Stainless steel lap joint stub end is a type of fitting used in piping systems. It is designed to be used with a lap joint flange in order to connect two sections of pipe.

The stub end is made from stainless steel, which is a highly durable and corrosion-resistant material that is commonly used in a wide range of industrial applications. The lap joint design allows for easy alignment and installation, while the stub end itself is designed to provide a secure and leak-proof seal.

Stainless steel lap joint stub ends are available in a range of sizes and thicknesses to accommodate a variety of piping systems. They are commonly used in high-pressure and high-temperature applications, as well as in corrosive environments where resistance to corrosion is essential.

En general, stainless steel lap joint stub ends are a highly versatile and reliable pipe fitting that can be used in a wide range of industrial applications.

Lap Joint Stub End Specification

| Tallas | 1/2“A 36”, (Sin costuras hasta 24”), (Soldado de 8” A 36”) |

| Estándares | ANSI/ASME :ASTM A403 / ASME SA403, ANSI B16.9, ASME B16.25, ASME B16.28, MSS SP-43.DIN : DIN2605, DIN2615, DIN2616, DIN2617, DIN28011,EN : EN10253-1, EN10253-2 |

| Dimensiones | MSS SP-75, ANSI B16.28, MSS-SP-43 Tipo A, MSS-SP-43 Tipo B, BS1640, EN 10253 – 4, DE 2605, JIS B2312, ANSI B16.9, JIS B2313 |

| Espesor | Horario 5S, 10S, 20S, T10, S20, S30, ETS, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS y etc.. |

| Radio de curvatura | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom. |

| De | Lap Joint Stub Ends, Extremos de trozos de tubería, Butt weld Lap Joint Stub Ends. |

| Los grados&Materiales | ASTM A403 WP316/316L, ASTM A403SA / A 774 WP-S, WP-W, WP-WX 304/304L, ASTM A182 F316L, 304l, DE 1.4301, DIN1.4306, DE 1.4401, DE 1.4404,ASTM A 815, ASME SA 815 Nº UNS S31803, S32205. EE. UU. S32750, S32950. Numero de Material. 1.4462,ASTM A234, ASME SA234 WPB , WPBW, ¿Por qué? 42, ¿Por qué? 46, ¿Por qué? 52, WPH 60, ¿Por qué? 65 & WPHY 70.ASTM A420 WPL3, A420 WPL6,ASTM / ASME A/S.A 234 Gramo. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91,ASTM B336, ASME SB336, Níquel 200 (SNU No. No2200), Níquel 201 (SNU No. N02201), Monel 400 (SNU No. N04400), Monel 500 (SNU No. N05500), Inconel 800 (SNU No. N08800), Inconel 825 (SNU No. N08825), Inconel 600 (SNU No. N06600), Inconel 625 (SNU No. N06625), Inconel 601 (SNU No. N06601), HastelloyC 276 (SNU No. N10276), Aleación 20 (SNU No. N08020), Titanio (Grado I & II), Cuproníquel 70/30, CuNi10Fe1Mn, CuNi30Mn1Fe. |

| Tipo | Butt Weld (BW), Sin costura (SMLS) soldado |

| Recubrimientos superficiales | Recubierto de epoxi, Pintado de negro, barnizado, Conexión.galvanizada |

| Tipo de conección | Campana final / Extremo roscado/abrazadera / Soldar/ Brida/ |

Buttweld Lap Joint Stub End Materials and Grades

| Stainless Steel Buttweld Lap Joint Stub End | ASTM A403 WP316/316L, ASTM A403SA / A 774 WP-S, WP-W, WP-WX 304/304L, ASTM A182 F316L, 304l, DE 1.4301, DIN1.4306, DE 1.4401, DE 1.4404 |

| Dúplex & Super Duplex Steel Buttweld Lap Joint Stub End | ASTM A 815, ASME SA 815 Nº UNS S31803, S32205. EE. UU. S32750, S32950. Numero de Material. 1.4462 |

| Carbon Steel Buttweld Lap Joint Stub End | ASTM A234, ASME SA234 WPB , WPBW, ¿Por qué? 42, ¿Por qué? 46, ¿Por qué? 52, WPH 60, ¿Por qué? 65 & ¿Por qué? 70. |

| Low Temperature Carbon Steel Buttweld Lap Joint Stub End | ASTM A420 WPL3, A420 WPL6 |

