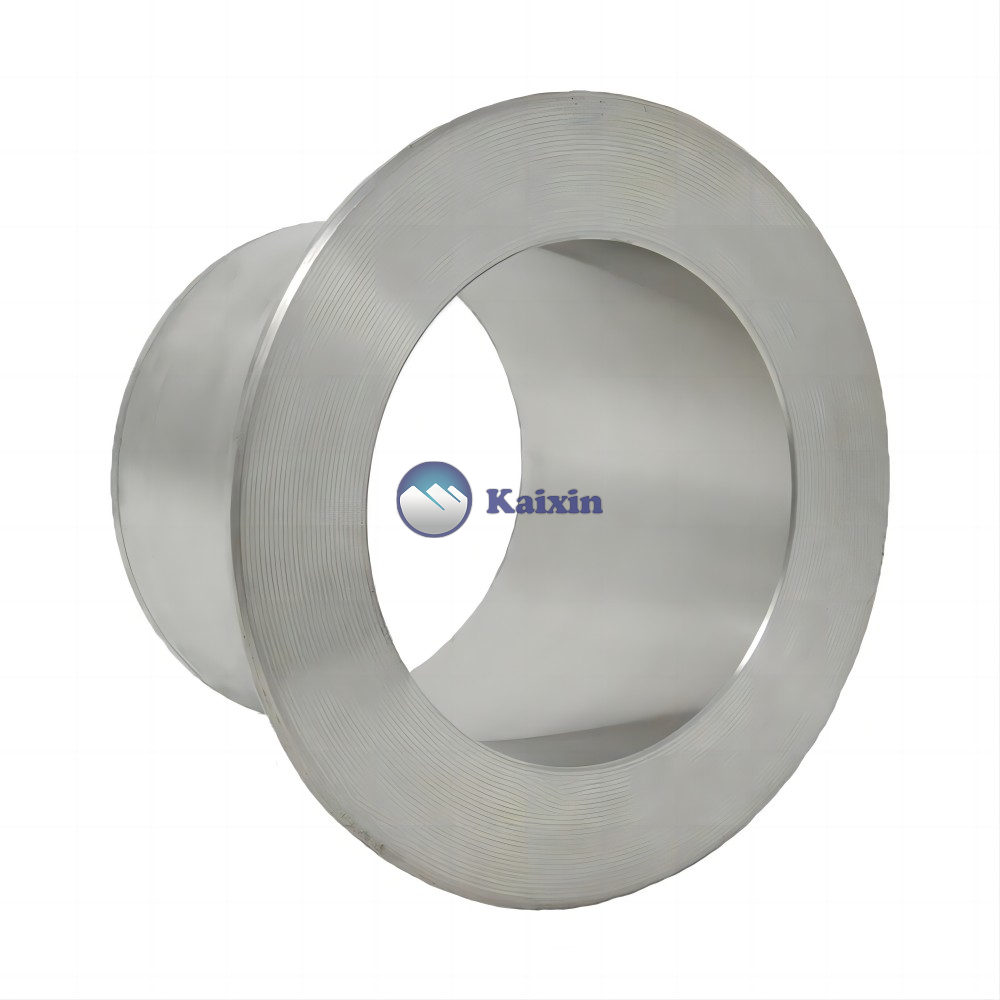

A stainless steel short stub end is a type of pipe fitting used in piping systems to connect two pipes of different sizes or materials. It is designed as a short length of pipe with one end shaped like a flange and the other end plain, allowing it to be welded to the pipe or fitting. The flange end is used to connect to a companion flange, making it easy to remove the joint for maintenance or repair. Stainless steel is used for its excellent resistance to corrosion and high temperatures, making it ideal for use in aggressive environments. Short stub ends are commonly used in petrochemical, chemical, and water treatment plants, as well as in food and beverage processing facilities.

