A buttweld 90 degree long radius elbow is a type of pipe fitting that is used to change the direction of flow in a pipeline by 90 degrees. The elbow has a longer radius than a standard 90 codo grado, which helps to reduce friction and flow resistance in the pipeline. The fitting is typically made from steel or other alloys and is designed to be welded to the ends of two pipes. This creates a permanent and leak-free connection that is ideal for use in high-pressure applications. The buttweld 90 degree long radius elbow is commonly used in the oil and gas industry, as well as in power generation and other industrial applications.

Buttweld 90° Long Radius Elbow Pipe Fitting Specifications

| Diámetro exterior (OD) | Seamless 90° Long Radius Elbow (1/2″~24″), ACRE / Fabricated Elbow / soldado (1/2″~48″) |

| Estándares | ANSI – B 16.9, ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’, API 590-605, ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings”, ASME B16.25 – ‘Buttwelding Ends’, ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’, MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Dimensiones | ASME/ANSI B16.9, MSS-SP-43 Tipo A, MSS-SP-43 Tipo B, JIS B2312, JIS B2313, ASME B16.28 |

| Cronograma | Horario 5S, 10S, 20S, T10, S20, S30, ETS, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS y etc.. |

| Radio de curvatura | R=1D – 10D, 15D, 20D |

| De | 90° Long Radius Elbow, Butt weld 90° Long Radius Elbow. |

| Servicios de valor agregado | Hot Dipped Galvanizing, Electro Polish, Epoxy & FBE Coating, Sand Blasting, Soldering, Enhebrado |

| Materiales | 304/L/H/LN, 316/L/H/LN/Ti, 321/h, 317/L/LN, 347/h, 310S/H, N08904(904l), S31803,S32205, S32750, S32760, N02200, N02201, N04400, N06600, N06690, N06625, N06985(G3), N08028, N08800, N08810, N08811, N08825Surface,Monel, Níquel, Inconel, Hastalloy, Titanio, Tantalum, Acero inoxidable, Alloy Steel, Carbon Steel, Cuproníquel 90/10 & 70/30, Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, DE 1.4301, DIN1.4306, DE 1.4401, DE 1.4404 |

| Tipo | Butt Weld (BW) / soldado / ACRE / fabricado |

| SS Melting Points | 1400-1450°C (WP304, WP304L), 1390-1440 °C (WP316L), 1370 – 1400 °C (WP316) |

90 DEGREE LONG RADIUS ELBOW – MATERIALS & GRADES

| Stainless Steel Buttweld 90 Codo de radio largo de grado | ASTM A403 WP316/316L, ASTM A403SA / A 774 WP-S, WP-W, WP-WX 304/304L, ASTM A182 F316L, 304l, DE 1.4301, DIN1.4306, DE 1.4401, DE 1.4404 |

| Dúplex & Super Duplex Steel Buttweld 90 Codo de radio largo de grado | ASTM A 815, ASME SA 815 Nº UNS S31803, S32205. EE. UU. S32750, S32950. Numero de Material. 1.4462 |

| Carbon Steel Buttweld 90 Codo de radio largo de grado | ASTM A234, ASME SA234 WPB , WPBW, ¿Por qué? 42, ¿Por qué? 46, ¿Por qué? 52, WPH 60, ¿Por qué? 65 & ¿Por qué? 70. |

| Low Temperature Carbon Steel 90 Codo de radio largo de grado | ASTM A420 WPL3, A420 WPL6 |

| Alloy Steel Buttweld 90 Codo de radio largo de grado | ASTM / ASME A/S.A 234 Gramo. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

| Nickel Alloy Buttweld 90 Codo de radio largo de grado | ASTM B336, ASME SB336, Níquel 200 (SNU No. No2200), Níquel 201 (SNU No. N02201), Monel 400 (SNU No. N04400), Monel 500 (SNU No. N05500), Inconel 800 (SNU No. N08800), Inconel 825 (SNU No. N08825), Inconel 600 (SNU No. N06600), Inconel 625 (SNU No. N06625), Inconel 601 (SNU No. N06601), HastelloyC 276 (SNU No. N10276), Aleación 20 (SNU No. N08020), Titanio (Grado I & II), Cuproníquel 70/30, CuNi10Fe1Mn, CuNi30Mn1Fe. |

