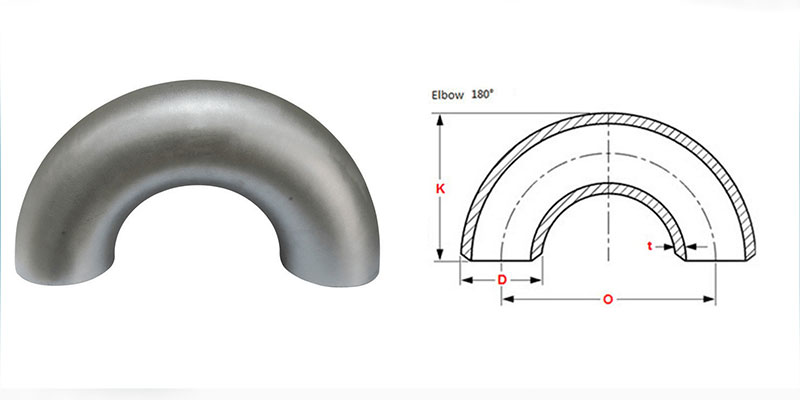

An elbow is the pipe fittings that are used extensively as a form of connections in between two lengths of pipes for the purpose of producing the change into the flow direction into the pipe, at the angle of 180 derajat, 90 deg or 45 derajat. Elbow pipe fitting is also called as the bend that is available in the ranges of materials including alloy steel, baja karbon, stainless steel, nickel alloy, super duplex, rangkap, and cupro-nickel, dll.. 180° Long Radius Elbow is also termed as the return bend that permits the complete reversal of the flow. The distance in between the center line and end of the elbow is 3 x NPS.

Some qualities of it are High mechanical strength rugged construction, Smoothness in surface finishes, Perfect dimensional accuracy, Anti-corrosive body, and Pitting and oxidation resistance.

180 DEGREE LONG RADIUS ELBOW SPECIFICATIONS

| Diameter luar (DARI) | Seamless 180° Long Radius Elbow (1/2″~24″), hektar / Siku Pabrikan / Lasan (1/2″~48″) |

| Standar | ANSI – B 16.9,ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’API 590-605,ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings”,ASME B16.25 – 'Pengelasan Butt Berakhir',ASME B16.28 – 'Siku dan Pengembalian Buttwelding Baja Tempa',MSS SP-43 – 'Perlengkapan Pengelasan Butt Tempa dan Pabrikasi untuk Tekanan Rendah, Aplikasi Tahan Korosi' |

| Ukuran | ASME/ANSI B16.9, MSS-SP-43 Tipe A, MSS-SP-43 Tipe B, JIS B2312, JIS B2313, ASME B16.28 |

| Jadwal | Jadwalkan 5S, 10S, 20S, S10, S20, S30, PMS, 40S, S40, S60, X, 80S, S80, S100, S120, S140, S160, XXS dan lain-lain. |

| Radius Lentur | R=1D – 10D, 15D, 20D |

| Dari | 180° Siku Radius Panjang, Butt weld 180° Long Radius Elbow. |

| Bahan | 304/W/H/LN, 316/L/H/LN/Ti, 321/H, 317/L/LN, 347/H, 310SH, N08904(904L), S31803,S32205, S32750, S32760, N02200, N02201, N04400, N06600, N06690, N06625, N06985(G3), N08028, N08800, N08810, N08811, N08825Permukaan,Monel, Nikel, tidak konel, Hastalloy, titanium, Tantalum, Besi tahan karat, Baja Paduan, Baja karbon, Cupro-Nikel 90/10 & 70/30, ASME Baja Tahan Karat / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, DARI 1.4301, DIN1.4306, DARI 1.4401, DARI 1.4404 |

| Jenis | Pengelasan Bokong (BW) / Lasan / hektar / Dibuat |

| Titik Leleh SS | 1400-1450°C (WP304, WP304L), 1390-1440 °C (WP316L), 1370 – 1400 °C (WP316) |

180 DERAJAT PANJANG RADIUS SIKU – BAHAN & KELAS

| Buttweld Baja Tahan Karat 180 Derajat Siku Radius Panjang | ASTM A403 WP316/316L, ASTM A403 SA / A 774 WP-S, WP-W, WP-WX 304/304L, ASTM A182 F316L, 304L, DARI 1.4301, DIN1.4306, DARI 1.4401, DARI 1.4404 |

| Rangkap & Buttweld Baja Super Dupleks 180 Derajat Siku Radius Panjang | ASTM A 815, ASME SA 815 UNS NO S31803, S32205. S32750 AS, S32950. Nomor Bahan. 1.4462 |