Specification For Short Stub End

| आकार | 1/2” TO 36”, (Seamless up to 24”), (Welded 8” TO 36”) |

| मानकों | ANSI/ASME :ASTM A403 / ASME SA403, एएनएसआई बी16.9, ASME B16.25, एएसएमई बी16.28, MSS SP-43.DIN : DIN2605, DIN2615, DIN2616, DIN2617, DIN28011,में : EN10253-1, EN10253-2 |

| DIMENSIONS | एएसएमई/एएनएसआई बी16.9, एमएसएस-एसपी-43 टाइप ए, एमएसएस-एसपी-43 टाइप बी, जेआईएस बी2312, जेआईएस बी2313, एएसएमई बी16.28 |

| Thickness | अनुसूची 5एस, 10एस, 20एस, एस10, S20, S30, कक्षा, 40एस, एस40, S60, एक्सएस, 80एस, S80, एस100, S120, एस140, एस160, XXS और आदि. |

| झुकने वाली त्रिज्या | आर=1डी-10डी, 15डी, 20डी |

| से | Short Stub Ends, Pipe Stub Ends, Butt weld Short Stub Ends. |

| ग्रेड&सामग्री | एएसटीएम ए403 डब्ल्यूपी316/316एल, एएसटीएम ए403 एसए / ए 774 WP-एस, WP-W, WP-WX 304/304L, एएसटीएम ए182 एफ316एल, 304एल, से 1.4301, डीआईएन1.4306, से 1.4401, से 1.4404,एएसटीएम ए 815, एएसएमई एसए 815 यूएस नंबर S31803, S32205. यूएस एस32750, S32950. सामग्री संख्या. 1.4462,एएसटीएम ए234, एएसएमई SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.ASTM A420 WPL3, ए420 डब्लूपीएल6,एएसटीएम / एएसएमई ए/एसए 234 ग्रा. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91,एएसटीएम बी336, एएसएमई एसबी336, निकल 200 (यूएस नं. नंबर 2200), निकल 201 (यूएस नं. एन02201), मोनेल 400 (यूएस नं. एन04400), मोनेल 500 (यूएस नं. एन05500), Inconel 800 (यूएस नं. एन08800), Inconel 825 (यूएस नं. एन08825), Inconel 600 (यूएस नं. एन06600), Inconel 625 (यूएस नं. एन06625), Inconel 601 (यूएस नं. एन06601), हास्टेलॉय सी 276 (यूएस नं. एन10276), मिश्र धातु 20 (यूएस नं. N08020), टाइटेनियम (ग्रेड I & द्वितीय), ताम्र निकल 70/30, CuNi10Fe1Mn, CuNi30Mn1Fe. |

| प्रकार | निर्बाध / एकड़ / वेल्डेड / गढ़ा हुआ |

| Surface Coatings | Epoxy Coated, Black Painted, Varnished, Galvanized.Connection |

| Connection Type | End Bell / Threaded/ Clamp End / Weld/ Flange/ |

Short Stub End Manufacturing Standards

| ASME Standard | एएसएमई/एएनएसआई बी16.9, ASME/ANSI B16.28, MSS-SP-43 |

| DIN Standard | DIN28011, DIN2617, DIN2616, DIN2615, DIN2605 |

| EN Standard | EN10253-2, EN10253-1 |

| ASME B16.25 | Buttwelding Ends |

| ASME B16.9 | Factory-Made Wrought Fittings Buttwelding |

| एएसएमई बी16.28 | Wrought Steel Eccentric Reducer |

| ASTM A403 – ASME SA403 | Standard Specification for Wrought Austenitic Stainless Steel Piping Fitting |

| MSS SP-43 | Wrought & Fabricated Butt-Welding Fitting for Low Pressure, Corrosion Resistant Applications |

