A butt weld 45 degree long radius elbow is a type of pipe fitting that is used to change the direction of the flow in a piping system by 45 degrees. It is designed with a long radius, which means that the curvature of the elbow is relatively gentle, allowing for a smoother flow of fluid through the system. Butt weld 45 degree long radius elbows are made by welding two pipes or tubes together at a 45 degree angle, with the weld seam being flush with the surface of the elbow. They are commonly used in industries such as oil and gas, petrochemicals, and power generation to connect pipes and redirect the flow of fluids around obstacles or through corners.

Butt weld Fitting 45° Long Radius Elbow Specification

| Paerewa | ANSI/ASME :ASTM A403 / ASME SA403, ANSI B16.9, ASME B16.25, ASME B16.28, MSS SP-43.

MAI : DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 IN : EN10253-1, EN10253-2 |

| Schedule | Apiti 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS me etahi atu. |

| Rahi | Seamless 45° Long Radius Elbow Size: 1/2″~24″

EKA / He paiherea / Fabricated 45° Long Radius Elbow Size: 1/2″ (15 NB) to 48″ (1200NB) |

| Koeke | 304/L/H/LN, 316/L/H/LN/Ti, 321/H, 317/L/LN, 347/H, 310S/H, N08904(904L), S31803,S32205, S32750, S32760, N02200, N02201, N04400, N06600, N06690, N06625, N06985(G3), N08028, N08800, N08810, N08811, N08825Surface |

| Momo | Butt Weld (BW) / He paiherea / EKA / Hangaia |

| Ahu | ANSI B16.9, ANSI B16.28, MSS-SP-43 Momo A, MSS-SP-43 Momo B, |

Butt weld Fitting 45° Long Radius Elbow MATERIAL & KOEKE

| Stainless Steel Buttweld 45 Waeine Roa Rorohiko Tuke | ASTM A403 WP316/316L, ASTM A403 SA / A 774 WP-S, WP-W, WP-WX 304/304L, ASTM A182 F316L, 304L, MAI 1.4301, DIN1.4306, MAI 1.4401, MAI 1.4404 |

| Duplex & Super Duplex Steel Buttweld 45 Waeine Roa Rorohiko Tuke | ASTM A 815, ASME SA 815 UNS NO S31803, S32205. UNS S32750, S32950. Werkstoff No. 1.4462 |

| Carbon Steel Buttweld 45 Waeine Roa Rorohiko Tuke | ASTM A234, ASME SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

| Low Temperature Carbon Steel 45 Waeine Roa Rorohiko Tuke | ASTM A420 WPL3, A420 WPL6 |

| Alloy Steel Buttweld 45 Waeine Roa Rorohiko Tuke | ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

| Nickel Alloy Buttweld 45 Waeine Roa Rorohiko Tuke | ASTM B336, ASME SB336, Nickel 200 (UNS No. Kao2200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Kohanga 20 (UNS No. N08020), Titanium (Kōeke I & II), Cupro-Nikeli 70/30, CuNi10Fe1Mn, CuNi30Mn1Fe. |

Applications of 45 DEGREE LONG RADIUS ELBOW

- Stainless Steel 45° Long Radius Elbow uses in Oil and Gas Pipeline

- 45° Buttweld LR Elbow uses in Chemical Industry

- Alloy Steel 45° Long Radius Elbow uses in Plumbing

- 45° Long Radius Elbow Pipe Fittings uses in Food Processing Industry

- Buttweld 45° LR Elbow uses in Structural Pipe

- ANSI B16.9 Buttweld 45° Long Radius Elbow uses in Power Plant

- 45° Long Radius Pipe Elbow uses in Paper & Pulp Industry

- 45 Deg Long Radius Bend uses in Heating

- 45 Degree Long Radius Reducing Elbow uses in Water Supply Systems

- ASME B16.9 Long Radius 45 Deg Elbow uses in General Purpose Applications

- 45° LR Elbow uses in Fabrication Industry

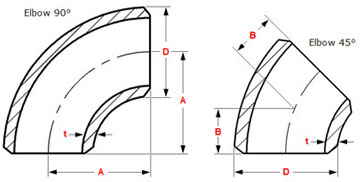

45 Deg Long Radius Elbow Ahu

Paarua 45 Degree Long Radius Elbow Dimension Drawing

| NPS | O.D.

