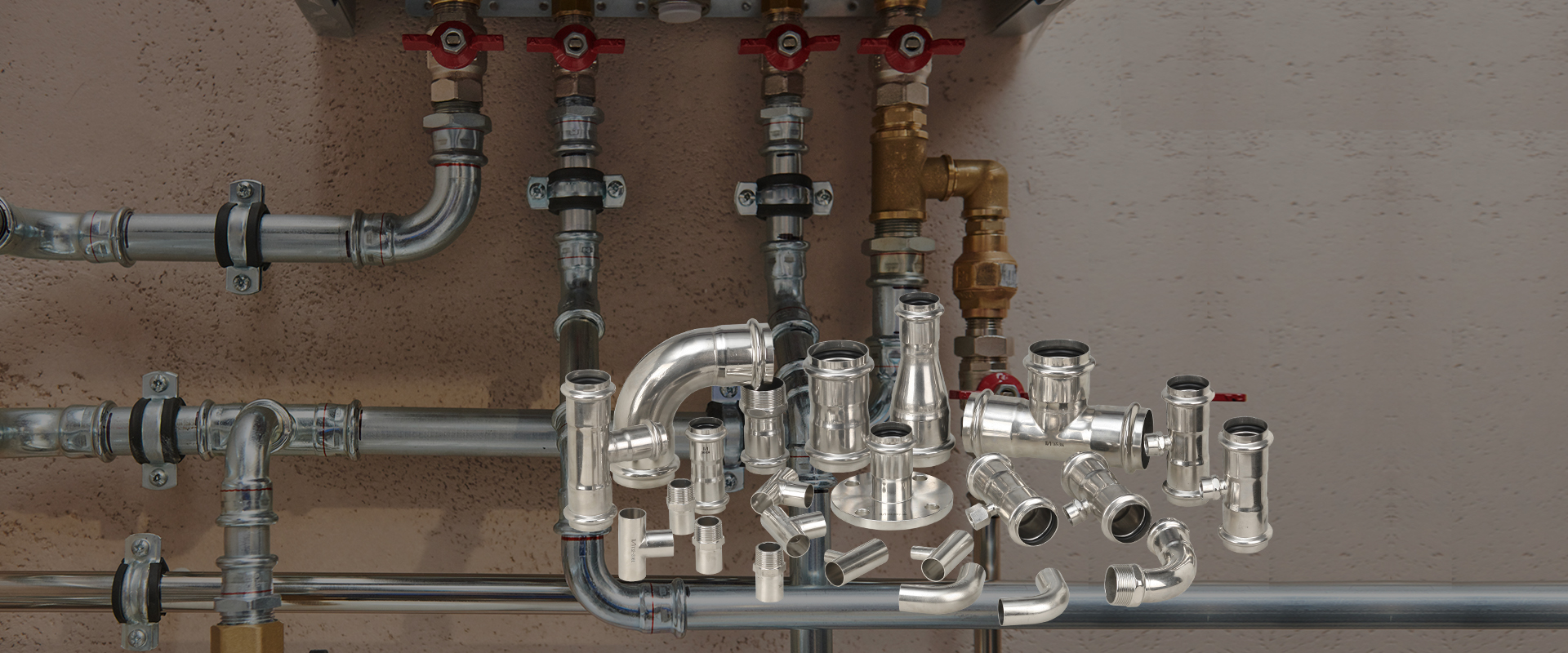

What is stainless steel pipe connection?

Using the effective rigidity of metal materials and the elastic compression ratio of sealing materials, and taking full advantage of the length of the socket, the connection method of radial crimping with clamps (or dies, jaws) on both sides of the U-shaped groove of the socket of pipe fittings is called double crimping.

Double clamping principle

Due to the full use of the effective rigidity of metal materials, the two ends of the pipe and pipe fittings are crimped with calipers at the joint to realize the face-fixing, compression into two hexagonal shapes, and comprehensive anti-lock, thus greatly improving its anti-pulling ability and anti-rotation energy. The double-clamp type pipeline adopts the advanced compression ratio principle of the O-ring seal. After the O-ring in the U-shaped groove is compressed, it gives play to its long-term elasticity, thus achieving the purpose of permanent sealing. In addition, the double-clamp pressure can effectively prevent the risk of water leakage when the pipe is not inserted to the bottom during construction due to the advantages of the socket.

Advantages of double-clamp connection

1. Uplift resistance principle: small mouth and large inside, with uplift resistance > 3.0 MPa;

Anti-rotation principle: press into hexagonal shape to prevent water leakage during rotation;

Leakage sealing principle: implement the leakage sealing of the national standard O-ring seal, not the leakage sealing;

Reliable: good seismic resistance, excellent pull-out performance, suitable for concealment, maintenance-free and long life;

Economical: Mainly using cold rolled coil material, with good density and low price.

2. Simple and fast installation: simple installation without maintenance; The installation of single pipe fittings is calculated in seconds, which is convenient and fast.

3. Avoid human factors: the installation quality is controlled by equipment to avoid the influence of human emotions, and there is no need for high-tech installation workers.

4. The installation equipment is light, does not require a lot of manpower, and saves resources.

5. The operating radius is small, and no large operating environment is required.

6. It Suitable for special environment: installation in special fields such as pipe well, ceiling, trench, jne.

7. High connection strength, good anti-seismic performance, excellent pull-out performance, suitable for concealment, enhanced anti-rotation principle, preventing rotation leakage in use, maintenance-free and long service life.

8. The safety and reliability of the socket are enhanced, and the installation is simple without maintenance.

9. Semi-flexibility: meet a little bending and expansion.

10. The anti-mechanical external force damage, anti-twist and anti-pulling performance of the double-clamp connection is more excellent and reasonable

11. And Compared with traditional products, the double-clamp water supply pipeline system is healthier, more advanced, more economical, more durable and more robust, and has five water-tight characteristics, such as “bending 30 degrees of joint looseness and no leakage”, “strong vibration and no leakage”, “flattening 70-80% of water leakage”, “rotating 360 degrees of water leakage”, ja “pulling displacement and no leakage at the connection to a certain extent”, It is one of the safest and most reliable thin-walled stainless steel pipeline systems in China

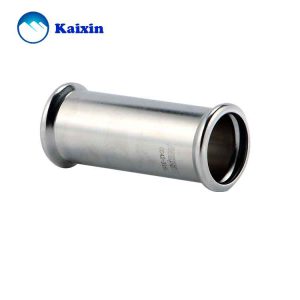

Ruostumattomasta teräksestä valmistettujen putkien toimittaja Wenzhou Kaixin Kiinassa

Ruostumattomasta teräksestä valmistettujen putkien toimittaja Wenzhou Kaixin Kiinassa