A stainless steel reducing cross is a type of pipe fitting that allows for the connection of four pipes of different sizes. It has a cross-shaped design with one inlet and three outlets, each with a different diameter size. The reducing cross is made of stainless steel, which gives it excellent durability and corrosion resistance, making it suitable for use in harsh industrial environments. It is commonly used in piping systems that require the merging or splitting of fluid flow from multiple sources. The reducing cross is available in different sizes and configurations to meet specific application requirements.

Specifications of Reducing Cross

| Sizes | Seamless Pipe Equal Cross ( 1/2″~24″), ERW / Welded / Fabricated Pipe Equal Cross (1/2″~48″) |

| Standards | ANSI – B 16.9, ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings’, API 590-605, ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings”, ASME B16.25 – ‘Buttwelding Ends’, ASME B16.28 – ‘Wrought Steel Buttwelding Short Radius Elbows and Returns’, MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’ |

| Dimensions | ASME/ANSI B16.9, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313, ASME B16.28 |

| Thickness | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Bending Radius | R=1D – 10D, 15D, 20D

|

| From | Unequal Cross, Reducing Cross, Pipe Cross, Butt weld Unequal Cross. |

| Grades&Materials | ASTM A403 WP316/316L, ASTM A403 WP304/304L, ASTM A182 F316L, 304L, NUO 1.4301, DIN1.4306, NUO 1.4401, NUO 1.4404, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L,ASTM A234, ASME SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. ASME SA234 WP1 / WP5 / WP9 / WP11 / WP22 / WP91, ASTM A815, ASME SA815 UNS No S31803, S32205,S32750, S32950, ASTM B336, ASME SB336, Nickel 200 (UNS No. No2200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Lydinys 20 (UNS No. N08020), Titanium (Grade I & II), Cupro-Nickel 70/30, CuNi10Fe1Mn, CuNi30Mn1Fe.

|

| Tipas | Butt Weld (BW) / Besiūliai / Welded / ERW / Fabricated |

| Coating / Surface Treatment | Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized |

Manufacturing Standards of Buttweld Reducing Cross

| ASME Standard | ASME/ANSI B16.9, ASME/ANSI B16.28, MSS-SP-43 |

| DIN Standard | DIN28011, DIN2617, DIN2616, DIN2615, DIN2605 |

| EN Standard | EN10253-2, EN10253-1 |

| ASME B16.25 | Buttwelding Ends |

| ASME B16.9 | Factory-Made Wrought Fittings Buttwelding |

| ASME B16.28 | Wrought Steel Unequal Cross |

| ASTM A403 – ASME SA403 | Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings |

