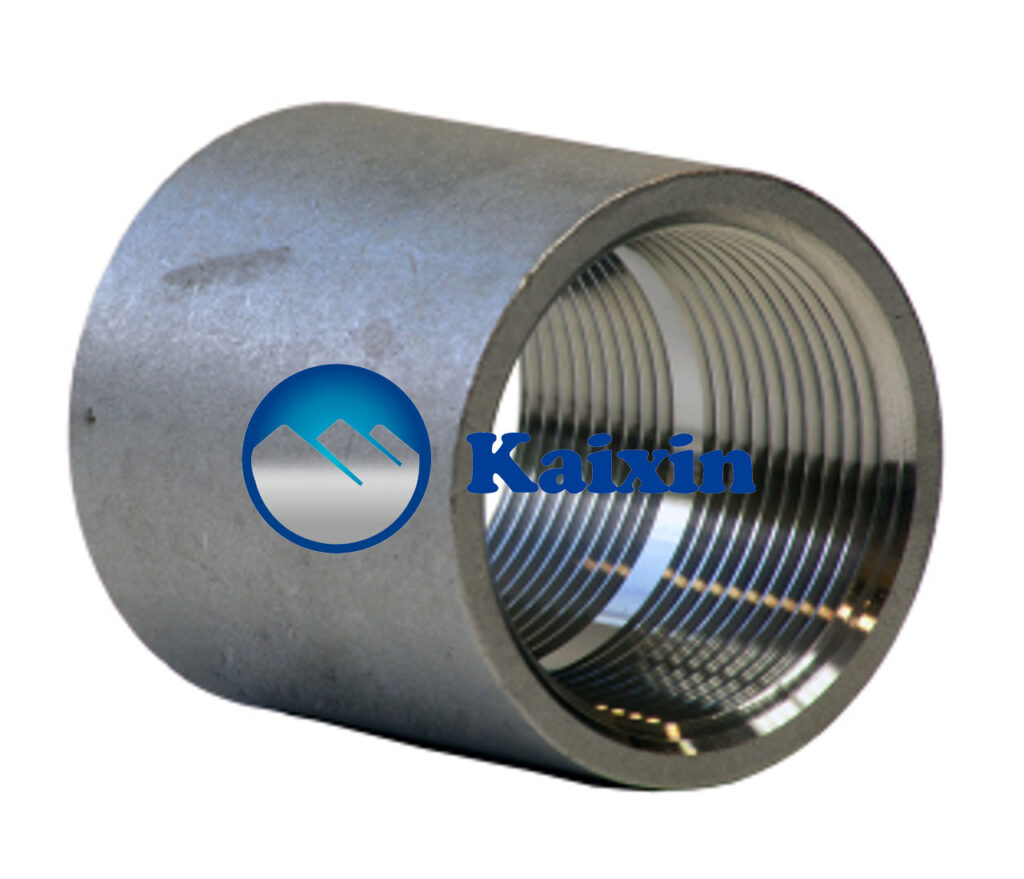

What is Threaded Full Coupling?

A stainless steel threaded full coupling is a type of plumbing fitting that is used to join two pipes of equal diameter together. The coupling is typically made out of high-quality stainless steel, which makes it resistant to rust and corrosion. The threaded design of the coupling allows for easy installation and removal, and it can be used in a variety of different applications, including water supply, oil and gas, og kemisk forarbejdning.

The full coupling design of this fitting means that it is a complete coupling that covers the entire length of both pipes, providing a tight and secure seal. This design is ideal for applications where a strong and reliable connection is necessary, such as in high-pressure or high-temperature environments.

Stainless steel threaded full couplings are available in a variety of sizes and thread types, allowing them to be used with different pipe materials and configurations. When selecting a coupling, it is important to ensure that it is compatible with the pipe material and size being used to avoid leaks or other connection issues.

samlet set, a stainless steel threaded full coupling is a durable and versatile plumbing fitting that can provide a secure and long-lasting connection between two pipes.

