A Buttweld Pipe Equal Cross is a kind of Pipe Fitting that be utilized in the place where four pipes meet together. The Butt Weld cross may have one inlet and three outlets, or their inlets and one outlet. Buttweld Equal Cross Fittings are utilized in several industries for providing leak-free and torque free sealing in any piping or tubing connection. Offered in various grades Buttweld Equal Cross Fittings are reckoned for their close tolerances and excellent finishes.

The Equal Cross is one reason the pipe cross, similar to an Equal Tee, the butt weld Equal Cross means all the four ends of the cross are within the same diameter. This equal cross has four ends of the cross are in equal diameter. the stainless steel Equal Cross is obtainable in several specifications that adjust in standards, espesor de pared, types, forms.

Buttweld Equal Cross Pipe Fitting Specifications

| Tallas | Seamless Pipe Equal Cross ( 1/2″~24″), ACRE / soldado / Fabricated Pipe Equal Cross (1/2″~48″) |

| Estándares | ANSI – B 16.9, ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’, API 590-605, ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings”, ASME B16.25 – ‘Buttwelding Ends’, ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’, MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Dimensiones | ASME/ANSI B16.9, MSS-SP-43 Tipo A, MSS-SP-43 Tipo B, JIS B2312, JIS B2313, ASME B16.28 |

| Espesor | Horario 5S, 10S, 20S, T10, S20, S30, ETS, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS y etc.. |

| Radio de curvatura | R=1D – 10D, 15D, 20D

|

| De | Pipe Cross, Equal Cross, Fitting Cross, Butt weld Cross |

| Los grados&Materiales | ASTM A403 WP316/316L, ASTM A403 WP304/304L, ASTM A182 F316L, 304l, DE 1.4301, DIN1.4306, DE 1.4401, DE 1.4404, 304h, 309, 310, 316, 316l, 317l, 321, 347, 904l,ASTM A234, ASME SA234 WPB , WPBW, ¿Por qué? 42, ¿Por qué? 46, ¿Por qué? 52, WPH 60, ¿Por qué? 65 & ¿Por qué? 70. ASME SA234 WP1 / WP5 / WP9 / WP11 / WP22 / WP91, ASTM A815, ASME SA815 UNS No S31803, S32205,S32750, S32950, ASTM B336, ASME SB336, Níquel 200 (SNU No. No2200), Níquel 201 (SNU No. N02201), Monel 400 (SNU No. N04400), Monel 500 (SNU No. N05500), Inconel 800 (SNU No. N08800), Inconel 825 (SNU No. N08825), Inconel 600 (SNU No. N06600), Inconel 625 (SNU No. N06625), Inconel 601 (SNU No. N06601), HastelloyC 276 (SNU No. N10276), Aleación 20 (SNU No. N08020), Titanio (Grado I & II), Cuproníquel 70/30, CuNi10Fe1Mn, CuNi30Mn1Fe.

|

| Tipo | Butt Weld (BW) / Sin costura / soldado / ACRE / fabricado |

| Coating / Tratamiento de superficies | Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