| Alloy Steel Buttweld Lap Joint Stub End | ASTM / ASME A/S.A 234 Gramo. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

| Nickel Alloy Buttweld Lap Joint Stub End | ASTM B336, ASME SB336, Níquel 200 (SNU No. No2200), Níquel 201 (SNU No. N02201), Monel 400 (SNU No. N04400), Monel 500 (SNU No. N05500), Inconel 800 (SNU No. N08800), Inconel 825 (SNU No. N08825), Inconel 600 (SNU No. N06600), Inconel 625 (SNU No. N06625), Inconel 601 (SNU No. N06601), HastelloyC 276 (SNU No. N10276), Aleación 20 (SNU No. N08020), Titanio (Grado I & II), Cuproníquel 70/30, CuNi10Fe1Mn, CuNi30Mn1Fe. |

Buttweld Lap Joint Stub End Manufacturing Standards

| Norma ASME | ASME/ANSI B16.9, ASME/ANSI B16.28, MSS-SP-43 |

| Estándar DIN | DIN28011, DIN2617, DIN2616, DIN2615, DIN2605 |

| Un estandar | EN10253-2, EN10253-1 |

| ASME B16.25 | Extremos para soldar a tope |

| ASME B16.9 | Soldadura a tope de accesorios forjados fabricados en fábrica |

| ASME B16.28 | Reductor excéntrico de acero forjado |

| ASTM A403 – ASME SA403 | Especificación estándar para accesorios de tubería de acero inoxidable austenítico forjado |

| MSS SP-43 | Forjado & Accesorio fabricado para soldar a tope para baja presión, Aplicaciones resistentes a la corrosión |

ASME B16.9 Butt Weld Lap Joint Stub End Dimensions

Dimensions are in millimeters unless otherwise indicated. Wall thickness (t) should be nominative by client. Outlet dimension (M) for NPS twenty-six and bigger is usually recommended however not needed.

| Nominal Bore | Diámetro exterior | Longitud F | Diameter of Lap | Radius of Fillet | ||||||||

| F (ANSI B16.9) | F (MSS SP-43) | GRAMO | R (ANSI B16.9) A (MSS SP-43) | B (MSS SP-43) | ||||||||

| milímetros | pulgadas | milímetros | pulgadas | milímetros | pulgadas | milímetros | pulgadas | milímetros | pulgadas | milímetros | pulgadas | |

| 1/2″ | 21.34 | 0.84 | 76.20 | 3.00 | 50.80 | 2.00 | 35.05 | 1.38 | 3.04 | 0.12 | 0.76 | 0.03 |

| 3/4″ | 26.67 | 1.05 | 76.20 | 3.00 | 50.80 | 2.00 | 42.93 | 1.69 | 3.04 | 0.12 | 0.76 | 0.03 |

| 1″ | 33.53 | 1.32 | 101.60 | 4.00 | 50.80 | 2.00 | 50.80 | 2.00 | 3.04 | 0.12 | 0.76 | 0.03 |

| 11/4″ | 42.16 | 1.66 | 101.60 | 4.00 | 50.80 | 2.00 | 63.50 | 2.50 | 4.83 | 0.19 | 0.76 | 0.03 |

| 11/2″ | 48.26 | 1.90 | 101.60 | 4.00 | 50.80 | 2.00 | 73.15 | 2.88 | 6.85 | 0.27 | 0.76 | 0.03 |

| 2″ | 60.45 | 2.38 | 152.40 | 6.00 | 63.50 | 2.50 | 91.95 | 3.62 | 7.87 | 0.31 | 0.76 | 0.03 |

| 21/2″ | 73.15 | 2.88 | 152.40 | 6.00 | 63.50 | 2.50 | 104.65 | 4.12 | 7.87 | 0.31 | 0.76 | 0.03 |

| 3″ | 88.90 | 3.50 | 152.40 | 6.00 | 63.50 | 2.50 | 127.00 | 5.00 | 9.65 | 0.38 | 0.76 | 0.03 |

| 31/2″ | 101.60 | 4.00 | 152.40 | 6.00 | 76.20 | 3.00 | 139.00 | 5.47 | 9.65 | 0.38 | 0.76 | 0.03 |

| 4″ | 114.30 | 4.50 | 152.40 | 6.00 | 76.20 | 3.00 | 157.00 | 6.18 | 11.17 | 0.44 | 0.76 | 0.03 |