| MSS SP-43 | Wrought & Fabricated Butt-Welding Fitting for Low Pres |

Dimensions of Reducing Cross

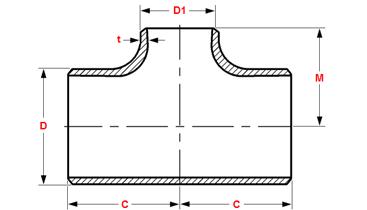

Stainless Steel Reducing Cross Stainless Steel Reducing Cross Drawing

| Nominal Diameter | Outside Diameter | Center to End | |||||

| D1 | D2 | ||||||

| DN | NPS | Series A | Series B | Series A | Series B | C | M |

| 150×90 | 6×3.1/2 | 168.3 | – | 101.6 | – | 143 | 127 |

| 150×80 | 6×3 | 168.3 | 159 | 88.9 | 89 | 143 | 124 |

| 150×65 | 6×2.1/2 | 168.3 | 159 | 73.0 | 76 | 143 | 121 |

| 200×200 | 8×8 | 219.1 | 219 | 219.1 | 219 | 178 | 178 |

| 200×150 | 8×6 | 219.1 | 219 | 168.3 | 159 | 178 | 168 |

| 200×125 | 8×5 | 219.1 | 219 | 141.4 | 133 | 178 | 162 |

| 200×100 | 8×4 | 219.1 | 219 | 114.3 | 108 | 178 | 156 |

| 200×90 | 8×3.1/2 | 219.1 | – | 101.6 | – | 178 | 152 |

| 250×250 | 10×10 | 273.0 | 273 | 273.0 | 273 | 216 | 216 |

| 250×200 | 10×8 | 273.0 | 273 | 219.1 | 219 | 216 | 203 |

| 250×150 | 10×6 | 273.0 | 273 | 168.3 | 159 | 216 | 194 |

| 250×125 | 10×5 | 273.0 | 273 | 141.3 | 133 | 216 | 191 |

| 250×100 | 10×4 | 273.0 | 273 | 114.3 | 108 | 216 | 184 |

| 300×300 | 12×12 | 323.9 | 325 | 323.9 | 325 | 254 | 254 |

| 300×250 | 12×10 | 323.9 | 325 | 273.0 | 273 | 254 | 241 |

| 300×200 | 12×8 | 323.9 | 325 | 219.1 | 219 | 254 | 229 |

| 300×150 | 12×6 | 323.9 | 325 | 168.3 | 159 | 254 | 219 |

| 300×125 | 12×5 | 323.9 | 325 | 141.3 | 133 | 254 | 216 |

| 350×350 | 14×14 | 355.6 | 377 | 355.6 | 377 | 279 | 279 |

| 350×300 | 14×12 | 355.6 | 377 | 323.9 | 325 | 279 | 270 |

| 350×250 | 14×10 | 355.6 | 377 | 273.0 | 273 | 279 | 257 |

| 350×200 | 14×8 | 355.6 | 377 | 219.1 | 219 | 279 | 248 |

| 350×150 | 14×6 | 355.6 | 377 | 168.3 | 159 | 279 | 238 |

| 400×400 | 16×16 | 406.4 | 426 | 406.4 | 426 | 305 | 305 |

| 400×350 | 16×14 | 406.4 | 426 | 355.6 | 377 | 305 | 305 |

| 400×300 | 16×12 | 406.4 | 426 | 323.9 | 325 | 305 | 295 |

| 400×250 | 16×10 | 406.4 | 426 | 273.0 | 273 | 305 | 283 |

| 400×200 | 16×8 | 406.4 | 426 | 219.1 | 219 | 305 | 273 |

| 400×150 | 16×6 | 406.4 | 426 | 168.3 | 159 | 305 | 264 |

| 450×450 | 18×18 | 457 | 480 | 457 | 480 | 343 | 343 |

| 450×400 | 18×16 | 457 | 480 | 406.4 | 426 | 343 | 330 |

| 450×350 | 18×14 | 457 | 480 | 355.6 | 377 | 343 | 330 |

