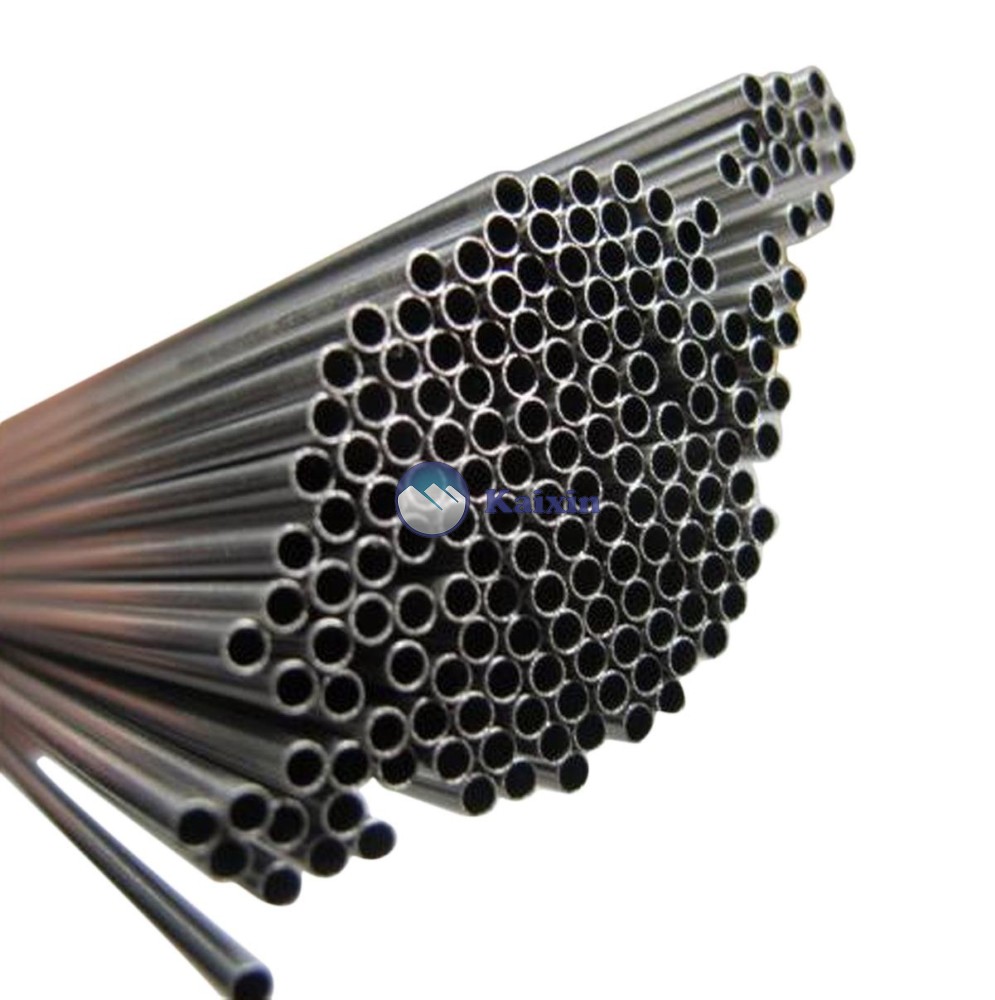

Stainless Steel Capillary Tube is a type of pipe made from stainless steel, which is a corrosion-resistant metal alloy containing at least 10.5% chrom. The chromium forms a protective layer on the surface of the steel, preventing rust and other types of corrosion from occurring. Stainless steel pipes are commonly used in various industrial applications, such as oil and gas, food and beverage, pharmaceuticals, and chemical processing, as well as in residential and commercial plumbing systems. They are also popular as decorative features in architectural and interior design. Stainless steel pipes come in different grades, sizes, and shapes, with the most common being round, náměstí, and rectangular. They can also be welded or seamless, depending on the intended use and application.