Short Stub End Materials and Grades

| Stainless Steel Buttweld Long Stub End | एएसटीएम ए403 डब्ल्यूपी316/316एल, एएसटीएम ए403 एसए / ए 774 WP-एस, WP-W, WP-WX 304/304L, एएसटीएम ए182 एफ316एल, 304एल, से 1.4301, डीआईएन1.4306, से 1.4401, से 1.4404 |

| दोहरा & Super Duplex Steel Buttweld Long Stub End | एएसटीएम ए 815, एएसएमई एसए 815 यूएस नंबर S31803, S32205. यूएस एस32750, S32950. सामग्री संख्या. 1.4462 |

| Carbon Steel Buttweld Long Stub End | एएसटीएम ए234, एएसएमई SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

| Low Temperature Carbon Steel Buttweld Long Stub End | एएसटीएम A420 WPL3, ए420 डब्लूपीएल6 |

| Alloy Steel Buttweld Long Stub End | एएसटीएम / एएसएमई ए/एसए 234 ग्रा. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

| Nickel Alloy Buttweld Long Stub End | एएसटीएम बी336, एएसएमई एसबी336, निकल 200 (यूएस नं. नंबर 2200), निकल 201 (यूएस नं. एन02201), मोनेल 400 (यूएस नं. एन04400), मोनेल 500 (यूएस नं. एन05500), Inconel 800 (यूएस नं. एन08800), Inconel 825 (यूएस नं. एन08825), Inconel 600 (यूएस नं. एन06600), Inconel 625 (यूएस नं. एन06625), Inconel 601 (यूएस नं. एन06601), हास्टेलॉय सी 276 (यूएस नं. एन10276), मिश्र धातु 20 (यूएस नं. N08020), टाइटेनियम (ग्रेड I & द्वितीय), ताम्र निकल 70/30, CuNi10Fe1Mn, CuNi30Mn1Fe. |

Short Stub End Types

Short Stub End are offered in three different ways, Type A, B and C. Type A and B stub end are similar to forged fittings, such as elbows and tees, and type C stub end are made in customized sizes.

Type A

The Type A Short Stub End is employed for standard joint flange. The lap thickness on the stub end is bigger than or up to the nominal thickness of pipe wall. Additionally, the outer corner radius of the sort A will receive the Long flange. The within corner is square. Lap sometimes includes a machined rough face.

Type B

The Type B Short Stub End is employed for standard slip on flanges as lap flanges. The lap thickness on these short ends is bigger than or up to the nominal thickness of pipe wall. Also, the outer corner radius of type B is tiny enough to receive the slip o flange which will be used as a backup flange. The inner corner is square. Short Stub End sometimes includes a machined rough face.

Type C

The Type C Short Stub End will be used for standard Long flange, and put on flange. It’s flaring feat a rounded edge at the within diameter of the lap. If necessary, the radius will be created closed to a square. The lap thickness is 75th of the pipe wall. The sort C is very short enough to accommodate any backup flange. The Short Stub End on kind C is smooth, and it’s not machined.The lap thickness is 75th of the pipe wall. The sort C is very short enough to accommodate any backup flange. The Long Stub End on kind C is smooth, and it’s not machined.

Short Stub End Dimensions

| उत्पाद | Nom. Pipe Size | Diameter (G) | Length (J) | घेरे के बाहर (O.D.) | Schedule 10S Approx. Weight | Schedule 10S, Inside Diameter (I.D.) | Schedule 10S, दीवार की मोटाई (T) | Schedule 5S Approx. Weight | अनुसूची 5एस, Inside Diameter (I.D.) | अनुसूची 5एस, दीवार की मोटाई (T) |

| 1 1/2″ Lap- Joint Stub End / Stub Ends Short Type “C” | 1.5 | 2.875 | 2 | 1.9 | 0.44 | 1.682 | 0.109 | 0.29 | 1.77 | 0.065 |

| 1 1/4″ Lap- Joint Stub End / Stub Ends Short Type “C” | 1.25 | 2.5 | 2 | 1.66 | 0.42 | 1.442 | 0.109 | 0.21 | 1.53 | 0.065 |