| 450×300 | 18×12 | 457 | 480 | 323.9 | 325 | 343 | 321 |

| 450×250 | 18×10 | 457 | 480 | 273.0 | 273 | 343 | 308 |

| 15×15 | 1/2×1/2 | 21.3 | 18 | 21.3 | 18 | 25 | 25 |

| 15×10 | 1/2×3/8 | 21.3 | 18 | 17.3 | 14 | 25 | 25 |

| 15×8 | 1/2×1/4 | 21.3 | 18 | 13.7 | 10 | 25 | 25 |

| 20×20 | 3/4×3/4 | 26.9 | 25 | 26.9 | 25 | 29 | 29 |

| 20×15 | 3/4×1/2 | 26.9 | 25 | 21.3 | 18 | 29 | 29 |

| 20×10 | 3/4×3/8 | 26.9 | 25 | 17.3 | 14 | 29 | 29 |

| 25×25 | 1×1 | 33.7 | 32 | 33.7 | 32 | 38 | 38 |

| 25×20 | 1×3/4 | 33.7 | 32 | 26.9 | 25 | 38 | 38 |

| 25×15 | 1×1/2 | 33.7 | 32 | 21.3 | 18 | 38 | 38 |

| 32×32 | 1.1/4×1.1/4 | 42.4 | 38 | 42.4 | 38 | 48 | 48 |

| 32×25 | 1.1/4×1 | 42.4 | 38 | 33.7 | 32 | 48 | 48 |

| 32×20 | 1.1/4×3/4 | 42.4 | 38 | 26.9 | 25 | 48 | 48 |

| 32×15 | 1.1/4×1/2 | 42.4 | 38 | 21.3 | 18 | 48 | 48 |

| 40×40 | 1.1/2×1.1/2 | 48.3 | 45 | 48.3 | 45 | 57 | 57 |

| 40×32 | 1.1/2×1.1/4 | 48.3 | 45 | 42.4 | 38 | 57 | 57 |

| 40×25 | 1.1/2×1 | 48.3 | 45 | 33.7 | 32 | 57 | 57 |

| 40×20 | 1.1/2×3/4 | 48.3 | 45 | 26.9 | 25 | 57 | 57 |

| 40×15 | 1.1/2×1/2 | 48.3 | 45 | 21.3 | 18 | 57 | 57 |

| 50×50 | 2×2 | 60.3 | 57 | 60.3 | 57 | 64 | 64 |

| 50×40 | 2×1.1/2 | 60.3 | 57 | 48.3 | 45 | 64 | 60 |

| 50×32 | 2×1.1/4 | 60.3 | 57 | 42.4 | 38 | 64 | 57 |

| 50×25 | 2×1 | 60.3 | 57 | 33.7 | 32 | 64 | 51 |

| 50×20 | 2×3/4 | 60.3 | 57 | 26.9 | 25 | 64 | 44 |

| 65×65 | 2/1/2×2.1/2 | 73.0 | 76 | 73.0 | 76 | 76 | 76 |

| 65×50 | 2/1/2×2 | 73.0 | 76 | 60.3 | 57 | 76 | 70 |

| 65×40 | 2/1/2×1.1/2 | 73.0 | 76 | 48.3 | 45 | 76 | 67 |

| 65×32 | 2/1/2×1.1/4 | 73.0 | 76 | 42.4 | 38 | 76 | 64 |

| 65×25 | 2/1/2×1 | 73.0 | 76 | 33.7 | 32 | 76 | 57 |

| 80×80 | 3×3 | 88.9 | 89 | 88.9 | 89 | 86 | 86 |

| 80×65 | 3×2.1/2 | 88.9 | 89 | 73.0 | 76 | 86 | 83 |

| 80×50 | 3×2 | 88.9 | 89 | 60.3 | 57 | 86 | 76 |

| 80×40 | 3×1.1/2 | 88.9 | 89 | 48.3 | 45 | 86 | 73 |

| 80×32 | 3×1.1/4 | 88.9 | 89 | 42.4 | 38 | 86 | 70 |

| 90×90 | 3.1/2×3.1/2 | 101.6 | – | 101.6 | – | 95 | 95 |

| 90×80 | 3.1/2×3 | 101.6 | – | 88.9 | 89 | 95 | 92 |

| 90×65 | 3.1/2×2.1/2 | 101.6 | – | 73.0 | 76 | 95 | 89 |

| 90×50 | 3.1/2×2 | 101.6 | – | 60.3 | 57 | 95 | 83 |

| 90×40 | 3.1/2×1.1/2 | 101.6 | – | 48.3 | 45 | 95 | 79 |

| 100×100 | 4×4 | 114.3 | 108 | 114.3 | 108 | 105 | 105 |