D |

90 degrees

Long Radius Center-to-End A |

45 degrees

Long Radius Center-to-End B |

90 degrees

3D Center-to-End A |

45 degrees

3D Center-to-End B |

| 1/2 | 21.3 | 38 | 16 | – | – |

| 3/4 | 26.7 | 38 | 19 | 57 | 24 |

| 1 | 33.4 | 38 | 22 | 76 | 31 |

| 1 ¼ | 42.2 | 48 | 25 | 95 | 39 |

| 1 ½ | 48.3 | 57 | 29 | 114 | 47 |

| 2 | 60.3 | 76 | 35 | 152 | 63 |

| 2 ½ | 73 | 95 | 44 | 190 | 79 |

| 3 | 88.9 | 114 | 51 | 229 | 95 |

| 3 ½ | 101.6 | 133 | 57 | 267 | 111 |

| 4 | 114.3 | 152 | 64 | 305 | 127 |

| 5 | 141.3 | 190 | 79 | 381 | 157 |

| 6 | 168.3 | 229 | 95 | 457 | 189 |

| 8 | 219.1 | 305 | 127 | 610 | 252 |

| 10 | 273 | 381 | 159 | 762 | 316 |

| 12 | 323.8 | 457 | 190 | 914 | 378 |

| 14 | 355.6 | 533 | 222 | 1067 | 441 |

| 16 | 406.4 | 610 | 254 | 1219 | 505 |

| 18 | 457 | 686 | 286 | 1372 | 568 |

| 20 | 508 | 762 | 318 | 1524 | 632 |

| 22 | 559 | 838 | 343 | 1676 | 694 |

| 24 | 610 | 914 | 381 | 1829 | 757 |

| 26 | 660 | 991 | 406 | 1981 | 821 |

| 28 | 711 | 1067 | 438 | 2134 | 883 |

| 30 | 762 | 1143 | 470 | 2286 | 964 |

| 32 | 813 | 1219 | 502 | 2438 | 1010 |

| 34 | 864 | 1295 | 533 | 2591 | 1073 |

| 36 | 914 | 1372 | 565 | 2743 | 1135 |

| 38 | 965 | 1448 | 600 | 2896 | 1200 |

| 40 | 1016 | 1524 | 632 | 3048 | 1264 |

| 42 | 1067 | 1600 | 660 | 3200 | 1326 |

| 44 | 1118 | 1676 | 695 | 3353 | 1389 |

| 46 | 1168 | 1753 | 727 | 3505 | 1453 |

| 48 | 1219 | 1829 | 759 | 3658 | 1516 |

DIMENSIONAL TOLERANCES OF 45 DEGREE LONG RADIUS ELBOW – ASME B16.9

| DIMENSIONAL TOLERANCES – ELBOWS | |||||||

| For all fittings | Elbows 90/45 deg | 180° Returns | |||||

| Rahi Paipa Ingoa (NPS) | Outside Ø

at Bevel |

Inside Ø

at End |

Matotoru pakitara

t / t1 |

Center to End Dim. A-B-C-M | Center to Center Dim.

O |

Back to Face Dim.

