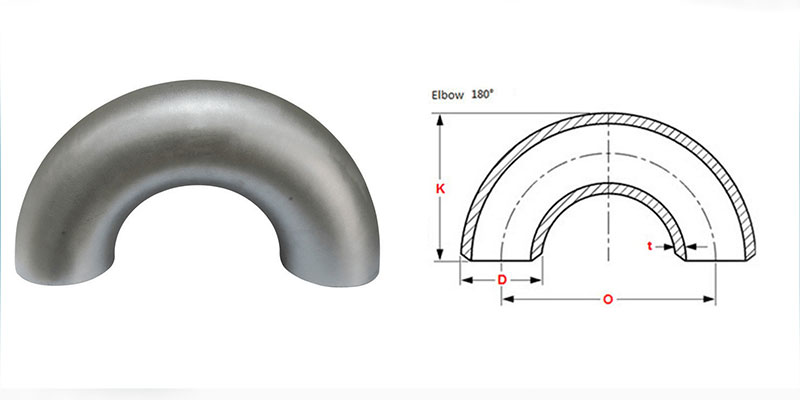

UN 180 degree short radius elbow is a pipe fitting that is used to connect two pipes at an angle of 180 gradi. The short radius elbow has a smaller radius of curvature than the long radius elbow, which means it is more compact and has a tighter turning radius. This fitting is typically made of carbon steel, acciaio inossidabile, or other metals and is used in various industries such as oil and gas, petrolchimici, and power generation. Its main purpose is to change the direction of the pipeline and to prevent fluid flow from being obstructed.

180 DEGREE SHORT RADIUS ELBOW SPECIFICATIONS

| Diametro esterno (DI) | Seamless 90° Short Radius Elbow (1/2″~24″), ACRI / Gomito fabbricato / Saldato (1/2″~48″) |

| Standard | ANSI-B 16.9, ASTM A403 – ASME SA403 – “Specifiche standard per raccordi per tubazioni in acciaio inossidabile austenitico lavorato”, API 590-605, ASME B16.9 – “Raccordi saldati di testa lavorati in fabbrica”, ASME B16.25 – "Estremità saldate di testa", ASME B16.28 – "Gomiti e ritorni a corto raggio con saldatura di testa in acciaio battuto", MSS SP-43 – "Raccordi a saldare di testa lavorati e fabbricati per bassa pressione"., Applicazioni resistenti alla corrosione |

| Dimensioni | ASME/ANSI B16.9, MSS-SP-43 Tipo A, MSS-SP-43 Tipo B, JIS B2312, JIS B2313, ASME B16.28 |

| Programma | Programma 5S, 10S, 20S, S10, S20, S30, ST, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS e così via. |

| Raggio di curvatura | R=1D – 10D, 15D, 20D |

| Da | 180° Short Radius Elbow, Butt weld 180° Short Radius Elbow. |

| Materiali | 304/L/H/LN, 316/L/H/LN/Ti, 321/H, 317/L/LN, 347/H, 310SH, N08904(904l), S31803,S32205, S32750, S32760, N02200, N02201, N04400, N06600, N06690, N06625, N06985(G3), N08028, N08800, N08810, N08811, N08825Superficie,Monel, Nichel, Inconel, Hastalloy, Titanio, Tantalio, Acciaio inossidabile, Acciaio legato, Acciaio al carbonio, Cupro-nichel 90/10 & 70/30, ASME in acciaio inossidabile / ASTMSA / A403SA / UN 774 WP-S, WP-W, WP-WX, DA 1.4301, DIN1.4306, DA 1.4401, DA 1.4404 |

| Tipo | Saldatura di testa (BW) / Saldato / ACRI / Fabbricato |

| Punti di fusione degli SS | 1400-1450°C (WP304, WP304L), 1390-1440 °C (WP316L), 1370 – 1400 °C (WP316) |