Specifications of ASME B16.11 Threaded Full Coupling

| Størrelser | 1/8″NB TO 4″NB IN (DN6 x DN100) |

| Standarder | ASME/ANSI B16.11, MSS SP-79, MSS-SP-95, 83, 97,DIN28011, DIN2617, DIN2616, DIN2615, DIN2605,EN10253-2, EN10253-1 |

| Dimensioner | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Tykkelse | Skema 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS og så videre. |

| Pressure Class | 3000 LBS, 6000 LBS, 9000 LBS |

| Fra | Gevind / Screwed Coupling, Threaded Forged Full Coupling |

| Grades&Materialer | ASTM / ASME A/SA 182 – F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L.ASTM / ASME A/SA 182 – F44, F45, F51, F53, F55, F60, F61.ASTM / ASME SB 564 / 160 / 472 – UNS 2200 (NICKEL 200), OS 4400 (MONEL 400), OS 8825 INCONEL (825), OS 6600(INCONEL 600), OS 6601 (INCONEL 601), OS 6625 (INCONEL 625), OS 10276 (HASTELLOY C 276), OS 2201 (NICKEL 201), (ALLOY 20 / 20 CB 3),ASTM / ASME SB 61 / 62 / 151 / 152 – UNS NO. C 92200, UNS NO. C 83600, UNS NO. 70600, 71500, C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30), UNS NO C 10100, C 10200, C 10300, C 10800, C 12000, C 12200,ASTMA 105/A694/ A350 LF3/A350 LF2 – F42, F46, F52, F56,F60, F65, F70, ASTM A182 – F1, F5, F9, F11, F22, F91,Brass CA 360, CA 345 and CA 377 / SAE J530, SAE J531 and ASA |

| Type | Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT |

ANSI B16.11 Stainless Steel Threaded Full Coupling Manufacturing Standards

| ASME Standard | ASME/ANSI B16.11, MSS SP-79, MSS-SP-95, 83, 97 |

| DIN Standard | DIN28011, DIN2617, DIN2616, DIN2615, DIN2605 |

| EN Standard | EN10253-2, EN10253-1 |

| ASME B16.11 | Gevind |

| ASTM A182 – ASME SA182 | Standard Specification for Wrought Austenitic SS Piping Threaded Fittings |

| MSS SP-95 | Threaded Full Coupling |

MATERIALS AND GRADES OF ASME B16.11 THREADED FULL COUPLING

ASME B16.11 Stainless Steel Threaded Full Coupling Pipe Fittings:ASTM / ASME A/SA 182 – F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L.

ASME B16.11

Duplex & Super Duplex Threaded Full Coupling Pipe Fittings :ASTM / ASME A/SA 182 – F44, F45, F51, F53, F55, F60, F61.

ASME B16.11 Nickel Alloy Threaded Full Coupling Pipe Fittings:ASTM / ASME SB 564 / 160 / 472 – UNS 2200 (NICKEL 200), OS 4400 (MONEL 400), OS 8825 INCONEL (825), OS 6600(INCONEL 600), OS 6601 (INCONEL 601), OS 6625 (INCONEL 625), OS 10276 (HASTELLOY C 276), OS 2201 (NICKEL 201), (ALLOY 20 / 20 CB 3)

ASME B16.11 Copper Alloy Threaded Full Coupling Pipe Fittings:ASTM / ASME SB 61 / 62 / 151 / 152 – UNS NO. C 92200, UNS NO. C 83600, UNS NO. 70600, 71500, C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30), UNS NO C 10100, C 10200, C 10300, C 10800, C 12000, C 12200

ASME B16.11 Carbon Steel Threaded Full Coupling Pipe Fittings :ASTMA 105/A694/ A350 LF3/A350 LF2 – F42, F46, F52, F56, F60, F65, F70

ASME B16.11 Alloy Steel Threaded Full Coupling Pipe Fittings:ASTM A182 – F1, F5, F9, F11, F22, F91

ASME B16.11 Brass Threaded Full Coupling Pipe Fittings:Brass CA 360, CA 345 and CA 377 / SAE J530, SAE J531 and ASA

