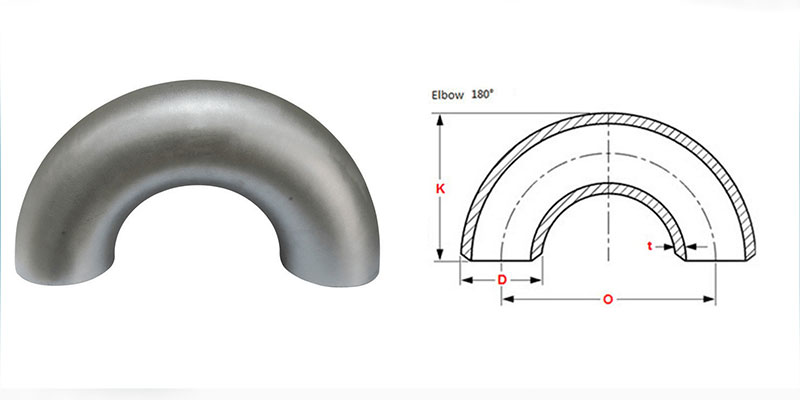

An elbow is the pipe fittings that are used extensively as a form of connections in between two lengths of pipes for the purpose of producing the change into the flow direction into the pipe, at the angle of 180 degré, 90 deg or 45 degré. Elbow pipe fitting is also called as the bend that is available in the ranges of materials including alloy steel, acier au carbone, acier inoxydable, nickel alloy, super duplex, duplex, and cupro-nickel, etc.. 180° Long Radius Elbow is also termed as the return bend that permits the complete reversal of the flow. The distance in between the center line and end of the elbow is 3 x NPS.

Some qualities of it are High mechanical strength rugged construction, Smoothness in surface finishes, Perfect dimensional accuracy, Anti-corrosive body, and Pitting and oxidation resistance.

180 DEGREE LONG RADIUS ELBOW SPECIFICATIONS

| Diamètre extérieur (DE) | Seamless 180° Long Radius Elbow (1/2″~24″), ACRE / Fabricated Elbow / Soudé (1/2″~48″) |

| Normes | ANSI – B 16.9,ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’API 590-605,ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings”,ASME B16.25 – ‘Buttwelding Ends’,ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’,MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Dimensions | ASME/ANSI B16.9, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JISB2313, ASME B16.28 |

| Calendrier | Schedule 5S, 10S, 20S, S10, S20, S30, MST, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS et etc.. |

| Bending Radius | R=1D – 10D, 15D, 20D |

| Depuis | 180° Long Radius Elbow, Butt weld 180° Long Radius Elbow. |

| Matériels | 304/L/H/LN, 316/L/H/LN/Ti, 321/H, 317/L/LN, 347/H, 310S/H, N08904(904L), S31803,S32205, S32750, S32760, N02200, N02201, N04400, N06600, N06690, N06625, N06985(G3), N08028, N08800, N08810, N08811, N08825Surface,Monel, Nickel, Inconel, Hastalloy, Titane, Tantale, Acier inoxydable, Acier allié, Acier au carbone, Cupro-Nickel 90/10 & 70/30, Acier inoxydable ASME / ASTM SA / A403 SA / UN 774 WP-S, WP-W, WP-WX, DEPUIS 1.4301, DIN1.4306, DEPUIS 1.4401, DEPUIS 1.4404 |

| Taper | Soudure bout à bout (PC) / Soudé / ACRE / Fabriqué |

| SS Melting Points | 1400-1450°C (WP304, WP304L), 1390-1440 °C (WP316L), 1370 – 1400 °C (WP316) |

180 DEGREE LONG RADIUS ELBOW – MATERIALS & NOTES

| Soudure bout à bout en acier inoxydable 180 Coude à long rayon en degrés | ASTM A403 WP316/316L, ASTM A403 SA / UN 774 WP-S, WP-W, WP-WX 304/304L, ASTM A182 F316L, 304L, DEPUIS 1.4301, DIN1.4306, DEPUIS 1.4401, DEPUIS 1.4404 |

| Duplex & Soudure bout à bout en acier super duplex 180 Coude à long rayon en degrés | ASTMA 815, ASME SA 815 NOUS NON S31803, S32205. États-Unis S32750, S32950. Numéro de matériau. 1.4462 |

| Soudure bout à bout en acier au carbone 180 Coude à long rayon en degrés | ASTMA234, ASME SA234 WPB , WPBW, POURQUOI 42, POURQUOI 46, POURQUOI 52, WPH 60, POURQUOI 65 & POURQUOI 70. |

