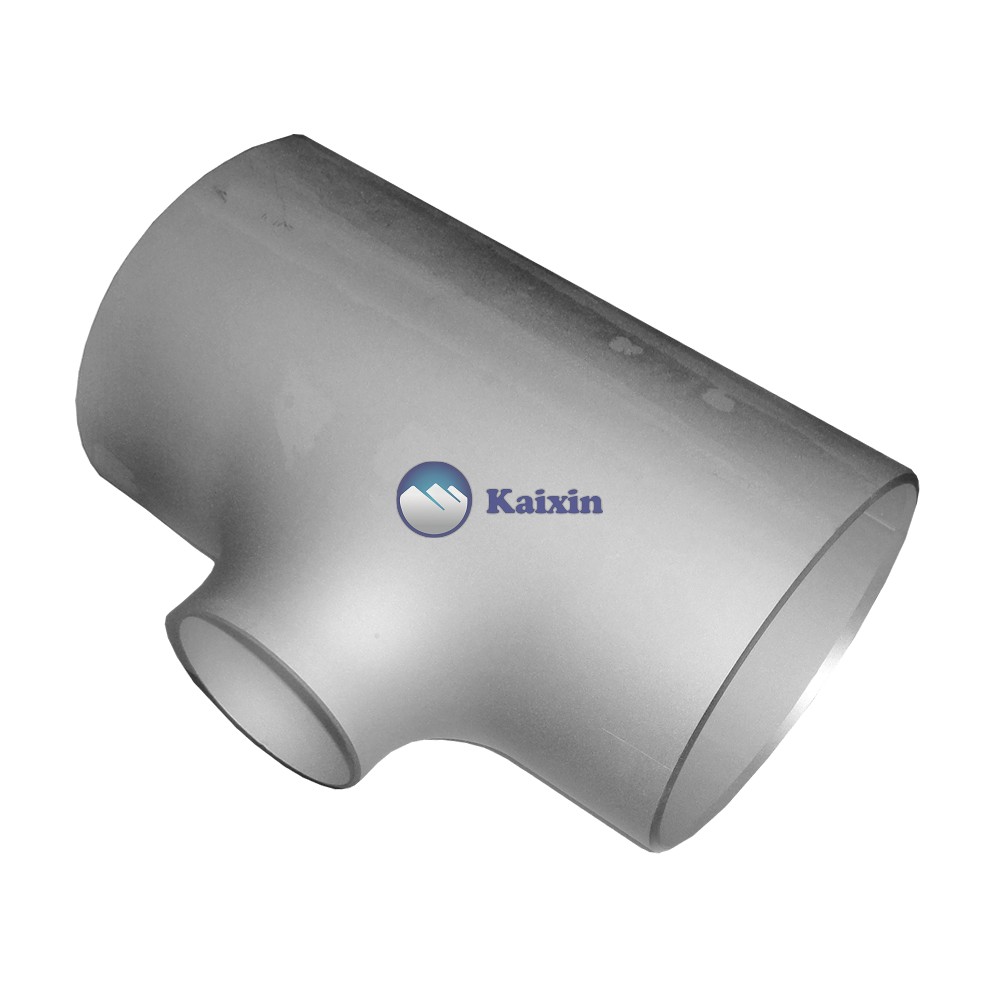

A StainlessSteelButtWeldReducingTee is a type of pipe fitting used in industrial applications to connect three pipes of different sizes. This tee fitting has a tapered outlet that is smaller in diameter than the main supply line, allowing for flow rate adjustment and distribution of fluids to multiple directions. Made of high-quality stainless steel material, this fitting exhibits excellent corrosion resistance, durability, and strength, making it ideal for use in harsh, corrosive environments such as chemical and petrochemical plants, oil and gas refineries, Generació d'energia, and water treatment. The butt-weld design ensures a secure and tight fit, preventing leakage and ensuring maximum efficiency.

BUTTWELD REDUCING TEE SPECIFICATIONS

| Mides | Seamless Pipe Reducing Tee ( 1/2″~24″), ACRE / Soldat / Fabricated Pipe Reducing Tee (1/2″~48″) |

| Normes | ANSI/ASME :ASTM A403 / ASME SA403, ANSI B16.9, ASME B16.25, ASME B16.28, MSS SP-43.