| Buttweld Baja Karbon 180 Derajat Siku Radius Panjang | ASTM A234, ASME SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

| Baja Karbon Suhu Rendah 180 Derajat Siku Radius Panjang | ASTM A420 WPL3, A420 WPL6 |

| Buttweld Baja Paduan 180 Derajat Siku Radius Panjang | ASTM / ASME A/S.A 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

| Buttweld Paduan Nikel 180 Derajat Siku Radius Panjang | ASTM B336, ASME SB336, Nikel 200 (UNS no. No2200), Nikel 201 (UNS no. N02201), Monel 400 (UNS no. N04400), Monel 500 (UNS no. N05500), tidak konel 800 (UNS no. N08800), tidak konel 825 (UNS no. N08825), tidak konel 600 (UNS no. N06600), tidak konel 625 (UNS no. N06625), tidak konel 601 (UNS no. N06601), Hastelloy C 276 (UNS no. N10276), Paduan 20 (UNS no. N08020), titanium (kelas I & II), Cupro-Nikel 70/30, CuNi10Fe1Mn, CuNi30Mn1Fe. |

Buttweld 180 Industri Aplikasi Siku Radius Panjang Deg

- Industri Petrokimia

- Industri kimia

- Industri Minyak dan Gas Bumi

- Bubur & Paper Indusry

- Industri Pembangkit Listrik

- Industri Pengolahan Makanan

- Industri Farmasi

- Industri Energi

- Industri Dirgantara

DIMENSI 180 DEGREE LONG RADIUS ELBOW – ANSI 16.9

ASME B16.9 Buttweld 180° Short Radius Elbow Dimensions Drawing

| Ukuran pipa nominal | Diameter luar

di Bevel |

Center to Center | Back to Faces | ||||

| 180° Return | |||||||

| P | K | ||||||

| hari | INCH | Series A | Series B | LR | LR | ||

| 15 | 1/2 | 21.3 | 18 | 76 | 48 | ||

| 20 | /4 | 26.9 | 25 | 76 | 51 | ||

| 25 | 1 | 33.7 | 32 | 76 | 56 | ||

| 32 | 11/4 | 42.4 | 38 | 95 | 70 | ||

| 40 | 11/2 | 48.3 | 45 | 114 | 83 | ||

| 50 | 2 | 60.3 | 57 | 152 | 106 | ||

| 65 | 21/2 | 76.1(73) | 76 | 191 | 132 | ||

| 80 | 3 | 88.9 | 89 | 229 | 159 | ||

| 90 | 31/2 | 101.6 | – | 267 | 184 | ||

| 100 | 4 | 114.3 | 108 | 305 | 210 | ||

| 125 | 5 | 139.7 | 133 | 381 | 262 | ||

| 150 | 6 | 168.3 | 159 | 457 | 313 | ||

| 200 | 8 | 219.1 | 219 | 610 | 414 | ||

| 250 | 10 | 273.0 | 273 | 762 | 518 | ||

| 300 | 12 | 323.9 | 325 | 914 | 619 | ||

| 350 | 14 | 355.6 | 377 | 1067 | 711 | ||

| 400 | 16 | 406.4 | 426 | 1219 | 813 | ||

| 450 | 18 | 457.2 | 478 | 1372 | 914 | ||

| 500 | 20 | 508.0 | 529 | 1524 | 1016 | ||

| 550 | 22 | 559 | – | · 180 Degree Elbows – It is used when change in the direction of pipe required is 180°

· L/R – Long radius |

|||

| 600 | 24 | 610 | 630 | ||||

| 650 | 26 | 660 | – | ||||

| 700 | 28 | 711 | 720 | ||||

| 750 | 30 | 762 | – | ||||

| 800 | 32 | 813 | 820 | ||||

| 850 | 34 | 864 | – | ||||

| 900 | 36 | 914 | 920 | ||||

| 950 | 38 | 965 | – | ||||

| 1000 | 40 | 1016 | 1020 | ||||

| 1050 | 42 | 1067 | – | ||||

| 1100 | 44 | 1118 | 1120 | ||||

| 1150 | 46 | 1168 | – | ||||

| 1200 | 48 | 1220 | 1220 | ||||

TOLERANSI DIMENSI 180 DEGREE LONG RADIUS ELBOW – ASME B16.9

| For all Pipe Fittings | 180° Kembali | |||||

| Ukuran Pipa Nominal (NPC) | Ketebalan dinding

T / t1 |

Di luar Ø

di Bevel |

Di dalam Ø

di Akhir |

Kembali ke Wajah Redup.

K |

Pusat ke Pusat Redup.