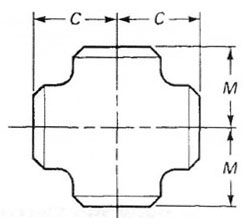

DIMENSIONS OF BUTTWELD EQUAL CROSS – ANSI 16.9

Stainless Steel Equal Cross Fitting Drawing

| Nominal Pipe Size (NPS) | DN | Outside Diameter at Bevel | Center- to-End | |

| Run.C | Outlet. M[Notes(1) y (2)] | |||

| 1/2 | 15 | 21.3 | 25 | 25 |

| 3/4 | 20 | 26.7 | 29 | 29 |

| 1 | 25 | 33.4 | 38 | 38 |

| 1-1/4 | 32 | 42.2 | 48 | 48 |

| 1-1/2 | 40 | 48.3 | 57 | 57 |

| 2 | 50 | 60.3 | 64 | 64 |

| 2-1/2 | 65 | 73.0 | 76 | 76 |

| 3 | 80 | 88.9 | 86 | 86 |

| 3-1/2 | 90 | 101.6 | 95 | 95 |

| 4 | 100 | 114.3 | 105 | 105 |

| 5 | 125 | 141.3 | 124 | 124 |

| 6 | 150 | 168.3 | 143 | 143 |

| 8 | 200 | 219.1 | 178 | 178 |

| 10 | 250 | 273.0 | 216 | 216 |

| 12 | 300 | 323.8 | 254 | 254 |

| 14 | 350 | 355.6 | 279 | 279 |

| 16 | 400 | 406.4 | 305 | 305 |

| 18 | 450 | 457 | 343 | 343 |

| 20 | 500 | 508 | 381 | 381 |

| 22 | 550 | 559 | 419 | 419 |

| 24 | 600 | 610 | 432 | 432 |

| 26 | 650 | 660 | 495 | 495 |

| 28 | 700 | 711 | 521 | 521 |

| 30 | 750 | 762 | 559 | 559 |

| 32 | 800 | 813 | 597 | 597 |

| 34 | 850 | 864 | 635 | 635 |

| 36 | 900 | 914 | 673 | 673 |

| 38 | 950 | 965 | 711 | 711 |

| 40 | 1000 | 1016 | 749 | 749 |

| 42 | 1050 | 1067 | 762 | 711 |

| 44 | 1100 | 1118 | 813 | 762 |

| 46 | 1150 | 1168 | 851 | 800 |

| 48 | 1200 | 1219 | 889 | 838 |

Dimensional Tolerances of Buttweld Equal Cross as per ASME B16.9

| Nominal Pipe Size | 1/2 to 2½ | 3 to 3½ | 4 | 5 a 8 |

| Diámetro exterior at Bevel (D) |

+ 1.6 – 0.8 |

1.6 | 1.6 | + 2.4 – 1.6 |

| Inside Diameter at End | 0.8 | 1.6 | 1.6 | 1.6 |

| Center to End LR (A/B) | 2 | 2 | 2 | 2 |

| Center to End 3D (A/B) | 3 | 3 | 3 | 3 |

| Nominal Pipe Size | 10 a 18 | 20 a 24 | 26 a 30 | 32 a 48 |

| Diámetro exterior at Bevel (D) |

+ 4 – 3.2 |

+ 6.4 – 4.8 |

+ 6.4 – 4.8 |

+ 6.4 – 4.8 |

| Inside Diameter at End | 3.2 | 4.8 | + 6.4 – 4.8 |

+ 6.4 – 4.8 |

| Center to End LR (A/B) | 2 | 2 | 3 | 5 |

| Center to End 3D (A/B) | 3 | 3 | 6 | 6 |

| Espesor de pared (t) | Not less than 87.5% of Nominal Wall Thickness | |||

ASME B16.9 Buttweld Equal Cross Weight Chart

| Nominal pipe size in | SCH 10 | SCH 20 | SCH 30 | SCH 40 | ||||||||

| wall thk mm | weight kg | weight kg | wall thk mm | weight kg | weight kg | wall thk mm | weight kg | weight kg | wall thk mm | weight kg | weight kg | |