DE : DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 EN : EN10253-1, EN10253-2 |

| Dimensions | ASME/ANSI B16.9, MSS-SP-43 tipus A, MSS-SP-43 tipus B, HE B2312, JIS B2313, ASME B16.28 |

| Gruix | Horari 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS i etc. |

| Radi de flexió | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom Pipe Fittings |

| Des de | Unequal Tee, Reducing Tee, Pipe Tee, Butt weld Unequal Tee. |

| Graus&Materials | 304/L/H/LN, 316/L/H/LN/Ti, 321/H, 317/L/LN, 347/H, 310S/H, N08904(904L), S31803, S32205, S32750, S32760, N02200, N02201, N04400, N06600, N06690, N06625, N06985(G3), N08028, N08800, N08810, N08811, N08825 Superfície,Monel, Níquel, Inconel, Hasalloy, Titani, Tàntal, Acer inoxidable, Acer d'aliatge, Acer carboni, Cupro-níquel 90/10 & 70/30, Acer inoxidable ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, DE 1.4301, DIN1.4306, DE 1.4401, DE 1.4404 |

| Tipus | Soldadura a tope (BW) / Sense costures / Soldat / ACRE / Fabricat |

| Coating / Tractament superficial | Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

Buttweld Reducing Tee Materials and Grades

| tainless Steel Unequal / Reducing Tee | ASTM A403 WP316/316L, ASTM A403 SA / A 774 WP-S, WP-W, WP-WX 304/304L, ASTM A182 F316L, 304L, DE 1.4301, DIN1.4306, DE 1.4401, DE 1.4404 |

| Dúplex & Super Duplex Steel Unequal / Reducing Tee | ASTM A 815, ASME SA 815 UNS NO S31803, S32205. EUA S32750, S32950. Material núm. 1.4462 |

| Carbon Steel Unequal / Reducing Tee | ASTM A234, ASME SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

| Low Temperature Carbon Steel Unequal / Reducing Tee | ASTM A420 WPL3, A420 WPL6 |

| Alloy Steel Unequal / Reducing Tee | ASTM / ASME A/SA 234 GR. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

| Nickel Alloy Unequal / Reducing Tee | ASTM B336, ASME SB336, Níquel 200 (UNA No. No 2200), Níquel 201 (UNA No. N02201), Monel 400 (UNA No. N04400), Monel 500 (UNA No. N05500), Inconel 800 (UNA No. N08800), Inconel 825 (UNA No. N08825), Inconel 600 (UNA No. N06600), Inconel 625 (UNA No. N06625), Inconel 601 (UNA No. N06601), Hastelloy C 276 (UNA No. N10276), Aliatge 20 (UNA No. N08020), Titani (Grau I & II), Cupro-níquel 70/30, CuNi10Fe1Mn, CuNi30Mn1Fe. |

Buttweld Reducing Tee Manufacturing Standards

| Estàndard ASME | ASME/ANSI B16.9, ASME/ANSI B16.28, MSS-SP-43 |

| El teu estàndard | DIN28011, DIN2617, DIN2616, DIN2615, DIN2605 |

| Un estàndard | EN10253-2, EN10253-1 |

| ASME B16.25 | Buttwelding Ends |

| ASME B16.9 | Factory-Made Wrought Fittings Buttwelding |

| ASME B16.28 | Wrought Steel Reducing Tees and Buttwelding Returns |

| ASTM A403 – ASME SA403 | Standard Specification for Wrought Austenitic SS Piping Fitting |

| MSS SP-43 | Wrought & Fabricated Butt-Welding Fitting for Low Pressure, Aplicacions resistents a la corrosió |