STAINLESS STEEL CAPILLARY TUBE SPECIFICATION

| Stainless Steel Capillary Tube Size Range | 0.35mm to 6.35mm OD in thickness ranging from 0.08mm to 1.2mm. |

| Thickness | 1mm to 20mm, SCH 5/5S, 10/10S, 20/20S, 40/40S, 80/80S, 120/120S, 160/160S as per ANSI B36.19/36.10 |

| Tloušťka stěny | 0.08 – 0.2 mm |

| Vnější průměr | 0.3 –12.0 mm |

| Specification | ASME / ASTM A213, ASTM A688 / A688M – 08, ASTM A803 / A803M, ASTM A556 / A556M, ASME SA556, ASME SA688 |

| Material | SS 304, SS 304L, SS 316, SS 316L |

| Finish | Pickled, Polished, Bright Annealed, Electrolytic Polished |

| Form | Round, Strait, Hydraulic etc. |

| Typ | As Welded, EFW, AKR, Bezešvé, Semi Seamless, Bead Removed |

| Mill Test Certificate | EN10204 3.1 |

| Packing | Sleeved, Ends Capped, Wooden Boxed |

Stainless Steel Hypodermic Tubing

| American Standard (ASTM) | TP304, TP304L, TP310S, TP316, TP316L, TP316Ti, TP321, TP347, 904L Etc |

| European Standard (V) | 1.4301, 1.4306, 1.4845, 1.4401, 1.4404, 1.4571, 1.4541, 1.4550, 1.4539 Etc |

| German Standards | X5CrNi18-10, X2CrNi19-11, X12CrNi25-21, X5CrNi17-12-2, X5CrNi17-12-3, X2CrNiMo18-14-3, X6CrNiTi18-10, X6CrNiTb18-10 Etc |

SS Capillary Tube Chemical Composition

| Elements | 304L (wt%) UNS S30403 | 304 (wt%) UNS S30400 | 316L (wt%) UNS S31603 | 316 (wt%) UNS S31600 |

|---|---|---|---|---|

| (C) Carbon, max | 00.035 | 00.08 | 00.035 | 00.08 |

| (Mn) Manganese, max | 2 | 2 | 2 | 2 |

| (P) Phosphorus, max | 00.045 | 00.045 | 00.045 | 00.045 |

| (S) Sulfur, max | 00.03 | 00.03 | 00.03 | 00.03 |

| (Si) Silicon, max | 1 | 1 | 1 | 1 |

| (Ni) Nikl | 8.0 – 12.0 | 8.0 – 11.0 | 10.0 – 14.0 | 10.0 – 14.0 |

| (Cr) Chromium | 18.0 – 20.0 | 18.0 – 20.0 | 16.0 – 18.0 | 16.0 – 18.0 |

| (Mo) Molybdenum | N/A | N/A | 2.0 – 3.0 | 2.0 – 3.0 |

| (Fe) Iron | Balance. | Bal. | Rest. | Bal. |

| (Cu) Copper | N/A | N/A | N/A | N/A |

| (N) Nitrogen | N/A | N/A | N/A | N/A |

DIMENSIONS AND WALL THICKNESS OF STAINLESS STEEL CAPILLARY TUBE

| Gauge | Outside Diameter Tolerance mm | Regular Wall (RW) mm | Thin Wall (TW) mm | Extra Thin Wall (XTW) mm | Ultra Thin Wall (UTW) mm |

| 30 | 0.304 – 0.317 | 0.064 – 0.089 | |||

| 29 | o.330 – 0.342 | 0.064 – 0.089 | |||

| 28 | 0.355 – 0.368 | 0.076 – 0.102 | |||

| 27 | 0.406 – 0.419 | 0.089 – 0.115 | 0.064 – 0.089 | ||

| 26 | 0.457 – 0.469 | 0.089 – 0.114 | |||

| 25 | 0.508 – 0.520 | 0.115 – 0.140 | 0.089 – 0.114 | ||

| 24 | 0.558 – 0.571 | 0.114 – 0.140 | 0.089 – 0.114 | 0.051 – 0.102 | |

| 23 | 0.635 – 0.647 | 0.140 – 0.165 | 0.089 – 0.114 | 0.051 – 0.102 | |

| 22 | 0.711 – 0.723 | 0.140 – 0.165 | 0.096 – 0.121 | 0.077 – 0.102 | 0.051 – 0.102 |

| 21 | 0.812 – 0.825 | 0.140 – 0.165 | 0.102 – 0.127 | 0.051 – 0.102 | |

| 20 | 0.901 – 0.914 | 0.108 – 0.165 | 0.108 – 0.134 | ||

| 19 | 1.054 – 1.079 | 0.166 – 0.216 | 0.102 – 0.140 | 0.070 – 0.108 | |

| 18 | 1.257 – 1.282 | 0.191 – 0.241 | 0.127 – 0.165 | 0.083 – 0.121 | 0.051 – 0.102 |

| 17 | 1.460 – 1.485 | 0.177 – 0.229 | 0.115 – 0.152 | 0.083 – 0.127 | 0.057 – 0.102 |

| 16 | 1.638 – 1.663 | 0.204 – 0.254 | 0.127 – 0.165 | 0.096 – 0.133 | 0.070 – 0.121 |