| Acier au carbone basse température 180 Coude à long rayon en degrés | ASTM A420 WPL3, A420 WPL6 |

| Soudure bout à bout en acier allié 180 Coude à long rayon en degrés | ASTM / ASME A/SA 234 Gr.. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

| Soudure bout à bout en alliage de nickel 180 Coude à long rayon en degrés | ASTMB336, ASME SB336, Nickel 200 (États-Unis Non. N°2200), Nickel 201 (États-Unis Non. N02201), Monel 400 (États-Unis Non. N04400), Monel 500 (États-Unis Non. N05500), Inconel 800 (États-Unis Non. N08800), Inconel 825 (États-Unis Non. N08825), Inconel 600 (États-Unis Non. N06600), Inconel 625 (États-Unis Non. N06625), Inconel 601 (États-Unis Non. N06601), Hastelloy C 276 (États-Unis Non. N10276), Alliage 20 (États-Unis Non. N08020), Titane (Première année & II), Cupro-Nickel 70/30, CuNi10Fe1Mn, CuNi30Mn1Fe. |

Soudé bout à bout 180 Deg Long Radius Elbows Application Industries

- Petrochemical Industry

- Chemical Industry

- Oil and Gas Industry

- Pulpe & Paper Indusry

- Power Plant Industry

- Food Processing Industry

- Pharmaceuticals Industry

- Energy Industry

- Aerospace Industry

DIMENSIONS DE 180 DEGREE LONG RADIUS ELBOW – ANSI 16.9

ASME B16.9 Buttweld 180° Short Radius Elbow Dimensions Drawing

| Nominal pipe size | Diamètre extérieur

en biseau |

Center to Center | Back to Faces | ||||

| 180° Return | |||||||

| P. | K | ||||||

| DN | INCH | Series A | Series B | LR | LR | ||

| 15 | 1/2 | 21.3 | 18 | 76 | 48 | ||

| 20 | /4 | 26.9 | 25 | 76 | 51 | ||

| 25 | 1 | 33.7 | 32 | 76 | 56 | ||

| 32 | 11/4 | 42.4 | 38 | 95 | 70 | ||

| 40 | 11/2 | 48.3 | 45 | 114 | 83 | ||

| 50 | 2 | 60.3 | 57 | 152 | 106 | ||

| 65 | 21/2 | 76.1(73) | 76 | 191 | 132 | ||

| 80 | 3 | 88.9 | 89 | 229 | 159 | ||

| 90 | 31/2 | 101.6 | – | 267 | 184 | ||

| 100 | 4 | 114.3 | 108 | 305 | 210 | ||

| 125 | 5 | 139.7 | 133 | 381 | 262 | ||

| 150 | 6 | 168.3 | 159 | 457 | 313 | ||

| 200 | 8 | 219.1 | 219 | 610 | 414 | ||

| 250 | 10 | 273.0 | 273 | 762 | 518 | ||

| 300 | 12 | 323.9 | 325 | 914 | 619 | ||

| 350 | 14 | 355.6 | 377 | 1067 | 711 | ||

| 400 | 16 | 406.4 | 426 | 1219 | 813 | ||

| 450 | 18 | 457.2 | 478 | 1372 | 914 | ||

| 500 | 20 | 508.0 | 529 | 1524 | 1016 | ||

| 550 | 22 | 559 | – | · 180 Degree Elbows – It is used when change in the direction of pipe required is 180°

· L/R – Long radius |

|||

| 600 | 24 | 610 | 630 | ||||

| 650 | 26 | 660 | – | ||||

| 700 | 28 | 711 | 720 | ||||

| 750 | 30 | 762 | – | ||||

| 800 | 32 | 813 | 820 | ||||

| 850 | 34 | 864 | – | ||||

| 900 | 36 | 914 | 920 | ||||

| 950 | 38 | 965 | – | ||||

| 1000 | 40 | 1016 | 1020 | ||||

| 1050 | 42 | 1067 | – | ||||

| 1100 | 44 | 1118 | 1120 | ||||

| 1150 | 46 | 1168 | – | ||||

| 1200 | 48 | 1220 | 1220 | ||||

TOLÉRANCES DIMENSIONNELLES DE 180 DEGREE LONG RADIUS ELBOW – ASME B16.9

| For all Pipe Fittings | 180° Retours | |||||

| Taille nominale du tuyau (NPS) | Épaisseur de paroi

t / t1 |

Ø extérieur

en biseau |

Ø intérieur

à la fin |

Retour à Face Dim.

K |

Dim centre à centre.