| 1″ Lap- Joint Stub End / Stub Ends Short Type “C” | 1 | 2 | 2 | 1.315 | 0.31 | 1.097 | 0.109 | 0.19 | 1.185 | 0.065 |

| 1/2″ Lap- Joint Stub End / Stub Ends Short Type “C” | 0.5 | 1.375 | 2 | 0.84 | 0.14 | 0.674 | 0.083 | 0.13 | 0.71 | 0.065 |

| 10″ Lap- Joint Stub End / Stub Ends Short Type “C” | 10 | 12.75 | 5 | 10.75 | 9.46 | 1042 | 0.165 | 7.48 | 10.482 | 0.134 |

| 12″ Lap- Joint Stub End / Stub Ends Short Type “C” | 12 | 15 | 6 | 12.75 | 16.07 | 12.39 | 0.18 | 15 | 12.438 | 0.156 |

| 14″ Lap- Joint Stub End / Stub Ends Short Type “C” | 14 | 16.25 | 6 | 14 | 23.1 | 13.624 | 0.188 | 19.2 | 13.688 | 0.156 |

| 16″ Lap- Joint Stub End / Stub Ends Short Type “C” | 16 | 18.5 | 6 | 16 | 27.2 | 15.624 | 0.188 | 23.9 | 15.67 | 0.165 |

| 18″ Lap- Joint Stub End / Stub Ends Short Type “C” | 18 | 21 | 6 | 18 | 32.4 | 17.624 | 0.188 | 28.5 | 17.67 | 0.165 |

| 2 1/2″ Lap- Joint Stub End / Stub Ends Short Type “C” | 2.5 | 4.125 | 2.5 | 2.875 | 1 | 2.635 | 0.12 | 0.75 | 2.709 | 0.083 |

| 2″ Lap- Joint Stub End / Stub Ends Short Type “C” | 2 | 3.625 | 2.5 | 2.375 | 0.81 | 2.157 | 0.109 | 0.44 | 2.245 | 0.065 |

| 20″ Lap- Joint Stub End / Stub Ends Short Type “C” | 20 | 23 | 6 | 20 | 47.7 | 19.564 | 0.218 | 36.3 | 19.624 | 0.188 |

| 24″ Lap- Joint Stub End / Stub Ends Short Type “C” | 24 | 27.25 | 6 | 24 | 58.27 | 23.5 | 0.25 | 56 | 23.564 | 0.218 |

| 3″ Lap- Joint Stub End / Stub Ends Short Type “C” | 3 | 5 | 2.5 | 3.5 | 1.25 | 3.26 | 0.12 | 0.94 | 3.334 | 0.083 |

| 3/4″ Lap- Joint Stub End / Stub Ends Short Type “C” | 0.75 | 1.688 | 2 | 1.05 | 0.18 | 0.884 | 0.083 | 0.14 | 0.92 | 0.065 |

| 4″ Lap- Joint Stub End / Stub Ends Short Type “C” | 4 | 6.188 | 3 | 4.5 | 1.88 | 4.26 | 0.12 | 1.38 | 4.334 | 0.083 |

| 5″ Lap- Joint Stub End / Stub Ends Short Type “C” | 5 | 7.313 | 3 | 5.563 | 2.63 | 5.295 | 0.134 | 2.06 | 5.345 | 0.109 |

| 6″ Lap- Joint Stub End / Stub Ends Short Type “C” | 6 | 8.5 | 3.5 | 6.625 | 3.56 | 6.357 | 0.134 | 2.75 | 6.407 | 0.109 |

| 8″ Lap- Joint Stub End / Stub Ends Short Type “C” | 8 | 10.625 | 4 | 8.625 | 6.19 | 8.329 | 0.148 | 3.88 | 8.407 | 0.109 |