180 DEGREE SHORT RADIUS ELBOW – MATERIALS & GRADI

| Saldatura di testa in acciaio inossidabile 180 Gomito a raggio corto di grado | ASTM A403 WP316/316L, ASTM A403SA / UN 774 WP-S, WP-W, WP-WX304/304L, ASTM A182 F316L, 304l, DA 1.4301, DIN1.4306, DA 1.4401, DA 1.4404 |

| Duplex & Saldatura di testa in acciaio super duplex 180 Gomito a raggio corto di grado | ASTM A 815, ASME SA 815 USA N. S31803, S32205. USA S32750, S32950. Materiale n. 1.4462 |

| Saldatura di testa in acciaio al carbonio 180 Gomito a raggio corto di grado | ASTM A234, ASME SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

| Acciaio al carbonio a bassa temperatura 180 Gomito a raggio corto di grado | ASTM A420 WPL3, A420WPL6 |

| Saldatura di testa in acciaio legato 180 Gomito a raggio corto di grado | ASTM / ASME A/SA 234 gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

| Saldatura di testa in lega di nichel 180 Gomito a raggio corto di grado | ASTM B336, ASME SB336, Nichel 200 (UNS n. No2200), Nichel 201 (UNS n. N02201), Monel 400 (UNS n. N04400), Monel 500 (UNS n. N05500), Inconel 800 (UNS n. N08800), Inconel 825 (UNS n. N08825), Inconel 600 (UNS n. N06600), Inconel 625 (UNS n. N06625), Inconel 601 (UNS n. N06601), Hastelloy C 276 (UNS n. N10276), Lega 20 (UNS n. N08020), Titanio (Grado I & II), Cupro-nichel 70/30, CuNi10Fe1Mn, CuNi30Mn1Fe. |

180 DEGREE SHORT RADIUS ELBOW APPLICATION INDUSTRIES

ASME/ANSI B16.9 180° Short Radius Elbow are known to deliver exceptional performance and are generally developed for meeting the demands. We supply a wide range of Buttweld 180° SR Elbow through a worldwide network of stock-keeping branches. These Butt weld 180° Short Radius Elbow is uses in various industries According to needs. Most Common Indusctris are:

- Stainless Steel 180° Short Radius Elbow uses in Oil and Gas Pipeline

- 180° Buttweld SR Elbow uses in Chemical Industry

- Alloy Steel 180° Short Radius Elbow uses in Plumbing

- 180° Short Radius Elbow Pipe Fittings uses in Food Processing Industry

- Buttweld 180° SR Elbow uses in Structural Pipe

- ANSI B16.9 Buttweld 180° Short Radius Elbow uses in Power Plant

- 180° Short Radius Pipe Elbow uses in Paper & Pulp Industry

- 180 Deg Short Radius Bend uses in Heating

- 180 Degree Short Radius Reducing Elbow uses in Water Supply Systems

- ASME B16.9 Short Radius 180 Deg Elbow uses in General Purpose Applications

- 180° SR Elbow uses in Fabrication Industry

ASME B16.9 Buttweld 180° Short Radius Elbow Dimensions

ASME B16.9 Buttweld 180 ° Dimensione del gomito a raggio corto

| NPS | O.D. D | 180° Short Radius | |

| Center al centro

O |

Back to Face

K |

||

| 1/2 | 21.3 | 76 | 48 |

| 3/4 | 26.7 | 76 | 51 |

| 1 | 33.4 | 76 | 56 |

| 1¼ | 42.2 | 95 | 70 |

| 1½ | 48.3 | 114 | 83 |

| 2 | 60.3 | 152 | 106 |

| 2½ | 73 | 190 | 132 |

| 3 | 88.9 | 229 | 159 |

| 3½ | 101.6 | 267 | 184 |

| 4 | 114.3 | 305 | 210 |

| 5 | 141.3 | 381 | 262 |

| 6 | 168.3 | 457 | 313 |

| 8 | 219.1 | 610 | 414 |

| 10 | 273 | 762 | 518 |

| 12 | 323.8 | 914 | 619 |

| 14 | 355.6 | 1067 | 711 |

| 16 | 406.4 | 1219 | 813 |

| 18 | 457 | 1372 | 914 |

| 20 | 508 | 1524 | 1016 |

| 22 | 559 | 1676 | 1118 |

| 24 | 610 | 1829 | 1219 |

180 Degree Short Radius Elbow Dimensions Tolerance

MSS SP-43 only covers Stainless Steel 180° SR Radius Elbow made for use with Schedule 5S and 10S pipe and Stub Ends suitable for use with Schedule 40S pipe, come definito in ASME B36.19. Le dimensioni e le tolleranze dimensionali definite in MSS SP-43 sono sostanzialmente le stesse delle specifiche ASME B16.9 di NPS 1/2 – NPS 24. Tranne per quanto riguarda il diametro esterno dello smusso.