Ô |

Aligner- ment des fins

U |

| 1/2 un 2 1/2 | Pas | 1 | 0,8 | 7 | 7 | 1 |

| 3 un 3 1/2 | moins | 1 | 1,6 | 7 | 7 | 1 |

| 4 | que | +2 -1 | 1,6 | 7 | 7 | 1 |

| 5 un 6 | 87,50% | +3 -1 | 1,6 | 7 | 7 | 1 |

| 8 | de nominal | 2 | 1,6 | 7 | 7 | 1 |

| 10 | épaisseur | +4 -3 | 3,2 | 7 | 7 | 2 |

| 12 un 18 | 3,2 | +4 -3 | 7 | 10 | 2 | |

| 20 un 24 | 4,8 | +6 -5 | 7 | 10 | 2 | |

| 26 un 30 | 4,8 | +7 -5 | ….. | ….. | ….. | |

| 32 un 48 | 4,8 | +7 -5 | ….. | ….. | ….. | |

ASME B16.9 180° Long Radius Elbow Angularity Tolerance

| ND | Angle de sortie maximum | Max hors avion |

| Q | P. | |

| 1/2 un 4 | 1 | 2 |

| 5 un 8 | 2 | 4 |

| 10 un 12 | 3 | 5 |

| 14 un 16 | 3 | 7 |

| 18 un 24 | 4 | 10 |

| 26 un 30 | 5 | 10 |

| 32 un 42 | 5 | 13 |

| 44 un 48 | 5 | 20 |

WEIGHT CHART OF 180° DEGREE LONG RADIUS ELBOW

| NPS

pouces |

ELBOWS LR 180° | |||

| Sch.

5S |

Sch.

10S |

Sch.

40S |

Sch.

80S |

|

| 1/2 | 0.05 | 0.06 | 0.08 | 0.10 |

| 3/4 | 0.06 | 0.07 | 0.09 | 0.11 |

| 1 | 0.09 | 0.15 | 0.18 | 0.20 |

| 1 1/4 | 0.13 | 0.20 | 0.25 | 0.35 |

| 1 1/2 | 0.18 | 0.30 | 0.40 | 0.50 |

| 2 | 0.30 | 0.50 | 0.70 | 0.90 |

| 2 1/2 | 0.60 | 0.85 | 1.35 | 1.80 |

| 3 | 0.90 | 1.30 | 2.00 | 2.90 |

| 4 | 1.40 | 2.00 | 4.00 | 5.90 |

| 5 | 2.90 | 3.60 | 6.50 | 9.70 |

| 6 | 4.00 | 5.00 | 10.5 | 16.0 |

| 8 | 7.40 | 10.0 | 21.5 | 33.5 |

| 10 | 13.6 | 16.8 | 38.5 | 52.5 |

| 12 | 23.4 | 27.0 | 59.0 | 79.0 |

| 14 | 29.0 | 35.0 | 70.0 | 94.0 |

| 16 | 41.3 | 47.0 | 95.0 | 125 |

| 18 | 51.8 | 59.0 | 120 | 158 |

| 20 | 73.0 | 85.0 | 146 | 194 |

| 24 | 122 | 140 | 210 | 282 |

| Poids approximatifs en kg, densité 8 kg/dm3 | ||||

AVAILABLE TYPES OF 180 DEGREE LONG RADIUS ELBOW

| Buttweld 180° Long Radius Elbow | Duplex Steel Buttweld 180° Long Radius Elbow |

| ASME B16.9 Butt weld 180° Long Radius Elbow | High Nickel Alloy 180° Long Radius Elbow |

| Stainless Steel 180° Long Radius Elbow | SS 180° Long Radius Elbow |

| High Quality 180° Long Radius Elbow | Seamless Butt weld 180° Long Radius Elbow |

| Welded Butt weld 180° Long Radius Elbowr | ASME B16.28 Buttweld 180° Long Radius Elbow |

| Carbon Steel 180° Long Radius Elbow | ANSI B16.9 Buttweld 180° Long Radius Elbow |

| Titanium Buttweld 180° Long Radius Elbow | Inconel Butt weld 180° Long Radius Elbow |

| ASTM A403 Stainless Steel 180° Long Radius Elbow | Butt Weld B16.9 180° Long Radius Elbow |

| Super Duplex Steel Buttweld 180° Long Radius Elbow | Copper Nickel 180° Long Radius Elbow |

| Steel 180° Long Radius Elbow | Hastelloy 180° Long Radius Elbow |

Fournisseur de tuyaux en acier inoxydable Wenzhou Kaixin Chine

Fournisseur de tuyaux en acier inoxydable Wenzhou Kaixin Chine