| STUB ENDS – ANSI B 16.9 and MSS SP-43 dimension | |||||||

| इंच | रा | मिमी | Diameter of lap | Radius of fillet | Length F | ||

| डी | G | R | R1 | MSS SP43 | एएनएसआई बी16.9 | ||

| 1/2 | 15 | 21,34 | 34,92 | 3,17 | 0,80 | 50,80 | 76,20 |

| 3/4 | 20 | 26,67 | 42,86 | 3,17 | 0,80 | 50,80 | 76,20 |

| 1 | 25 | 33,40 | 50,80 | 3,17 | 0,80 | 50,80 | 101,60 |

| 1 1/4 | 32 | 42,16 | 63,50 | 4,76 | 0,80 | 50,80 | 101,60 |

| 1 1/2 | 40 | 48,26 | 73,00 | 6,35 | 0,80 | 50,80 | 101,60 |

| 2 | 50 | 60,32 | 92,10 | 7,93 | 0,80 | 63,50 | 152,40 |

| 2 1/2 | 65 | 73,02 | 104,80 | 7,93 | 0,80 | 63,50 | 152,40 |

| 3 | 80 | 88,90 | 127,00 | 9,52 | 0,80 | 63,50 | 152,40 |

| 3 1/2 | 90 | 101,60 | 139,70 | 9,52 | 0,80 | 76,20 | 152,40 |

| 4 | 100 | 114,30 | 157,20 | 11,11 | 0,80 | 76,20 | 152,40 |

| 5 | 125 | 141,30 | 185,70 | 11,11 | 1,58 | 76,20 | 203,20 |

| 6 | 150 | 168,27 | 215,90 | 12,70 | 1,58 | 88,90 | 203,20 |

| 8 | 200 | 219,07 | 269,80 | 12,70 | 1,58 | 101,60 | 203,20 |

| 10 | 250 | 273,05 | 323,80 | 12,70 | 1,58 | 127,00 | 254,00 |

| 12 | 300 | 323,85 | 381,00 | 12,70 | 1,58 | 152,40 | 254,00 |

| 14 | 350 | 355,60 | 412,70 | 12,70 | 1,58 | 152,40 | 304,80 |

| 16 | 400 | 406,40 | 469,90 | 12,70 | 1,58 | 152,40 | 304,80 |

| 18 | 450 | 457,20 | 533,40 | 12,70 | 1,58 | 152,40 | 304,80 |

| 20 | 500 | 508,00 | 584,20 | 12,70 | 1,58 | 152,40 | 304,80 |

| 22 | 550 | 558,80 | 641,30 | 12,70 | 1,58 | 152,40 | 304,80 |

| 24 | 600 | 609,60 | 692,10 | 12,70 | 1,58 | 152,40 | 304,80 |

| The lap thickness T shall not be less than nominal pipe wall thickness | |||||||