| t | t | t | t | |||||||||

| 1/2″ | 2.77 | 0.21 | ||||||||||

| 3/4″ | 2.87 | 0.21 | ||||||||||

| 1″ | 3.38 | 0.34 | ||||||||||

| 1.1/4″ | 3.68 | 0.92 | ||||||||||

| 1.1/2″ | 3.56 | 0.63 | ||||||||||

| 2″ | 3.91 | 1.49 | ||||||||||

| 2.1/2″ | 5.16 | 2.68 | ||||||||||

| 3″ | 5.49 | 3.75 | ||||||||||

| 3.1/2″ | 5.74 | 5 | ||||||||||

| 4″ | 6.02 | 6.5 | ||||||||||

| 5″ | 6.55 | 10 | ||||||||||

| 6″ | 7.11 | 16 | ||||||||||

| 8″ | 6.35 | 23 | 7.04 | 24.6 | 8.18 | 27 | ||||||

| 10″ | 6.35 | 34.7 | 7.8 | 40 | 9.27 | 41 | ||||||

| 12″ | 6.35 | 43.4 | 8.38 | 56.6 | 10.31 | 70.5 | ||||||

| 14″ | 6.35 | 68 | 7.92 | 84 | 9.53 | 102 | 11.13 | 105 | ||||

| 16″ | 6.35 | 90.8 | 7.92 | 100 | 9.53 | 110 | 12.7 | 167 | ||||

| 18″ | 6.35 | 93.1 | 9.53 | 127 | 11.13 | 164 | 14.27 | 237.45 | ||||

| 20″ | 6.35 | 112 | 9.53 | 168 | 12.7 | 245 | 15.09 | 320 | ||||

| 22″ | 6.35 | 146 | 9.53 | 220 | 12.7 | 280 | ||||||

| 24″ | 6.35 | 160 | 12.7 | 240 | 14.27 | 373 | 17.48 | 570.65 | ||||

| 26″ | 7.92 | 293.28 | 12.7 | 360.2 | ||||||||

| 28″ | 7.92 | 280.98 | 12.7 | 421 | 15.88 | 526.25 | ||||||

| 30″ | 7.92 | 322.64 | 12.7 | 483.1 | 15.88 | 603.75 | ||||||

| 32″ | 7.92 | 375.23 | 12.7 | 559 | 15.88 | 698.75 | 17.48 | 768.6 | ||||

| 34″ | 7.92 | 482.72 | 12.7 | 644.1 | 15.88 | 805.13 | 17.48 | 885.65 | ||||

| 36″ | 7.92 | 488.3 | 12.7 | 730.3 | 15.88 | 912.88 | 19.05 | |||||

ASME B16.9 SS Equal Cross Angularity Tolerance

| Ángulo de salida máximo | Max fuera del avión | |

| q | PAG | |

| 1/2 a 4 | 1 | 2 |

| 5 a 8 | 2 | 4 |

| 10 a 12 | 3 | 5 |

| 14 a 16 | 3 | 7 |

| 18 a 24 | 4 | 10 |

| 26 a 30 | 5 | 10 |

| 32 a 42 | 5 | 13 |

| 44 a 48 | 5 | 20 |

Buttweld Equal Cross Manufacturing Standards

| Norma ASME | ASME/ANSI B16.9, ASME/ANSI B16.28, MSS-SP-43 |

| Estándar DIN | DIN28011, DIN2617, DIN2616, DIN2615, DIN2605 |

| Un estandar | EN10253-2, EN10253-1 |

| ASME B16.25 | Extremos para soldar a tope |

| ASME B16.9 | Soldadura a tope de accesorios forjados fabricados en fábrica |

| ASME B16.28 | Wrought Steel Equal Cross and Buttwelding Returns |

| ASTM A403 – ASME SA403 | Standard Specification for Wrought Austenitic SS Piping Fitting |

| MSS SP-43 | Forjado & Accesorio fabricado para soldar a tope para baja presión, Aplicaciones resistentes a la corrosión |

Buttweld Equal Cross Materials and Grades

| Stainless Steel Buttweld Equal Cross |

| ASTM A403 WP Gr. 304, 304l, 304h, 310, 316, 316l, 316h, 316De, 317l, 321, 347, 904l |

| Carbon Steel Buttweld Equal Cross |

| ASTM A234 WPB, WPBW, ¿Por qué? 70, ¿Por qué? 65, ¿Por qué? 60, ¿Por qué? 52, ¿Por qué? 46, & ¿Por qué? 42. |

| Low Temperature Buttweld Equal Cross |

| ASTM A420 WPL6, ASTM A420 WPL3 |

| Alloy Steel Buttweld Equal Cross |

| ASTM / ASME A/S.A 234 Gramo. WP1, WP5, WP9, WP11, WP12, WP22, WP91 |

| Dúplex & Super Duplex Steel Buttweld Equal Cross |

| ASTM A815, ASME SA815 UNS NO S31803, UNS NO S32205, EE. UU. S32750, UNS S32950. Numero de Material. 1.4462 |

| Nickel Alloy Buttweld Equal Cross |

| A NOSOTROS 10276 (HASTELLOY C 276), A NOSOTROS 6625 (INCONEL 625), A NOSOTROS 6601 (INCONEL 601), A NOSOTROS 6600 (INCONEL 600), A NOSOTROS 8825 (INCONEL 825), A NOSOTROS 8020 (ALLOY 20 / 20 CB 3), A NOSOTROS 4400 (MONEL 400), A NOSOTROS 2201 (NICKEL 201), ASTM / ASME SB 336 A NOSOTROS 2200 (NICKEL 200) |

Types of Equal Cross

| Equal Cross | ASME B16.9 Equal Cross |

| Equal Cross Pipe Fittings | ASME B16.28 Cross |

| Threaded Equal Cross | MSS-SP-43 Equal Cross |

| Seamless Cross | JIS B2313 Equal Cross |

| Buttweld Welded Equal Cross | JIS B2312 Cross |

| Buttweld Pipe Cross | Fabricated Pipe Cross |

| Forged Equal Cross | Seamless Equal Cross Fittings |

Buttweld Equal Cross Application

ASME B16.9 Equal Cross are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a broad range of Buttweld Pipe Cross through a worldwide network of stock-keeping branches. These Equal Pipe Cross is use in various industries like :

- Stainless Steel Buttweld Equal Cross uses in Oil and Gas Pipeline

- Butt weld Equal Cross uses in Chemical Industry

- Alloy Steel Equal Cross uses in Plumbing

- Buttweld Pipe Cross uses in Heating

- Buttweld Equal Cross Fittings uses in Water Supply Systems

- ANSI B16.9 Buttweld Equal Cross uses in Power Plant

- Buttweld Equal Cross Fitting uses in Paper & Industria de la celulosa

- Equal Cross uses in General Purpose Applications

- Buttweld Cross uses in Fabrication Industry

- Equal Cross uses in Food Processing Industry

- Buttweld Equal Cross uses in Structural Pipe

Proveedor de tubos de acero inoxidable Wenzhou Kaixin China

Proveedor de tubos de acero inoxidable Wenzhou Kaixin China