uses in Fabrication Industry

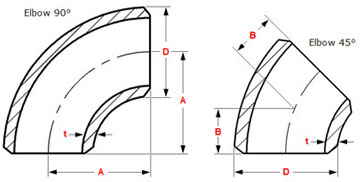

45 Deg Long Radius Elbow Размери

Челно заваряване 45 Degree Long Radius Elbow Dimension Drawing

| NPS | O.D.

д |

90 degrees

Long Radius Center-to-End А |

45 degrees

Long Radius Center-to-End B |

90 degrees

3д Center-to-End А |

45 degrees

3д Center-to-End B |

| 1/2 | 21.3 | 38 | 16 | – | – |

| 3/4 | 26.7 | 38 | 19 | 57 | 24 |

| 1 | 33.4 | 38 | 22 | 76 | 31 |

| 1 ¼ | 42.2 | 48 | 25 | 95 | 39 |

| 1 ½ | 48.3 | 57 | 29 | 114 | 47 |

| 2 | 60.3 | 76 | 35 | 152 | 63 |

| 2 ½ | 73 | 95 | 44 | 190 | 79 |

| 3 | 88.9 | 114 | 51 | 229 | 95 |

| 3 ½ | 101.6 | 133 | 57 | 267 | 111 |

| 4 | 114.3 | 152 | 64 | 305 | 127 |

| 5 | 141.3 | 190 | 79 | 381 | 157 |

| 6 | 168.3 | 229 | 95 | 457 | 189 |

| 8 | 219.1 | 305 | 127 | 610 | 252 |

| 10 | 273 | 381 | 159 | 762 | 316 |

| 12 | 323.8 | 457 | 190 | 914 | 378 |

| 14 | 355.6 | 533 | 222 | 1067 | 441 |

| 16 | 406.4 | 610 | 254 | 1219 | 505 |

| 18 | 457 | 686 | 286 | 1372 | 568 |

| 20 | 508 | 762 | 318 | 1524 | 632 |

| 22 | 559 | 838 | 343 | 1676 | 694 |

| 24 | 610 | 914 | 381 | 1829 | 757 |

| 26 | 660 | 991 | 406 | 1981 | 821 |

| 28 | 711 | 1067 | 438 | 2134 | 883 |

| 30 | 762 | 1143 | 470 | 2286 | 964 |

| 32 | 813 | 1219 | 502 | 2438 | 1010 |

| 34 | 864 | 1295 | 533 | 2591 | 1073 |

| 36 | 914 | 1372 | 565 | 2743 | 1135 |

| 38 | 965 | 1448 | 600 | 2896 | 1200 |

| 40 | 1016 | 1524 | 632 | 3048 | 1264 |

| 42 | 1067 | 1600 | 660 | 3200 | 1326 |

| 44 | 1118 | 1676 | 695 | 3353 | 1389 |

| 46 | 1168 | 1753 | 727 | 3505 | 1453 |

| 48 | 1219 | 1829 | 759 | 3658 | 1516 |

ДОПУСТИМИ ОТКЛОНЕНИЯ НА РАЗМЕРИТЕ НА 45 ГРАДУС ДЪЛЪГ РАДИУС КОЛЯНО – ASME B16.9

| DIMENSIONAL TOLERANCES – ELBOWS | |||||||

| For all fittings | Elbows 90/45 град | 180° Връщания | |||||

| Номинален размер на тръбата (NPS) | Външен Ø

в Bevel |

Вътре Ø

в края |

Дебелина на стената

t / t1 |

Center to End Dim. A-B-C-M | Център до Център Дим.

О |

Обратно към Face Dim.