Short Stub End Length

| Nominal | अनुसूची | डी | टी | G | F | R. Max. | kg / St. | |

| 1/2 “ | 10s | 21.3 | 2.11 | 34.9 | 50.8 | 3.18 | 0.07 | s |

| 40s | 2.77 | 0.09 | s | |||||

| 3/4 “ | 10s | 26.7 | 2.11 | 42.9 | 50.8 | 3.18 | 0.10 | s |

| 40s | 2.87 | 0.12 | s | |||||

| 1 “ | 10s | 33.4 | 2.77 | 50.8 | 50.8 | 3.18 | 0.16 | s / w |

| 40s | 3.38 | 0.17 | s | |||||

| 1 1/4 “ | 10s | 42.2 | 2.77 | 63.5 | 50.8 | 4.76 | 0.22 | s |

| 40s | 3.56 | 0.25 | s | |||||

| 1 1/2 “ | 10s | 48.3 | 2.77 | 73.0 | 50.8 | 6.35 | 0.25 | s / w |

| 40s | 3.68 | 0.31 | s | |||||

| 2 “ | 10s | 60.3 | 2.77 | 92.1 | 63.5 | 7.94 | 0.43 | s / w |

| 40s | 3.91 | 0.61 | s | |||||

| 2 1/2 “ | 10s | 73.0 | 3.05 | 104.8 | 63.5 | 7.94 | 0.57 | s / w |

| 40s | 5.16 | 0.80 | s | |||||

| 3 “ | 10s | 88.9 | 3.05 | 127.0 | 63.5 | 9.53 | 0.73 | s / w |

| 40s | 5.49 | 1.13 | s | |||||

| 4 “ | 10s | 114.3 | 3.05 | 157.2 | 76.2 | 11.11 | 1.09 | s / w |

| 40s | 6.02 | 1.87 | s | |||||

| 5 “ | 10s | 141.3 | 3.40 | 185.7 | 76.2 | 11.11 | 1.47 | s / w |

| 40s | 6.55 | 2.28 | s | |||||

| 6 “ | 10s | 168.3 | 3.40 | 215.9 | 88.9 | 12.70 | 2.15 | s / w |

| 40s | 7.11 | 3.57 | s / w | |||||

| 8 “ | 10s | 219.1 | 3.76 | 269.9 | 101.6 | 12.70 | 3.22 | s / w |

| 40s | 8.18 | 6.07 | s / w | |||||

| 10 “ | 10s | 273.1 | 4.19 | 323.9 | 127.0 | 12.70 | 5.13 | w |

| 40s | 9.27 | 10.07 | w | |||||

| 12 “ | 10s | 323.9 | 4.57 | 381.0 | 152.4 | 12.70 | 8.16 | w |

| 40s | 9.53 | 14.29 | w | |||||

| 14 “ | 10s | 355.6 | 4.78 | 412.8 | 152.4 | 12.70 | 10.89 | w |

| 40s | 9.53 | 17.15 | w | |||||

| 16 “ | 10s | 406.4 | 4.78 | 469.9 | 152.4 | 12.70 | 12.70 | w |

| 40s | 9.53 | 20.41 | w | |||||

| 18 “ | 10s | 457.2 | 4.78 | 533.4 | 152.4 | 12.70 | 17.24 | w |

| 20 “ | 10s | 508.0 | 5.54 | 584.2 | 152.4 | 12.70 | 21.77 | w |

| 24 “ | 10s | 609.6 | 6.35 | 692.2 | 152.4 | 12.70 | 27.22 | w |

Short Stub End Dimensional Tolerance

MSS SP-43 solely covers Stainless Steel Butt Weld Long Stub End Fittings created to be used with Schedule 5S and 10S Long Stub End appropriate to be used with Schedule 40S Pipe, as outlined in ASME B36.19. The scale and dimensional tolerances outlined in MSS SP-43 area unit considerably a similar as those in ASME B16.9 specifications from NPS 1/2 — NPS Twenty-four. Except with relation to the skin diameter at the bevel.