| 5″ | 141.22 | 5.56 | 203.30 | 8.00 | 76.20 | 3.00 | 185.67 | 7.31 | 11.17 | 0.44 | 1.52 | 0.06 |

| 6″ | 168.15 | 6.62 | 203.20 | 8.00 | 88.90 | 3.50 | 215.90 | 8.50 | 12.70 | 0.50 | 1.52 | 0.06 |

| 8″ | 218.95 | 8.62 | 203.20 | 8.00 | 101.60 | 4.00 | 269.75 | 10.62 | 12.70 | 0.50 | 1.52 | 0.06 |

| 10″ | 273.05 | 10.75 | 254.00 | 10.00 | 127.00 | 5.00 | 323.85 | 12.75 | 12.70 | 0.50 | 1.52 | 0.06 |

| 12″ | 323.85 | 12.75 | 254.00 | 10.00 | 152.40 | 6.00 | 381.00 | 15.00 | 12.70 | 0.50 | 1.52 | 0.06 |

| 14″ | 355.60 | 14.00 | 304.80 | 12.00 | 152.40 | 6.00 | 412.75 | 16.25 | 12.70 | 0.50 | 1.52 | 0.06 |

| 16″ | 406.40 | 16.00 | 304.80 | 12.00 | 152.40 | 6.00 | 469.90 | 18.50 | 12.70 | 0.50 | 1.52 | 0.06 |

| 18″ | 457.20 | 18.00 | 304.80 | 12.00 | 152.40 | 6.00 | 533.40 | 21.00 | 12.70 | 0.50 | 1.52 | 0.06 |

| 20″ | 508.00 | 20.00 | 304.80 | 12.00 | 152.40 | 6.00 | 584.20 | 23.00 | 12.70 | 0.50 | 1.52 | 0.06 |

| 24″ | 609.60 | 24.00 | 304.80 | 12.00 | 152.40 | 6.00 | 692.15 | 27.25 | 12.70 | 0.50 | 1.52 | 0.06 |

Lap Joint Stub End Dimensional Tolerance

MSS SP-43 solely covers stainless steel butt weld fittings created to be used with Schedule 5S and 10S Lap Joint Stub End appropriate to be used with Schedule 40S pipe, como se describe en ASME B36.19. Las tolerancias de escala y dimensiones descritas en la unidad de área MSS SP-43 son considerablemente similares a las de las especificaciones ASME B16.9 de NPS. 1/2 — NPS twenty-four. Excepto en relación con el diámetro de la piel en el bisel..

| Lap Joint Stub Ends | ||

| SOBREDOSIS. de la vuelta G | Radio de filete de vuelta – R | Longitud total. –F |

| +0 -1 | +0-1 | 2 |

| +0 -1 | +0-1 | 2 |

| +0 -1 | +0 -2 | 2 |

| +0-1 | +0 -2 | 2 |

| +0 -1 | +0 -2 | 2 |

| +0 -2 | +0 -2 | 2 |

| +0 -2 | +0-2 | 3 |

| +0 -2 | +0 -2 | 3 |

Buttweld Lap Joint Stub End Weight Chart

| NPS

pulgadas |

EXTREMOS DEL MUNDO | |||

| Sch.

5S |

Sch.

10S |

Sch.

40S |

Sch.