| 100×90 | 4×3.1/2 | 114.3 | 108 | 101.6 | – | 105 | 102 |

| 100×80 | 4×3 | 114.3 | 108 | 88.9 | 89 | 105 | 98 |

| 100×65 | 4×2.1/2 | 114.3 | 108 | 73.0 | 76 | 105 | 95 |

| 100×50 | 4×2 | 114.3 | 108 | 60.3 | 57 | 105 | 89 |

| 100×40 | 4×1.1/2 | 114.3 | 108 | 48.3 | 45 | 105 | 86 |

| 125×125 | 5×5 | 141.3 | 133 | 141.3 | 133 | 124 | 124 |

| 125×100 | 5×4 | 141.3 | 133 | 114.3 | 108 | 124 | 117 |

| 125×90 | 5×3.1/2 | 141.3 | – | 101.6 | – | 124 | 114 |

| 125×80 | 5×3 | 141.3 | 133 | 88.9 | 89 | 124 | 111 |

| 125×65 | 5×2.1.2 | 141.3 | 133 | 73.0 | 76 | 124 | 108 |

| 125×50 | 5×2 | 141.3 | 133 | 60.3 | 57 | 124 | 105 |

| 150×150 | 6×6 | 168.3 | 159 | 168.3 | 159 | 143 | 143 |

| 150×125 | 6×5 | 168.3 | 159 | 141.3 | 133 | 143 | 137 |

| 150×100 | 6×4 | 168.3 | 159 | 114.3 | 108 | 143 | 130 |

| 450×200 | 18×8 | 457 | 480 | 219.1 | 219 | 343 | 298 |

| 500×500 | 20×20 | 508 | 530 | 508 | 530 | 381 | 381 |

| 500×450 | 20×20 | 508 | 530 | 457 | 480 | 381 | 368 |

| 500×400 | 20×20 | 508 | 530 | 406.4 | 426 | 381 | 356 |

| 500×350 | 20×20 | 508 | 530 | 355.6 | 377 | 381 | 356 |

| 500×300 | 20×20 | 508 | 530 | 323.9 | 325 | 381 | 346 |

| 500×250 | 20×20 | 508 | 530 | 273.0 | 273 | 381 | 333 |

| 500×200 | 20×20 | 508 | 530 | 219.1 | 219 | 381 | 324 |

ASME B16.9 Reducing Cross Dimensional Tolerance

| Nominal Pipe Size | 1/2 to 2½ | 3 to 3½ | 4 | 5 į 8 |

| Outside Diameter at Bevel (D) |

+ 1.6 – 0.8 |

1.6 | 1.6 | + 2.4 – 1.6 |

| Inside Diameter at End | 0.8 | 1.6 | 1.6 | 1.6 |

| Center to End LR (A/B) | 2 | 2 | 2 | 2 |

| Center to End 3D (A/B) | 3 | 3 | 3 | 3 |

| Nominal Pipe Size | 10 į 18 | 20 į 24 | 26 į 30 | 32 į 48 |

| Outside Diameter at Bevel (D) |

+ 4 – 3.2 |

+ 6.4 – 4.8 |

+ 6.4 – 4.8 |

+ 6.4 – 4.8 |

| Inside Diameter at End | 3.2 | 4.8 | + 6.4 – 4.8 |

+ 6.4 – 4.8 |

| Center to End LR (A/B) | 2 | 2 | 3 | 5 |

| Center to End 3D (A/B) | 3 | 3 | 6 | 6 |

| Wall Thickness (t) | Not less than 87.5% of Nominal Wall Thickness | |||

ASME B16.9 Buttweld Reducing Cross Weight Chart

| Nominal pipe size in | SCH 10 | SCH 20 | SCH 30 | SCH 40 | ||||||||

| wall thk mm | weight kg | weight kg | wall thk mm | weight kg | weight kg | wall thk mm | weight kg | weight kg | wall thk mm | weight kg | weight kg | |