DIMENSIONS OF BUTTWELD REDUCING TEE – ANSI 16.9

| Mida nominal del tub | Outside diameter

at bevel |

De centre a extrem | |||

| Run | Outlet | Run | Outlet | Run (C) | Outlet (M) |

| 1/2″ | 1/4″

3/8″ |

21.3 | 13.7

17.3 |

25 | 25 |

| 3/4″ | 3/8″

1/2″ |

26.7 | 17.3

21.3 |

29 | 29 |

| 1polzada | 1/2″

3/4″ |

33.4 | 21.3

26.7 |

38 | 38 |

| 1 1/4polzada | 1/2″

3/4″ 1″ |

42.2 | 21.3

26.7 33.4 |

48 | 48 |

| 1 1/2polzada | 1/2″

3/4″ 1″ 1 1/4″ |

48.3 | 21.3

26.7 33.4 42.2 |

57 | 57 |

| 2″ | 3/4″

1″ 1 1/4″ 1 1/2″ |

60.3 | 26.7

33.4 42.2 48.3 |

64 | 44

51 57 60 |

| 2 1/2″ | 1″

1 1/4″ 1 1/2″ 2″ |

73.0 | 33.4

42.2 48.3 60.3 |

76 | 57

64 67 70 |

| 3″ | 1 1/4″

1 1/2″ 2″ 2 1/2″ |

88.9 | 42.2

48.3 60.3 73.0 |

86 | 70

73 76 83 |

| 3 1/2″ | 1 1/2″

2″ 2 1/2″ 3″ |

101.6 | 48.3

60.3 73.0 88.9 |

95 | 79

83 89 92 |

| 4″ | 1 1/2″

2″ 2 1/2″ 3″ 3 1/2″ |

114.3 | 48.3

60.3 73.0 88.9 101.6 |

105 | 86

89 95 98 102 |

| 5″ | 2″

2 1/2″ 3″ 3 1/2″ 4″ |

141.3 | 60.3

73.0 88.9 101.6 114.3 |

124 | 105

108 111 114 117 |

| 6″ | 2 1/2″

3″ 3 1/2″ 4″ 5 |

168.3 | 73.0

88.9 101.6 114.3 141.3 |

143 | 121

124 127 130 137 |

| 8″ | 3 1/2″

4″ 5″ 6″ |

219.1 | 101.6

114.3 141.3 168.3 |

178 | 152

156 162 168 |

| 10″ | 4″

5″ 6″ 8″ |

273.0 | 114.3

141.3 168.3 219.1 |

216 | 184

191 194 203 |

| 12″ | 5″

6″ 8″ 10″ |

323.8 | 141.3

168.3 219.1 273.0 |

254 | 216

219 229 241 |

| 14″ | 6″

8″ 10″ 12″ |

355.6 | 168.3

219.1 273.0 323.8 |

279 | 238

248 257 270 |

| 16″ | 6″

8″ 10″ 12″ 14″ |

406.4 | 168.3

219.1 273.0 323.8 355.6 |

305 | 264

273 283 295 305 |

| 18″ | 8″

10″ 12″ 14″ 16″ |

457.0 | 219.1

273.0 323.8 355.6 406.4 |

343 | 298

308 321 330 330 |

| 20″ | 8″

10″ 12″ 14″ 16″ 18″ |

508.0 | 219.1

273.0 323.8 355.6 406.4 457.0 |

381 | 324

333 346 356 356 368 |

| 22″ | 10″

12″ 14″ 16″ 18″ 20″ |

559.0 | 273.0

323.8 355.6 406.4 457.0 508.0 |

419 | 359

371 381 381 394 406 |

| 24″ | 10″

12″ 14″ 16″ 18″ 20″ 22″ |

610.0 | 273.0

323.8 355.6 406.4 457.0 508.0 559.0 |

432 | 384

397 406 406 419 432 432 |

ASME B16.9 Buttweld Reducing Tee Weight Chart

| DN | NPS | STD | 40 | XS | 80 | 160 | XXS |

| 40 | 1 1/2 | 0.9 | 0.9 | 1.3 | 1.3 | 1.5 | 1.3 |

| 50 | 2 | 1.5 | 1.5 | 2.2 | 2.2 | 2.7 | 3.4 |

| 65 | 2 1/2 | 2.7 | 2.7 | 3.0 | 3.0 | 3.1 | 3.8 |

| 80 | 3 | 3.8 | 3.8 | 4.4 | 4.4 | 5.6 | 6.1 |

| 90 | 3 1/2 | 4.6 | 4.6 | 5.9 | 5.9 | ||

| 100 | 4 | 6.5 | 6.5 | 7.7 | 7.7 | 10.2 | 12.9 |

| 15 | 1/2 | 0.21 | 0.2 | 0.2 | 0.2 | ||

| 20 | 3/4 | 0.2 | 0.2 | 0.3 | 0.3 | ||

| 25 | 1 | 0.3 | 0.3 | 0.5 | 0.5 | ||