80S |

|

| 1/2 | 0.06 | 0.08 | 0.12 | 0.13 |

| 3/4 | 0.07 | 0.09 | 0.15 | 0.17 |

| 1 | 0.09 | 0.15 | 0.20 | 0.25 |

| 1 1/4 | 0.13 | 0.20 | 0.30 | 0.35 |

| 1 1/2 | 0.16 | 0.25 | 0.38 | 0.46 |

| 2 | 0.25 | 0.40 | 0.55 | 0.75 |

| 2 1/2 | 0.35 | 0.50 | 0.80 | 1.00 |

| 3 | 0.50 | 0.60 | 1.10 | 1.50 |

| 4 | 0.70 | 1.00 | 1.80 | 2.50 |

| 5 | 1.00 | 1.25 | 2.50 | 3.50 |

| 6 | 1.60 | 1.95 | 3.70 | 5.50 |

| 8 | 2.50 | 3.10 | 5.90 | 10.0 |

| 10 | 4.00 | 4.90 | 10.5 | 14.0 |

| 12 | 6.60 | 7.10 | 15.0 | 20.0 |

| 14 | 6.40 | 7.80 | 15.5 | 20.5 |

| 16 | 7.90 | 9.00 | 18.0 | 24.0 |

| 18 | 9.30 | 10.5 | 21.0 | 28.0 |

| 20 | 12.0 | 13.5 | 23.5 | 31.0 |

| 24 | 16.5 | 19.0 | 28.5 | 38.0 |

| Pesos aproximados en kg, densidad 8 kg/dm3 | ||||

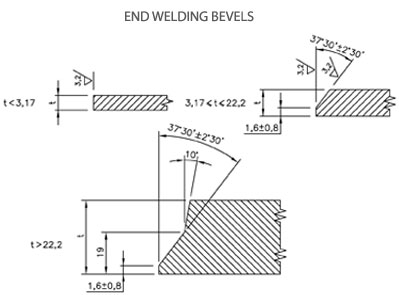

End welding bevels of Stub Ends

Stainless Steel Lap Joint Stub End Beveled Drawing

| NOMINAL PIPE SIZE (Inches) | NÓTESE BIEN | OD | THICKNESS | SCH 10 | SCH 20 | SCH 30 | SCH 40 | SCH 80 |

| 1/2 | 15NÓTESE BIEN | 21.30 | 1.65 | 2.11 | __ | 2.41 | 2.77 | 3.73 |

| 3/4 | 20NÓTESE BIEN | 26.70 | 1.65 | 2.11 | __ | 2.41 | 2.87 | 3.91 |

| 1 | 25NÓTESE BIEN | 33.40 | 1.65 | 2.77 | __ | 2.90 | 3.38 | 4.55 |

| 1 1/4 | 32NÓTESE BIEN | 42.20 | 1.65 | 2.77 | __ | 2.97 | 3.56 | 4.85 |

| 1 1/2 | 40NÓTESE BIEN | 48.30 | 1.65 | 2.77 | __ | 3.18 | 3.68 | 5.08 |

| 2 | 50NÓTESE BIEN | 60.30 | 1.65 | 2.77 | __ | 3.18 | 3.91 | 5.54 |

| 2 1/2 | 65NÓTESE BIEN | 73.00 | 2.11 | 3.05 | __ | 4.78 | 5.16 | 7.01 |

| 3 | 80NÓTESE BIEN | 88.90 | 2.11 | 3.05 | __ | 4.78 | 5.49 | 7.62 |

| 3 1/2 | 90NÓTESE BIEN | 101.60 | 2.11 | 3.05 | __ | 4.78 | 5.74 | 8.08 |

| 4 | 100NÓTESE BIEN | 114.30 | 2.11 | 3.05 | __ | 4.78 | 6.02 | 8.56 |

| 5 | 125NÓTESE BIEN | 141.30 | 2.77 | 3.40 | __ | __ | 6.55 | 9.53 |

| 6 | 150NÓTESE BIEN | 168.30 | 2.77 | 3.40 | __ | __ | 7.11 | 10.97 |

| 8 | 200NÓTESE BIEN | 219.10 | 2.77 | 3.76 | 6.35 | 7.04 | 8.18 | 12.70 |

| 10 | 250NÓTESE BIEN | 273.00 | 3.40 | 4.19 | 6.35 | 7.80 | 9.27 | 15.09 |

| 12 | 300NÓTESE BIEN | 323.80 | 3.96 | 4.57 | 6.35 | 8.38 | 10.31 | 17.48 |

| 14 | 350NÓTESE BIEN | 355.60 | 3.96 | 6.35 | 7.92 | 9.53 | 11.13 | 19.05 |

| 16 | 400NÓTESE BIEN | 406.40 | 4.19 | 6.35 | 7.92 | 9.53 | 12.7 | 21.44 |

| 18 | 450NÓTESE BIEN | 457.00 | 4.19 | 6.35 | 7.92 | 11.13 | 14.27 | 23.83 |

| 20 | 500NÓTESE BIEN | 508.00 | 4.78 | 6.35 | 9.53 | 12.70 | 15.09 | 26.19 |

| 22 | 550NÓTESE BIEN | 559.00 | 4.78 | 6.35 | 9.53 | 12.70 | __ | 28.58 |

| 24 | 600NÓTESE BIEN | 610.00 | 5.54 | 6.35 | 9.53 | 14.27 | 17.48 | 30.96 |

SS Lap Joint Stub End Angularity Tolerance

| DAKOTA DEL NORTE | Ángulo de salida máximo | Max fuera del avión |

| q | PAG | |

| 1/2 a 4 | 1 | 2 |

| 5 a 8 | 2 | 4 |

| 10 a 12 | 3 | 5 |

| 14 a 16 | 3 | 7 |

| 18 a 24 | 4 | 10 |

| 26 a 30 | 5 | 10 |

| 32 a 42 | 5 | 13 |

| 44 a 48 | 5 | 20 |

Lap Joint Stub End Types

Lap Joint Stub end are offered in three different ways, type A, B y C. Los extremos tipo A y B son similares a los accesorios forjados., como codos y tees, y el extremo tipo C se fabrican en tamaños personalizados.

Escribe un