Soldadura a tope 90 Deg Long Radius Elbows Application Industries

- Petrochemical Industry

- Chemical Industry

- Oil and Gas Industry

- Pulpa & Paper Indusry

- Power Plant Industry

- Food Processing Industry

- Pharmaceuticals Industry

- Energy Industry

- Aerospace Industry

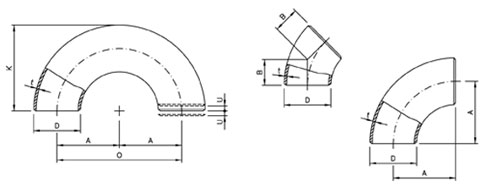

ASME B16.9 Buttweld 90° Long Radius Elbow Dimensions

ASME B16.9 Buttweld 90° Long Radius Elbow Dimension Drawing

| LONG RADIUS ELBOWS (R = 1,5 DAKOTA DEL NORTE) ANSI B 16.9 dimensions | ||||||

| pulgadas | DAKOTA DEL NORTE | milímetros | Center to center | Radius | Center to end | Back to face |

| D | O | A | B | K | ||

| 1/2 | 15 | 21,34 | 76,20 | 38,10 | 15,87 | 47,62 |

| 3/4 | 20 | 26,67 | 57,15 | 28,57 | 11,11 | 42,86 |

| 1 | 25 | 33,40 | 76,20 | 38,10 | 22,22 | 55,56 |

| 1 1/4 | 32 | 42,16 | 95,25 | 47,60 | 25,40 | 69,85 |

| 1 1/2 | 40 | 48,26 | 114,30 | 57,15 | 28,57 | 82,55 |

| 2 | 50 | 60,32 | 152,40 | 76,20 | 34,92 | 106,40 |

| 2 1/2 | 65 | 73,02 | 190,50 | 95,25 | 44,45 | 131,80 |

| 3 | 80 | 88,90 | 228,60 | 114,30 | 50,80 | 158,75 |

| 3 1/2 | 90 | 101,60 | 266,70 | 133,35 | 57,15 | 184,15 |

| 4 | 100 | 114,30 | 304,80 | 152,40 | 63,50 | 209,55 |

| 5 | 125 | 141,30 | 381,00 | 190,50 | 79,38 | 261,90 |

| 6 | 150 | 168,27 | 457,20 | 228,60 | 95,25 | 312,70 |

| 8 | 200 | 219,07 | 609,60 | 304,80 | 127,00 | 414,30 |

| 10 | 250 | 273,05 | 762,00 | 381,00 | 158,75 | 517,50 |

| 12 | 300 | 323,85 | 914,40 | 457,20 | 190,50 | 619,10 |

| 14 | 350 | 355,60 | 1066,80 | 533,40 | 222,25 | 711,20 |

| 16 | 400 | 406,40 | 1219,20 | 609,60 | 254,00 | 812,80 |

| 18 | 450 | 457,20 | 1371,60 | 685,80 | 285,74 | 914,40 |

| 20 | 500 | 508,00 | 1524,00 | 762,00 | 317,50 | 1016,00 |

| 22 | 550 | 558,80 | 1676,40 | 838,20 | 342,90 | 1117,60 |

| 24 | 600 | 609,60 | 1828,80 | 914,40 | 381,00 | 1219,20 |

| 28 | 700 | 711,20 | 2133,60 | 1066,80 | 441,90 | 1422,40 |

| Dimensions in mm. | ||||||

90 Degree Long Radius Elbow Dimensions Tolerance

| for all Pipe fittings | Elbows 90 deg | |||

| Nominal Pipe Size (NPS) | Espesor de pared t / t1 |

Outside Ø at Bevel |

Inside Ø at End |

Center to End Dim. A-B-C-M |

| 1/2 a 2 1/2 | Not | 1 | 0,8 | 2 |

| 3 a 3 1/2 | less than | 1 | 1,6 | 2 |

| 4 | +2 -1 | 1,6 | 2 | |

| 5 a 6 | 87,50% | +3 -1 | 1,6 | 2 |

| 8 | of nominal | 2 | 1,6 | 2 |