K |

Align- ment of Ends

U |

| 1/2 a 2 1/2 | 1 | 0,8 | Kaore | 2 | 7 | 7 | 1 |

| 3 a 3 1/2 | 1 | 1,6 | iti iho | 2 | 7 | 7 | 1 |

| 4 | +2 -1 | 1,6 | atu | 2 | 7 | 7 | 1 |

| 5 a 6 | +3 -1 | 1,6 | 87,50% | 2 | 7 | 7 | 1 |

| 8 | 2 | 1,6 | o nominal | 2 | 7 | 7 | 1 |

| 10 | +4 -3 | 3,2 | whakatiki | 2 | 7 | 7 | 2 |

| 12 a 18 | +4 -3 | 3,2 | 3 | 10 | 7 | 2 | |

| 20 a 24 | +6 -5 | 4,8 | 3 | 10 | 7 | 2 | |

| 26 a 30 | +7 -5 | 4,8 | 3 | ….. | ….. | ….. | |

| 32 a 48 | +7 -5 | 4,8 | 5 | ….. | ….. | ….. | |

ANGULARITY TOLERANCES OF 45 DEGREE LONG RADIUS ELBOW

| Angularity Tolerances | ||

| ND | Max atu koki | Max atu i te rererangi |

| Q | P | |

| 1/2 a 4 | 1 | 2 |

| 5 a 8 | 2 | 4 |

| 10 a 12 | 3 | 5 |

| 14 a 16 | 3 | 7 |

| 18 a 24 | 4 | 10 |

| 26 a 30 | 5 | 10 |

| 32 a 42 | 5 | 13 |

| 44 a 48 | 5 | 20 |

AVAILABLE TYPES OF 45 DEGREE LONG RADIUS ELBOW

| Buttweld 45° Long Radius Elbow | Duplex Steel Buttweld 45° Long Radius Elbow |

| ASME B16.9 Butt weld 45° Long Radius Elbow | High Nickel Alloy 45° Long Radius Elbow |

| Stainless Steel 45° Long Radius Elbow | SS 45° Long Radius Elbow |

| High Quality 45° Long Radius Elbow | Seamless Butt weld 45° Long Radius Elbow |

| Welded Butt weld 45° Long Radius Elbowr | ASME B16.28 Buttweld 45° Long Radius Elbow |

| Carbon Steel 45° Long Radius Elbow | ANSI B16.9 Buttweld 45° Long Radius Elbow |

| Titanium Buttweld 45° Long Radius Elbow | Inconel Butt weld 45° Long Radius Elbow |

| ASTM A403 Stainless Steel 45° Long Radius Elbow | Butt Weld B16.9 45° Long Radius Elbow |

| Super Duplex Steel Buttweld 45° Long Radius Elbow | Copper Nickel 45° Long Radius Elbow |

| Steel 45° Long Radius Elbow | Hastelloy 45° Long Radius Elbow |

WEIGHT OF 45 Deg Long Radius Elbow

Buttweld Elbow Weight in LBS and KG

| Type-> | SCHEDULE STD | SCHEDULE XS |

| NPS | LBS | KG | LBS | KG |

| 1/2 | 0.09 | 0.04 | 0.19 | 0.09 |

| 3/4 | 0.09 | 0.04 | 0.19 | 0.09 |

| 1 | 0.25 | 0.11 | 0.31 | 0.14 |

| 1 ¼ | 0.38 | 0.17 | 0.5 | 0.23 |

| 1 ½ | 0.4 | 0.18 | 0.69 | 0.31 |

| 2 | 0.81 | 0.37 | 1.19 | 0.54 |

| 2 ½ | 1.75 | 0.79 | 2.13 | 0.97 |

| 3 | 2.63 | 1.19 | 3.5 | 1.59 |

| 3 ½ | 3.5 | 1.59 | 4.5 | 2.04 |

| 4 | 4.5 | 2.04 | 6.1 | 2.77 |

| 5 | 7.5 | 3.4 | 10.7 | 4.85 |

| 6 | 12 | 5.44 | 17.5 | 7.94 |

| 8 | 23 | 10.43 | 35 | 15.88 |

| 10 | 43 | 19.5 | 53 | 24.04 |

| 12 | 62 | 28.12 | 84 | 38.1 |

| 14 | 80 | 36.29 | 100 | 45.36 |

| 16 | 100 | 45.36 | 135 | 61.23 |

| 18 | 126 | 57.15 | 167 | 75.75 |

| 20 | 160 | 72.57 | 206 | 93.44 |

| 22 | 197 | 89.36 | 260 | 117.93 |

| 24 | 238 | 107.95 | 300 | 136.08 |

| 26 | 275 | 124.74 | 365 | 165.56 |

| 30 | 367 | 166.47 | 488 | 221.35 |

| 36 | 531 | 240.86 | 706 | 320.24 |

45 Degree Elbow Cutting Formula

- R1 = elbow radius marking 1

- R2 = elbow radius marking 2

- R3 = elbow radius marking 3

EC = Elbow Center

OD = Outside Daimeter

R2 = Both Side Radius Marking

45 Degree Elbow Take Off Formula

(R1) – tan x 1 x (EC – 1/2 OD) x Deg = answar

(R2) – tan x 1 x EC … x Deg = answar

(R3) – tan x 1 (EC + 1/2 OD) x deg = answar

Kowiri tira Pipa Kaiwhakarato Wenzhou Kaixin Haina

Kowiri tira Pipa Kaiwhakarato Wenzhou Kaixin Haina