The Type A lap joint Stub end is employed for standard joint flange. El espesor del traslapo en el extremo del trozo es mayor o igual al espesor nominal de la pared de la tubería.. Además, the outer corner radius of the sort A will receive the lap joint flange. La esquina interior es cuadrada.. El regazo a veces incluye una cara rugosa mecanizada..

Tipo B

The Type B lap joint Stub end is employed for standard slip on flanges as lap flanges. El espesor del traslapo en estos extremos cortos es mayor o igual al espesor nominal de la pared de la tubería.. También, El radio de la esquina exterior del tipo B es lo suficientemente pequeño como para recibir la brida deslizante que se utilizará como brida de respaldo.. La esquina interior es cuadrada.. El regazo a veces incluye una cara rugosa mecanizada..

Tipo C

The Type C lap joint Stub end will be used for standard lap joint flange, y ponerle brida. Tiene un borde redondeado en el diámetro interior del regazo.. Si necesario, el radio se creará cerrado a un cuadrado. El espesor del traslapo es 75° de la pared del tubo.. El tipo C es lo suficientemente corto para acomodar cualquier brida de respaldo.. The lap joint on kind C is smooth, y no está mecanizado.

ASME B16.9 Buttweld Lap Joint Stub End Available Types

| Buttweld Lap Joint Stub End | Butt Weld Lap Joint Stub Ends |

| ASME B16.9 Butt weld Lap Joint Stub End | Steel Lap Joint Stub Ends Fittings |

| Stainless Steel Lap Joint Stub End Suppliers | SS Buttweld Lap Joint Stub Ends Fitting |

| ANSI B16.9 Buttweld Lap Joint Stub End Dealer | ASME B16.28 Buttweld Lap Joint Stub Ends Exporter |

| Welded Butt weld Lap Joint Stub Ends Stockholder | Seamless Butt weld Lap Joint Stub End Distributors |

| Carbon Steel Lap Joint Stub End | High Quality Lap Joint Stub End Manufacturer |

| ASTM A403 Stainless Steel Lap Joint Stub Ends | Duplex Steel Buttweld Lap Joint Stub End |

| Super Duplex Steel Buttweld Lap Joint Stub End | Copper Nickel Lap Joint Stub End |

| High Nickel Alloy Lap Joint Stub Ends | Hastelloy Lap Joint Stub Ends Stockist |

| Titanium Buttweld Lap Joint Stub End | Inconel Butt weld Lap Joint Stub End |

Buttweld Lap Joint Stub End Application

ASME B16.9 Lap Joint Stub End are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a broad range of Buttweld Lap Joint Stub Ends through a worldwide network of stock-keeping branches. These Lap Joint Stub Ends is use in various industries like :

- Stainless Steel Buttweld Lap Joint Stub End uses in Oil and Gas Pipeline

- Butt weld Lap Joint Stub Ends uses in Chemical Industry

- Alloy Steel Lap Joint Stub Ends uses in Plumbing

- Buttweld Lap Joint Stub Ends uses in Heating

- Buttweld Lap Joint Stub End Fittings uses in Water Supply Systems

- ANSI B16.9 Buttweld Lap Joint Stub Ends uses in Power Plant

- Buttweld Lap Joint Stub End Fitting uses in Paper & Industria de la celulosa

- Lap Joint Stub End uses in General Purpose Applications

- Buttweld Lap Joint Stub End uses in Fabrication Industry

- Lap Joint Stub End uses in Food Processing Industry

- Buttweld Lap Joint Stub Ends uses in Structural Pipe

Proveedor de tubos de acero inoxidable Wenzhou Kaixin China

Proveedor de tubos de acero inoxidable Wenzhou Kaixin China