| 32 | 1 1/4 | 0.6 | 0.6 | 0.7 | 0.7 | ||

| 125 | 5 | 9.7 | 9.7 | 13.5 | 13.5 | 19.8 | 25.7 |

| 150 | 6 | 14 | 14 | 19.3 | 19.3 | 34 | 30.6 |

| 200 | 8 | 24.5 | 24.5 | 34.5 | 34.5 | 50 | 47.7 |

| 250 | 10 | 41.3 | 41.3 | 58.4 | 67.5 | 111.2 | 84.7 |

| 300 | 12 | 65 | 69 | 76.5 | 105 | 158 | 129 |

| 350 | 14 | 83 | 96 | 104 | 142 | 232 | |

| 400 | 16 | 110 | 120 | 120 | 187 | 335 | |

| 450 | 18 | 132 | 170 | 159 | 263 | 564 | |

| 500 | 20 | 168 | 240 | 192 | 356 | 756 | |

| 550 | 22 | 185 | 209 | 416 | 1002 | ||

| 600 | 24 | 222 | 345 | 251 | 548 | 1215 |

ASME B16.9 Reducing Tee Dimensional Tolerance

| Mida nominal del tub | 1/2 a 2.1/2 | 3 a 3.1/2 | 4 | 5 a 8 | 10 a 18 | 20 a 24 | 26 a 30 | 32 a 48 |

| Inside Dia at End | 0.8 | 1.6 | 1.6 | 1.6 | 3.2 | 4.8 | +6.4

-4.8 |

+6.4

-4.8 |

| Outside Dia

a Bevel (D) |

+1.6

-0.8 |

1.6 | 1.6 | +2.4

-1.6 |

+4

-3.2 |

+6.4

-4.8 |

+6.4

-4.8 |

+6.4

-4.8 |

| Center to End (C / M) | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 5 |

| Wall Thk (t) | Ni menys que 87.5% of Nominal Wall Thickness | |||||||

ASME B16.9 Reducing Tee Angularity Tolerance

| ND | Angle de descàrrega màxim | Max fora de l'avió |

| Q | P | |

| 1/2 a 4 | 1 | 2 |

| 5 a 8 | 2 | 4 |

| 10 a 12 | 3 | 5 |

| 14 a 16 | 3 | 7 |

| 18 a 24 | 4 | 10 |

| 26 a 30 | 5 | 10 |

| 32 a 42 | 5 | 13 |

| 44 a 48 | 5 | 20 |

AVAILABLE TYPES OF BUTTWELD REDUCING TEE

| Buttweld Unequal Tee | ASME B16.28 Buttweld Reducing Pipe Tees |

| Hastelloy Pipe Reducing Tees | Titanium Buttweld Reducing Tee |

| High Nickel Alloy Unequal Tee | Inconel Butt weld Reducing Tee |

| ANSI B16.9 Buttweld Reducing Tee | ASME B16.9 Butt weld Unequal Tee |

| Steel Reducing Tee Pipe Fittings | Butt Weld Reducing Tee |

| Stainless Steel Unequal Tee | SS Unequal Tees |

| Welded Butt weld Unequal Tee | Seamless Butt weld Unequal Tee |

| Carbon Steel Reducing Tee | High Quality Unequal Tee |

| Copper Nickel Unequal Tee | Duplex Steel Buttweld Reducing Tee |

| Super Duplex Steel Buttweld Reducing Tee | ASTM A403 Stainless Steel Unequal Tees |

Reducing Tee Buttweld Fittings – Industries & Aplicacions

Our Reducing Tee Buttweld Fittings is used in various applications and industries. Below are a few of them:

- Oil & Gas Industries

- Gas Processing Industries

- Food Processing Industries

- Petrochemical Industries

- Chemical Industries

- Power Generation Industries

- Sugar Industries

- Fertilizers Industries

Proveïdor de canonades d'acer inoxidable Wenzhou Kaixin Xina

Proveïdor de canonades d'acer inoxidable Wenzhou Kaixin Xina