| Long Stub Ends | ||

| ओ.डी. of Lap G | Fillet Radius of Lap – R | Overall Length. – F |

| +0 -1 | +0-1 | 2 |

| +0 -1 | +0-1 | 2 |

| +0 -1 | +0 -2 | 2 |

| +0-1 | +0 -2 | 2 |

| +0 -1 | +0 -2 | 2 |

| +0 -2 | +0 -2 | 2 |

| +0 -2 | +0-2 | 3 |

| +0 -2 | +0 -2 | 3 |

Short Stub End Weight Chart

| एनपीएस इंच |

STUB ENDS | |||

| एसएच. 5एस |

एसएच. 10एस |

एसएच. 40एस |

एसएच. 80एस |

|

| 1/2 | 0.06 | 0.08 | 0.12 | 0.13 |

| 3/4 | 0.07 | 0.09 | 0.15 | 0.17 |

| 1 | 0.09 | 0.15 | 0.20 | 0.25 |

| 1 1/4 | 0.13 | 0.20 | 0.30 | 0.35 |

| 1 1/2 | 0.16 | 0.25 | 0.38 | 0.46 |

| 2 | 0.25 | 0.40 | 0.55 | 0.75 |

| 2 1/2 | 0.35 | 0.50 | 0.80 | 1.00 |

| 3 | 0.50 | 0.60 | 1.10 | 1.50 |

| 4 | 0.70 | 1.00 | 1.80 | 2.50 |

| 5 | 1.00 | 1.25 | 2.50 | 3.50 |

| 6 | 1.60 | 1.95 | 3.70 | 5.50 |

| 8 | 2.50 | 3.10 | 5.90 | 10.0 |

| 10 | 4.00 | 4.90 | 10.5 | 14.0 |

| 12 | 6.60 | 7.10 | 15.0 | 20.0 |

| 14 | 6.40 | 7.80 | 15.5 | 20.5 |

| 16 | 7.90 | 9.00 | 18.0 | 24.0 |

| 18 | 9.30 | 10.5 | 21.0 | 28.0 |

| 20 | 12.0 | 13.5 | 23.5 | 31.0 |

| 24 | 16.5 | 19.0 | 28.5 | 38.0 |

| किलोग्राम में अनुमानित वजन, घनत्व 8 किग्रा/डीएम3 | ||||

Short Stub End Angularity Tolerance

| रा | अधिकतम ऑफ एंगल | अधिकतम विमान से बाहर |

| क्यू | पी | |

| 1/2 ए 4 | 1 | 2 |

| 5 ए 8 | 2 | 4 |

| 10 ए 12 | 3 | 5 |

| 14 ए 16 | 3 | 7 |

| 18 ए 24 | 4 | 10 |

| 26 ए 30 | 5 | 10 |

| 32 ए 42 | 5 | 13 |

| 44 ए 48 | 5 | 20 |

ASME B16.9 Buttweld Short Stub End Available Types

| Buttweld Short Stub End | Butt Weld Short Stub Ends |

| ASME B16.9 Butt weld Short Stub End | Steel Short Stub Ends Fittings |

| Stainless Steel Short Stub End Suppliers | SS Buttweld Short Stub Ends Fitting |

| ANSI B16.9 Buttweld Short Stub End Dealer | ASME B16.28 Buttweld Short Stub Ends Exporter |

| Welded Butt weld Short Stub Ends Stockholder | Seamless Butt weld Short Stub End Distributors |

| Carbon Steel Short Stub End | High Quality Short Stub End Manufacturer |

| ASTM A403 Stainless Steel Short Stub Ends | Duplex Steel Buttweld Short Stub End |

| Super Duplex Steel Buttweld Short Stub End | Copper Nickel Short Stub End |

| High Nickel Alloy Short Stub Ends | Hastelloy Short Stub Ends Stockist |

| Titanium Buttweld Short Stub End | Inconel Butt weld Short Stub End |

Short Stub End Application

- Stainless Steel Buttweld Short Stub End uses in Oil and Gas Pipeline

- Butt weld Short Stub Ends uses in Chemical Industry

- Alloy Steel Short Stub Ends uses in Plumbing

- Buttweld Short Stub Ends uses in Heating

- Buttweld Short Stub End Fittings uses in Water Supply Systems

- ANSI B16.9 Buttweld Short Stub Ends uses in Power Plant

- Buttweld Short Stub End Fitting uses in Paper & लुगदी उद्योग

- Short Stub End uses in General Purpose Applications

- Buttweld Short Stub End uses in Fabrication Industry

- Short Stub End uses in Food Processing Industry

- Buttweld Short Stub Ends uses in Structural Pipe

स्टेनलेस स्टील पाइप आपूर्तिकर्ता वानजाउ कैक्सिन चीन

स्टेनलेस स्टील पाइप आपूर्तिकर्ता वानजाउ कैक्सिन चीन