| 15 | 1.816 – 1.841 | 0.204 – 0.254 | 0.127 – 0.165 | 0.096 – 0.134 | 0.070 – 0.121 |

| 14 | 2.082 – 2.133 | 0.216 – 0.292 | 0.165 – 0.229 | 0.114 – 0.165 | 0.076 – 0.134 |

| 13 | 2.387 – 2.438 | 0.267 – 0.343 | 0.191 – 0.267 | ||

| 12 | 2.743 – 2.749 | 0.267 – 0.321 | |||

| 11 | 3.023 – 3.073 | 0.293 – 0.368 | 0.216 – 0.292 | ||

| 10 | 3.378 – 3.429 | 0.318 – 0.394 | 0.216 – 0.292 |

Mechanical Strength Table of Stainless Steel Capillary Tubing

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 304/ 304L | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 304H | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 40 % |

| 310 / 310S / 310H | 7.9 g/cm3 | 1402 °C (2555 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 40 % |

| 306/ 316H | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 316L | 8.0 g/cm3 | 1399 °C (2550 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 317 | 7.9 g/cm3 | 1400 °C (2550 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 321 | 8.0 g/cm3 | 1457 °C (2650 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 347 | 8.0 g/cm3 | 1454 °C (2650 °F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| 904L | 7.95 g/cm3 | 1350 °C (2460 °F) | Psi 71000 , MPa 490 | Psi 32000 , MPa 220 | 35 % |

AVAILABLE STOCK OF SS CAPILLARY TUBE

| Kapilární trubice z nerezové oceli | Stainless Steel Seamless Capillary Tube |

| Stainless Steel Bright Polished Capillary Tube | Stainless Steel Capillary Tubing |

| Stainless Steel Seamless Capillary Tube | SS Capillary Tubing |

| Seamless Stainless Steel Capillary Tube | ESI Stainless Steel Capillary Tube |

| Kapilární trubice z nerezové oceli | Stainless Steel Welded Capillary Tube |

| 304 Kapilární trubice z nerezové oceli | 316L Stainless Steel Capillary Tube |

| Nerez 201 Capillary Tubes | Polished 316 Kapilární trubice z nerezové oceli |

| Nerez 202 Capillary Tube | Nerez 304 / 304L Capillary Tube |

| SS Capillary Tube | 316 Kapilární trubice z nerezové oceli |

| 304 Kapilární trubice z nerezové oceli | ASTM304 Stainless Steel Capillary Tube |

| stainless steel Capillary tubing | od 8mm x 6mm od 304 Kapilární trubice z nerezové oceli |

| Mirror Polished stainless steel Capillary Tube | Stainless Steel Electropolished Capillary Tubes |

| high quality stainless steel Capillary Tube | 316 Kapilární trubice z nerezové oceli |

| stainless steel Capillary Tube | ASTM / ASME Stainless Steel Capillary Tube |

| stainless steel Capillary tubing | SS 304l Capillary Tube |

| Stainless steel Capillary tube | SS 316L Capillary Tube |

| stainless steel Capillary tubing | Stainless Steel Welded Capillary Tube |

| SS welded Capillary Tube | Stainless Steel Seamless Capillary Tube |

| Bright Polished, Cleaned, Passivated Capillary Tubes | Steel Capillary Tubes |

| 316 Stainless Steel Capillary Tubing | Nerez 1/16 in. Capillary Tubing |

| Capillary tubing | AISI Stainless Steel Capillary Tubes |

| Kapilární trubice z nerezové oceli | Ss Capillary Tube |

| Steel Capillary Tube | Stainless Capillary Tube |

| UNS S30400 SS Capillary Tubes | Stainless Steel Electropolished Capillary Tubes |

| ASTM/ASME SS Capillary Tubes | AISI Stainless Steel Capillary Tubes |

| SS Semi Seamless Capillary Tubes | Bright Polished, Cleaned, Passivated Capillary Tubes |

| SS 316 UNS S31600 Capillary Tubes | Steel 317 Z 1.4449 Capillary Tubes |

| TP 410 SS Capillary Tubes | Stainless Steel Capillary Tubes |

| Stainless Steel 321/321H Capillary Tubing | 904L Stainless Steel Capillary Tubes |

| SS 446 ERW Capillary Tubes | 347H SS EFW Capillary Tubes |

| Stainless Steel Seamless Capillary Tube | SS Welded Capillary Tubes |

Dodavatel trubek z nerezové oceli Wenzhou Kaixin Čína

Dodavatel trubek z nerezové oceli Wenzhou Kaixin Čína