| Dimensione nominale del tubo | 1/2 to 2.1/2 | 3 to 3.1/2 | 4 |

| Diametro esterno

a Bevel (D) |

+ 1.6

– 0.8 |

1.6 | 1.6 |

| Inside Diameter at End | 0.8 | 1.6 | 1.6 |

| Center al centro (O) | 6 | 6 | 6 |

| Back to Face (K) | 6 | 6 | 6 |

| Dimensione nominale del tubo | 5 to 8 | 10 to 18 | 20 to 24 |

| Diametro esterno

a Bevel (D) |

+ 2.4

– 1.6 |

+ 4

– 3.2 |

+ 6.4

– 4.8 |

| Inside Diameter at End | 1.6 | 3.2 | 4.8 |

| Center al centro (O) | 6 | 10 | 10 |

| Back to Face (K) | 6 | 6 | 6 |

| Spessore del muro (T) | Not less than 87.5% of Nominal Wall Thickness | ||

ASME B16.9 180° Short Radius Elbow Angularity Tolerance

| ND | Angolo massimo | Max fuori dall'aereo |

| Q | P | |

| 1/2 UN 4 | 1 | 2 |

| 5 UN 8 | 2 | 4 |

| 10 UN 12 | 3 | 5 |

| 14 UN 16 | 3 | 7 |

| 18 UN 24 | 4 | 10 |

| 26 UN 30 | 5 | 10 |

| 32 UN 42 | 5 | 13 |

| 44 UN 48 | 5 | 20 |

TABELLA DEL PESO DI 180 DEGREE SHORT RADIUS ELBOW

| NPS

pollici |

ELBOWS SR 180° | |||

| Sch.

5S |

Sch.

10S |

Sch.

40S |

Sch.

80S |

|

| 1/2 | 0.05 | 0.06 | 0.08 | 0.10 |

| 3/4 | 0.06 | 0.07 | 0.09 | 0.11 |

| 1 | 0.09 | 0.15 | 0.18 | 0.20 |

| 1 1/4 | 0.13 | 0.20 | 0.25 | 0.35 |

| 1 1/2 | 0.18 | 0.30 | 0.40 | 0.50 |

| 2 | 0.30 | 0.50 | 0.70 | 0.90 |

| 2 1/2 | 0.60 | 0.85 | 1.35 | 1.80 |

| 3 | 0.90 | 1.30 | 2.00 | 2.90 |

| 4 | 1.40 | 2.00 | 4.00 | 5.90 |

| 5 | 2.90 | 3.60 | 6.50 | 9.70 |

| 6 | 4.00 | 5.00 | 10.5 | 16.0 |

| 8 | 7.40 | 10.0 | 21.5 | 33.5 |

| 10 | 13.6 | 16.8 | 38.5 | 52.5 |

| 12 | 23.4 | 27.0 | 59.0 | 79.0 |

| 14 | 29.0 | 35.0 | 70.0 | 94.0 |

| 16 | 41.3 | 47.0 | 95.0 | 125 |

| 18 | 51.8 | 59.0 | 120 | 158 |

| 20 | 73.0 | 85.0 | 146 | 194 |

| 24 | 122 | 140 | 210 | 282 |

| Pesi approssimativi in kg, densità 8 kg/dm3 | ||||

TIPOLOGIE DISPONIBILI DI 180 DEGREE SHORT RADIUS ELBOW

| High Quality 180° Short Radius Elbow | Stainless Steel 180° Short Radius Elbow |

| Welded Butt weld 180° Short Radius Elbowr | Carbon Steel 180° Short Radius Elbow |

| ASME B16.28 Buttweld 180° Short Radius Elbow | ANSI B16.9 Buttweld 180° Short Radius Elbow |

| Buttweld 180° Short Radius Elbow | High Nickel Alloy 180° Short Radius Elbow |

| ASME B16.9 Butt weld 180° Short Radius Elbow | Duplex Steel Buttweld 180° Short Radius Elbow |

| Seamless Butt weld 180° Short Radius Elbow | SS 180° Short Radius Elbow |

| Titanium Buttweld 180° Short Radius Elbow | Inconel Butt weld 180° Short Radius Elbow |

| Super Duplex Steel Buttweld 180° Short Radius Elbow | Copper Nickel 180° Short Radius Elbow |

| Steel 180° Short Radius Elbow | Hastelloy 180° Short Radius Elbow |

| ASTM A403 Stainless Steel 180° Short Radius Elbow | Butt Weld B16.9 180° Short Radius Elbow |

Fornitore di tubi in acciaio inossidabile Wenzhou Kaixin Cina

Fornitore di tubi in acciaio inossidabile Wenzhou Kaixin Cina