| 10 | thickness | +4 -3 | 3,2 | 2 |

| 12 a 18 | 3,2 | +4 -3 | 3 | |

| 20 a 24 | 4,8 | +6 -5 | 3 | |

| 26 a 30 | 4,8 | +7 -5 | 3 | |

| 32 a 48 | 4,8 | +7 -5 | 5 | |

ASME B16.9 90° Long Radius Elbow Angularity Tolerance

| DAKOTA DEL NORTE | Ángulo de salida máximo | Max fuera del avión |

| q | PAG | |

| 1/2 a 4 | 1 | 2 |

| 5 a 8 | 2 | 4 |

| 10 a 12 | 3 | 5 |

| 14 a 16 | 3 | 7 |

| 18 a 24 | 4 | 10 |

| 26 a 30 | 5 | 10 |

| 32 a 42 | 5 | 13 |

| 44 a 48 | 5 | 20 |

WEIGHT CHART OF 90 DEGREE LONG RADIUS ELBOW

| NPS pulgadas |

ELBOWS LR 90° | |||

| Sch. 5S |

Sch. 10S |

Sch. 40S |

Sch. 80S |

|

| 1/2 | 0.05 | 0.06 | 0.08 | 0.10 |

| 3/4 | 0.06 | 0.07 | 0.09 | 0.11 |

| 1 | 0.09 | 0.15 | 0.18 | 0.20 |

| 1 1/4 | 0.13 | 0.20 | 0.25 | 0.35 |

| 1 1/2 | 0.18 | 0.30 | 0.40 | 0.50 |

| 2 | 0.30 | 0.50 | 0.70 | 0.90 |

| 2 1/2 | 0.60 | 0.85 | 1.35 | 1.80 |

| 3 | 0.90 | 1.30 | 2.00 | 2.90 |

| 4 | 1.40 | 2.00 | 4.00 | 5.90 |

| 5 | 2.90 | 3.60 | 6.50 | 9.70 |

| 6 | 4.00 | 5.00 | 10.5 | 16.0 |

| 8 | 7.40 | 10.0 | 21.5 | 33.5 |

| 10 | 13.6 | 16.8 | 38.5 | 52.5 |

| 12 | 23.4 | 27.0 | 59.0 | 79.0 |

| 14 | 29.0 | 35.0 | 70.0 | 94.0 |

| 16 | 41.3 | 47.0 | 95.0 | 125 |

| 18 | 51.8 | 59.0 | 120 | 158 |

| 20 | 73.0 | 85.0 | 146 | 194 |

| 24 | 122 | 140 | 210 | 282 |

| Pesos aproximados en kg, densidad 8 kg/dm3 | ||||

AVAILABLE TYPES OF 90 DEGREE LONG RADIUS ELBOW

| Buttweld 90° Long Radius Elbow | Duplex Steel Buttweld 90° Long Radius Elbow |

| ASME B16.9 Butt weld 90° Long Radius Elbow | High Nickel Alloy 90° Long Radius Elbow |

| Stainless Steel 90° Long Radius Elbow | SS 90° Long Radius Elbow |

| High Quality 90° Long Radius Elbow | Seamless Butt weld 90° Long Radius Elbow |

| Welded Butt weld 90° Long Radius Elbowr | ASME B16.28 Buttweld 90° Long Radius Elbow |

| Carbon Steel 90° Long Radius Elbow | ANSI B16.9 Buttweld 90° Long Radius Elbow |

| Titanium Buttweld 90° Long Radius Elbow | Inconel Butt weld 90° Long Radius Elbow |

| ASTM A403 Stainless Steel 90° Long Radius Elbow | Butt Weld B16.9 90° Long Radius Elbow |

| Super Duplex Steel Buttweld 90° Long Radius Elbow | Copper Nickel 90° Long Radius Elbow |

| Steel 90° Long Radius Elbow | Hastelloy 90° Long Radius Elbow |

Proveedor de tubos de acero inoxidable Wenzhou Kaixin China

Proveedor de tubos de acero inoxidable Wenzhou Kaixin China