HAI |

Meluruskan- ment dari Berakhir

kamu |

| 1/2 A 2 1/2 | Bukan | 1 | 0,8 | 7 | 7 | 1 |

| 3 A 3 1/2 | lebih sedikit | 1 | 1,6 | 7 | 7 | 1 |

| 4 | dibandingkan | +2 -1 | 1,6 | 7 | 7 | 1 |

| 5 A 6 | 87,50% | +3 -1 | 1,6 | 7 | 7 | 1 |

| 8 | dari nominal | 2 | 1,6 | 7 | 7 | 1 |

| 10 | ketebalan | +4 -3 | 3,2 | 7 | 7 | 2 |

| 12 A 18 | 3,2 | +4 -3 | 7 | 10 | 2 | |

| 20 A 24 | 4,8 | +6 -5 | 7 | 10 | 2 | |

| 26 A 30 | 4,8 | +7 -5 | ….. | ….. | ….. | |

| 32 A 48 | 4,8 | +7 -5 | ….. | ….. | ….. | |

ASME B16.9 180° Long Radius Elbow Angularity Tolerance

| tidak | Sudut maksimal | Maks turun dari pesawat |

| Q | P | |

| 1/2 A 4 | 1 | 2 |

| 5 A 8 | 2 | 4 |

| 10 A 12 | 3 | 5 |

| 14 A 16 | 3 | 7 |

| 18 A 24 | 4 | 10 |

| 26 A 30 | 5 | 10 |

| 32 A 42 | 5 | 13 |

| 44 A 48 | 5 | 20 |

GRAFIK BERAT BADAN 180° DERAJAT PANJANG RADIUS SIKU

| NPC

inci |

ELBOWS LR 180° | |||

| Sch.

5S |

Sch.

10S |

Sch.

40S |

Sch.

80S |

|

| 1/2 | 0.05 | 0.06 | 0.08 | 0.10 |

| 3/4 | 0.06 | 0.07 | 0.09 | 0.11 |

| 1 | 0.09 | 0.15 | 0.18 | 0.20 |

| 1 1/4 | 0.13 | 0.20 | 0.25 | 0.35 |

| 1 1/2 | 0.18 | 0.30 | 0.40 | 0.50 |

| 2 | 0.30 | 0.50 | 0.70 | 0.90 |

| 2 1/2 | 0.60 | 0.85 | 1.35 | 1.80 |

| 3 | 0.90 | 1.30 | 2.00 | 2.90 |

| 4 | 1.40 | 2.00 | 4.00 | 5.90 |

| 5 | 2.90 | 3.60 | 6.50 | 9.70 |

| 6 | 4.00 | 5.00 | 10.5 | 16.0 |

| 8 | 7.40 | 10.0 | 21.5 | 33.5 |

| 10 | 13.6 | 16.8 | 38.5 | 52.5 |

| 12 | 23.4 | 27.0 | 59.0 | 79.0 |

| 14 | 29.0 | 35.0 | 70.0 | 94.0 |

| 16 | 41.3 | 47.0 | 95.0 | 125 |

| 18 | 51.8 | 59.0 | 120 | 158 |

| 20 | 73.0 | 85.0 | 146 | 194 |

| 24 | 122 | 140 | 210 | 282 |

| Perkiraan berat dalam kg, kepadatan 8 kg/dm3 | ||||

JENIS YANG TERSEDIA 180 DERAJAT PANJANG RADIUS SIKU

| Buttweld 180° Long Radius Elbow | Duplex Steel Buttweld 180° Long Radius Elbow |

| ASME B16.9 Butt weld 180° Long Radius Elbow | High Nickel Alloy 180° Long Radius Elbow |

| Stainless Steel 180° Long Radius Elbow | SS 180° Long Radius Elbow |

| High Quality 180° Long Radius Elbow | Seamless Butt weld 180° Long Radius Elbow |

| Welded Butt weld 180° Long Radius Elbowr | ASME B16.28 Buttweld 180° Long Radius Elbow |

| Carbon Steel 180° Long Radius Elbow | ANSI B16.9 Buttweld 180° Long Radius Elbow |

| Titanium Buttweld 180° Long Radius Elbow | Inconel Butt weld 180° Long Radius Elbow |

| ASTM A403 Stainless Steel 180° Long Radius Elbow | Butt Weld B16.9 180° Long Radius Elbow |

| Super Duplex Steel Buttweld 180° Long Radius Elbow | Copper Nickel 180° Long Radius Elbow |

| Steel 180° Long Radius Elbow | Hastelloy 180° Long Radius Elbow |

Pemasok Pipa Stainless Steel Wenzhou Kaixin Cina

Pemasok Pipa Stainless Steel Wenzhou Kaixin Cina