High Pressure Threaded Full Coupling Types by Size, klasse, and Wall Thickness

| Description | Class Designation | ||

| 2000 | 3000 | 6000 | |

| Threaded Full Coupling | 1/2 – 4 | 1/2 – 2 | 1/2 – 2 |

| 1/2 – 4 | 1/2 – 2 | 1/2 – 2 | |

| 1/2 – 4 | 1/2 – 2 | 1/2 – 2 | |

| Pipe Wall | SCH 80 / XS | SCH 160 | XXS |

Threaded Full Coupling Dimensions

Threaded Full Coupling Dimensions Drawing

| NOMINAL PIPE SIZE | END TO END | MINIMUM LENGTH OF THREAD | OUTSIDE DIAMETER | ||

| Inch. | Full Coupling | #3000 | #6000 | ||

| EN | B | C | D | D | |

| 1/8 | 32 | 6.7 | 6.4 | 16 | 22 |

| 1/4 | 35 | 10.2 | 8.1 | 19 | 25 |

| 3/8 | 38 | 10.4 | 9.1 | 22 | 32 |

| 1/2 | 48 | 13.6 | 10.9 | 28 | 38 |

| 3/4 | 51 | 13.9 | 12.7 | 35 | 44 |

| 1 | 60 | 17.3 | 14.7 | 44 | 57 |

| 1 1/4 | 67 | 18 | 17 | 57 | 64 |

| 1 1/2 | 79 | 18.4 | 17.8 | 64 | 76 |

| 2 | 86 | 19.2 | 19 | 76 | 92 |

| 2 1/2 | 92 | 28.9 | 23.6 | 92 | 108 |

| 3 | 108 | 30.5 | 25.9 | 108 | 127 |

| 4 | 121 | 33 | 27.7 | 140 | 159 |

| All Dimensions are in mm | |||||

ASME B16.11 Screwed / Threaded Full Coupling Dimensions Tolerance

| Threaded Full Coupling Pipe Fittings Dimension (NPS) | Uden for Diameter ved Bevel |

Indenfor Diameter ved Slutningen |

Wall Thickness T | Center-to-End Dimension EN ,C ,B |

Over-all Length H |

Over-all Length F |

| 1/2 til 2-1/2 | +0.06 | Not less than 87.5% of nominal thickness |

+/- 0.06 | +/- 0.06 | +/- 0.12 | |

| -0.03 | ||||||

| 3 til 3-1/2 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.12 | |

| 4 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.12 | |

| 5 til 8 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.06 | +/- 0.25 | |