| T | T | T | T | |||||||||

| 1″ | 3.38 | 0.34 | ||||||||||

| 1.1/4″ | 3.68 | 0.92 | ||||||||||

| 1/2″ | 2.77 | 0.21 | ||||||||||

| 3/4″ | 2.87 | 0.21 | ||||||||||

| 1.1/2″ | 3.56 | 0.63 | ||||||||||

| 2″ | 3.91 | 1.49 | ||||||||||

| 2.1/2″ | 5.16 | 2.68 | ||||||||||

| 3″ | 5.49 | 3.75 | ||||||||||

| 3.1/2″ | 5.74 | 5 | ||||||||||

| 4″ | 6.02 | 6.5 | ||||||||||

| 5″ | 6.55 | 10 | ||||||||||

| 6″ | 7.11 | 16 | ||||||||||

| 8″ | 6.35 | 23 | 7.04 | 24.6 | 8.18 | 27 | ||||||

| 10″ | 6.35 | 34.7 | 7.8 | 40 | 9.27 | 41 | ||||||

| 12″ | 6.35 | 43.4 | 8.38 | 56.6 | 10.31 | 70.5 | ||||||

| 14″ | 6.35 | 68 | 7.92 | 84 | 9.53 | 102 | 11.13 | 105 | ||||

| 16″ | 6.35 | 90.8 | 7.92 | 100 | 9.53 | 110 | 12.7 | 167 | ||||

| 18″ | 6.35 | 93.1 | 9.53 | 127 | 11.13 | 164 | 14.27 | 237.45 | ||||

| 20″ | 6.35 | 112 | 9.53 | 168 | 12.7 | 245 | 15.09 | 320 | ||||

| 22″ | 6.35 | 146 | 9.53 | 220 | 12.7 | 280 | ||||||

| 24″ | 6.35 | 160 | 12.7 | 240 | 14.27 | 373 | 17.48 | 570.65 | ||||

| 26″ | 7.92 | 293.28 | 12.7 | 360.2 | ||||||||

| 28″ | 7.92 | 280.98 | 12.7 | 421 | 15.88 | 526.25 | ||||||

| 30″ | 7.92 | 322.64 | 12.7 | 483.1 | 15.88 | 603.75 | ||||||

| 32″ | 7.92 | 375.23 | 12.7 | 559 | 15.88 | 698.75 | 17.48 | 768.6 | ||||

| 34″ | 7.92 | 482.72 | 12.7 | 644.1 | 15.88 | 805.13 | 17.48 | 885.65 | ||||

| 36″ | 7.92 | 488.3 | 12.7 | 730.3 | 15.88 | 912.88 | 19.05 | 1004.17 | ||||

ASME B16.9 SS Reducing Cross Angularity Tolerance

| ND | Max off angle | Max off plane |

| Q | P | |

| 1/2 a 4 | 1 | 2 |

| 5 a 8 | 2 | 4 |

| 10 a 12 | 3 | 5 |

| 14 a 16 | 3 | 7 |

| 18 a 24 | 4 | 10 |

| 26 a 30 | 5 | 10 |

| 32 a 42 | 5 | 13 |

| 44 a 48 | 5 | 20 |

BUTTWELD REDUCING CROSS – MATERIALS & GRADES

| Stainless Steel Buttweld Reducing / Unequal Cross | ASTM A403 WP316/316L, ASTM A403 SA / A 774 WP-S, WP-W, WP-WX 304/304L, ASTM A182 F316L, 304L, NUO 1.4301, DIN1.4306, NUO 1.4401, NUO 1.4404 |

| Dvipusis & Super Duplex Steel Buttweld Reducing / Unequal Cross | ASTM A 815, ASME SA 815 UNS NO S31803, S32205. US S32750, S32950. Werkstoff No. 1.4462 |

| Carbon Steel Buttweld Reducing / Unequal Cross | ASTM A234, ASME SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

| Low Temperature Carbon Steel Buttweld Reducing / Unequal Cross | ASTM A420 WPL3, A420 WPL6 |

| Alloy Steel Buttweld Reducing / Unequal Cross | ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

| Nickel Alloy Buttweld Reducing / Unequal Cross | ASTM B336, ASME SB336, Nickel 200 (UNS No. No2200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Lydinys 20 (UNS No. N08020), Titanium (Grade I & II), Cupro-Nickel 70/30, CuNi10Fe1Mn, CuNi30Mn1Fe. |

Available Types of ASME B16.9 Buttweld Reducing Cross

| ANSI B16.9 Buttweld Reducing Cross | ASME B16.28 Buttweld Pipe Cross |

| Welded Butt weld Unequal Cross | Seamless Butt weld Unequal Cross |

| Carbon Steel Reducing Cross | High Quality Unequal Cross |

| ASTM A403 Stainless Steel Unequal Crosss | Duplex Steel Buttweld Reducing Cross |

| Buttweld Unequal Cross | Butt Weld Reducing Crosss |

| ASME B16.9 Butt weld Unequal Cross | Steel Reducing Cross Pipe Fittings |

| Stainless Steel Unequal Cross | SS Unequal Crosss |

| Super Duplex Steel Buttweld Reducing Cross | Copper Nickel Unequal Cross |

| High Nickel Alloy Unequal Cross | Hastelloy Pipe Cross |

| Titanium Buttweld Reducing Cross | Inconel Butt weld Reducing Cross |

Buttweld Reducing Cross Application

ASME B16.9 Unequal Cross are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a broad range of Buttweld Reducing Cross through a worldwide network of stock-keeping branches. These Unequal Pipe Cross is use in various industries like :

- Stainless Steel Buttweld Unequal Cross uses in Oil and Gas Pipeline

- Butt weld Unequal Cross uses in Chemical Industry

- Alloy Steel Unequal Cross uses in Plumbing

- Buttweld Pipe Reducing Cross uses in Heating

- Buttweld Unequal Cross Fittings uses in Water Supply Systems

- ANSI B16.9 Buttweld Unequal Cross uses in Power Plant

- Buttweld Unequal Cross Fitting uses in Paper & Pulp Industry

- Unequal Cross uses in General Purpose Applications

- Buttweld Reducing Cross uses in Fabrication Industry

- Unequal Cross uses in Food Processing Industry

- Buttweld Unequal Cross uses in Structural Pipe

Nerūdijančio plieno vamzdžių tiekėjas Wenzhou Kaixin Kinija

Nerūdijančio plieno vamzdžių tiekėjas Wenzhou Kaixin Kinija