К |

Подравнете- мент на Краищата

U |

| 1/2 а 2 1/2 | 1 | 0,8 | не | 2 | 7 | 7 | 1 |

| 3 а 3 1/2 | 1 | 1,6 | по-малко | 2 | 7 | 7 | 1 |

| 4 | +2 -1 | 1,6 | отколкото | 2 | 7 | 7 | 1 |

| 5 а 6 | +3 -1 | 1,6 | 87,50% | 2 | 7 | 7 | 1 |

| 8 | 2 | 1,6 | на номинална | 2 | 7 | 7 | 1 |

| 10 | +4 -3 | 3,2 | tickness | 2 | 7 | 7 | 2 |

| 12 а 18 | +4 -3 | 3,2 | 3 | 10 | 7 | 2 | |

| 20 а 24 | +6 -5 | 4,8 | 3 | 10 | 7 | 2 | |

| 26 а 30 | +7 -5 | 4,8 | 3 | ….. | ….. | ….. | |

| 32 а 48 | +7 -5 | 4,8 | 5 | ….. | ….. | ….. | |

ANGULARITY TOLERANCES OF 45 ГРАДУС ДЪЛЪГ РАДИУС ЛАКЪТ

| Angularity Tolerances | ||

| ND | Макс извън ъгъл | Макс извън самолета |

| Q | П | |

| 1/2 а 4 | 1 | 2 |

| 5 а 8 | 2 | 4 |

| 10 а 12 | 3 | 5 |

| 14 а 16 | 3 | 7 |

| 18 а 24 | 4 | 10 |

| 26 а 30 | 5 | 10 |

| 32 а 42 | 5 | 13 |

| 44 а 48 | 5 | 20 |

НАЛИЧНИ ВИДОВЕ НА 45 ГРАДУС ДЪЛЪГ РАДИУС ЛАКЪТ

| Buttweld 45° Long Radius Elbow | Duplex Steel Buttweld 45° Long Radius Elbow |

| ASME B16.9 Butt weld 45° Long Radius Elbow | High Nickel Alloy 45° Long Radius Elbow |

| Stainless Steel 45° Long Radius Elbow | SS 45° Long Radius Elbow |

| High Quality 45° Long Radius Elbow | Seamless Butt weld 45° Long Radius Elbow |

| Welded Butt weld 45° Long Radius Elbowr | ASME B16.28 Buttweld 45° Long Radius Elbow |

| Carbon Steel 45° Long Radius Elbow | ANSI B16.9 Buttweld 45° Long Radius Elbow |

| Titanium Buttweld 45° Long Radius Elbow | Inconel Butt weld 45° Long Radius Elbow |

| ASTM A403 Stainless Steel 45° Long Radius Elbow | Butt Weld B16.9 45° Long Radius Elbow |

| Super Duplex Steel Buttweld 45° Long Radius Elbow | Copper Nickel 45° Long Radius Elbow |

| Steel 45° Long Radius Elbow | Hastelloy 45° Коляно с дълъг радиус |

WEIGHT OF 45 Deg Long Radius Elbow

Buttweld Elbow Тегло in LBS and KG

| Type-> | SCHEDULE STD | SCHEDULE XS |

| NPS | LBS | KG | LBS | KG |

| 1/2 | 0.09 | 0.04 | 0.19 | 0.09 |

| 3/4 | 0.09 | 0.04 | 0.19 | 0.09 |

| 1 | 0.25 | 0.11 | 0.31 | 0.14 |

| 1 ¼ | 0.38 | 0.17 | 0.5 | 0.23 |

| 1 ½ | 0.4 | 0.18 | 0.69 | 0.31 |

| 2 | 0.81 | 0.37 | 1.19 | 0.54 |

| 2 ½ | 1.75 | 0.79 | 2.13 | 0.97 |

| 3 | 2.63 | 1.19 | 3.5 | 1.59 |

| 3 ½ | 3.5 | 1.59 | 4.5 | 2.04 |

| 4 | 4.5 | 2.04 | 6.1 | 2.77 |

| 5 | 7.5 | 3.4 | 10.7 | 4.85 |

| 6 | 12 | 5.44 | 17.5 | 7.94 |

| 8 | 23 | 10.43 | 35 | 15.88 |

| 10 | 43 | 19.5 | 53 | 24.04 |

| 12 | 62 | 28.12 | 84 | 38.1 |

| 14 | 80 | 36.29 | 100 | 45.36 |

| 16 | 100 | 45.36 | 135 | 61.23 |

| 18 | 126 | 57.15 | 167 | 75.75 |

| 20 | 160 | 72.57 | 206 | 93.44 |

| 22 | 197 | 89.36 | 260 | 117.93 |

| 24 | 238 | 107.95 | 300 | 136.08 |

| 26 | 275 | 124.74 | 365 | 165.56 |

| 30 | 367 | 166.47 | 488 | 221.35 |

| 36 | 531 | 240.86 | 706 | 320.24 |

45 Degree Elbow Cutting Formula

- R1 = elbow radius marking 1

- R2 = elbow radius marking 2

- R3 = elbow radius marking 3

EC = Elbow Center

OD = Outside Daimeter

R2 = Both Side Radius Marking

45 Degree Elbow Take Off Formula

(R1) – tan x 1 х (EC – 1/2 ОТ) x Deg = answar

(R2) – tan x 1 x EC … x Deg = answar

(R3) – tan x 1 (EC + 1/2 ОТ) x deg = answar

Доставчик на тръби от неръждаема стомана Wenzhou Kaixin Китай

Доставчик на тръби от неръждаема стомана Wenzhou Kaixin Китай