| 10 til 18 | +0.16 | +/- 0.12 | +/- 0.09 | +/- 0.09 | +/- 0.25 | |

| -0.12 | ||||||

| 20 til 24 | +0.25 | +/- 0.19 | +/- 0.09 | +/- 0.09 | +/- 0.25 | |

| -0.19 | ||||||

| 26 til 30 | +0.25 | +/- 0.19 | +/- 0.12 | +/- 0.19 | +/- 0.38 | |

| -0.19 | ||||||

| 32 til 48 | +0.25 | +/- 0.19 | +/- 0.19 | +/- 0.19 | +/- 0.38 | |

| -0.19 |

ASME B16.11 Threaded Full Coupling Angularity Tolerance

| ND | Max off vinkel | Max væk fra flyet |

| Q | P | |

| 1/2 -en 4 | 1 | 2 |

| 5 -en 8 | 2 | 4 |

| 10 -en 12 | 3 | 5 |

| 14 -en 16 | 3 | 7 |

| 18 -en 24 | 4 | 10 |

| 26 -en 30 | 5 | 10 |

| 32 -en 42 | 5 | 13 |

| 44 -en 48 | 5 | 20 |

Threaded Full Pipe Coupling Pressure Ratings Formula

| ASME B16.11 Full Coupling Pressure-Temperature ratings | |||||

| Temperature | klasse | ||||

| 150 | 300 | ||||

| 1/4 – 1 inch. | 1 1/4 – 2 inch. | 2 1/2 – 3 inch. | |||

| (oF) | (oC) | ||||

| -20 til 150 | -29 til 66 | 300 | 2000 | 1500 | 1000 |

| 200 | 93 | 265 | 1785 | 1350 | 910 |

| 250 | 121 | 225 | 1575 | 1200 | 825 |

| 300 | 149 | 185 | 1360 | 1050 | 735 |

| 350 | 177 | 150 | 1150 | 900 | 650 |

| 400 | 204 | – | 935 | 750 | 560 |

| 450 | 232 | – | 725 | 600 | 475 |

| 500 | 260 | – | 510 | 450 | 385 |

| 550 | 288 | – | 300 | 300 | 300 |

ASME B16.11 Threaded Full Coupling Weight

ASME B16.11 Threaded full Coupling drawing

| DN | Nom. Pipe Size | Center to End Coupling

W |

Center to End Cap

P |

Udvendig diameter | End Wall

Tykkelse G Min. |

ength of Thread

Min. (1) |

||||

| 000& 6000 | 3000 | 6000 | 3000 | 6000 | 3000 | 6000 | B | L2 | ||

| 6 | 1/8″ | 32 | 19 | 16 | 4.8 | 6.4 | 6.7 | |||

| 8 | 1/4″ | 35 | 25 | 27 | 19 | 25 | 4.8 | 6.4 | 8.1 | 10.2 |

| 10 | 3/8″ | 38 | 25 | 27 | 22 | 32 | 4.8 | 6.4 | 9.1 | 10.4 |

| 15 | 1/2″ | 48 | 32 | 33 | 28 | 38 | 6.4 | 7.9 | 10.9 | 13.6 |

| 20 | 3/4″ | 51 | 37 | 38 | 35 | 44 | 6.4 | 7.9 | 12.7 | 13.9 |

| 25 | 1″ | 60 | 41 | 43 | 44 | 57 | 9.7 | 11.2 | 14.7 | 17.3 |

| 32 | 1-1/4″ | 67 | 44 | 46 | 57 | 64 | 9.7 | 11.2 | 17.0 | 18.0 |

| 40 | 1-1/2″ | 79 | 44 | 48 | 64 | 76 | 11.2 | 12.7 | 17.8 | 18.4 |

| 50 | 2″ | 86 | 48 | 51 | 76 | 92 | 12.7 | 15.7 | 19.0 | 19.2 |

| 65 | 2-1/2″ | 92 | 60 | 64 | 92 | 108 | 15.7 | 19.0 | 23.6 | 28.9 |

| 80 | 3″ | 108 | 65 | 68 | 108 | 127 | 19.0 | 22.4 | 25.9 | 30.5 |

| 100 | 4″ | 121 | 68 | 75 | 140 | 159 | 22.4 | 28.4 | 27.7 | 33.0 |

(1) Dimensions in Millimeters

(2) Dimension B is minimum length of perfect thread. The length of useful thread (B plus threads with fuly formed roots and flat crests) shall not be less than L2(effective length of external thread) required by American National Standard for Pipe Threads (ANSI/ASME B1.20. 1)

TYPES OF ASME B16.11 THREADED FULL COUPLING

| Forged Threaded Full Coupling | Forged Screwed Reducing Coupling |

| Stainless Steel Screwed Full Coupling | SS Forged Threaded Full Coupling |

| Carbon Steel Threaded Full Coupling | High Quality Threaded Coupling |

| ASTM A182 Threaded Full Coupling | Duplex Steel Threaded Full Coupling |

| Titanium Forged Threaded Full Coupling | Inconel Threaded Forged Coupling |

| Super Duplex Steel Screwed Coupling | Copper Nickel Threaded Coupling |

| 150 lb. Threaded Full Coupling Fittings | 6000LBS Forged Steel Threaded Coupling |

| ASME B16.11 Forged Threaded Full Coupling | Threaded Forged Full Coupling 3000LBS |

| ANSI B16.11 Forged Threaded Full Coupling | BS 3799 Forged Screwed Full Coupling |

| High Nickel Alloy Threaded Full Coupling | Hastelloy Screwed Full Coupling Pipe Fittings |

Applications Of ASME B 16.11 Threaded Full Coupling

- ASME B 16.11 Threaded Full Coupling used in Chemical and petrochemical processing

- ASME B 16.11 Threaded Full Coupling used in refineries

- ASME B 16.11 Threaded Full Coupling used in electronics

- ASME B 16.11 Threaded Full Coupling used in fertilizer

- ASME B 16.11 Threaded Full Coupling used in power plant

- ASME B 16.11 Threaded Full Coupling used in nuclear power

- ASME B 16.11 Threaded Full Coupling used in oil and gas

- ASME B 16.11 Threaded Full Coupling used in paper industries

Leverandør af rustfrit stål, Wenzhou Kaixin Kina

Leverandør af rustfrit stål, Wenzhou Kaixin Kina