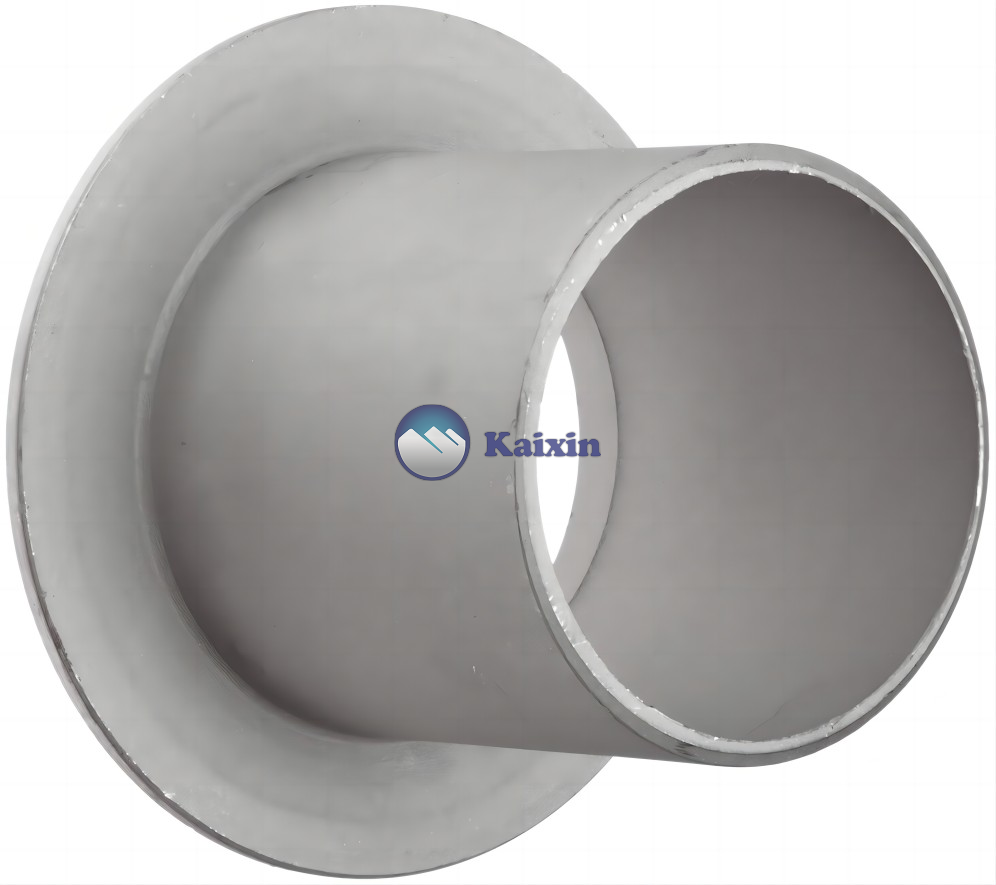

A stainless steel long stub end is a type of fitting used in piping systems to connect two sections of pipe or tubing. The long stub end is typically used in applications where the piping system needs to be easily disassembled or in situations where the pipe needs to be cut and reconnected at a later time.

Stainless steel is a popular material for long stub ends because it is corrosion-resistant, durable, and can withstand high temperatures and pressures. This makes it suitable for use in a variety of industries, including chemical processing, oil and gas, and food and beverage.

The design of a stainless steel long stub end consists of a short length of pipe with a flange on one end and a buttweld connection on the other end. The flange allows the stub end to be bolted to a corresponding flange on the pipe or equipment being connected. The buttweld connection is used to weld the stub end to the pipe or tubing that needs to be connected.

Overall, a stainless steel long stub end is an essential component of many piping systems and is used to ensure reliable and efficient operation.

Standard Specification For Buttweld Long Stub End

| Rahi | 1/2” TO 36”, (Seamless up to 24”), (Welded 8” TO 36”) |

| Paerewa | ANSI/ASME :ASTM A403 / ASME SA403, ANSI B16.9, ASME B16.25, ASME B16.28, MSS SP-43.DIN : DIN2605, DIN2615, DIN2616, DIN2617, DIN28011,IN : EN10253-1, EN10253-2 |

| Ahu | ASME/ANSI B16.9, MSS-SP-43 Momo A, MSS-SP-43 Momo B, JIS B2312, JIS B2313, ASME B16.28 |

| Mātotoru | Apiti 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS me etahi atu. |

| Bending Radius | R=1D – 10D, 15D, 20D |

| Mai | Long Stub Ends, Pipe Stub Ends, Butt weld Long Stub Ends. |

| Koeke&Rauemi | ASTM A403 WP316/316L, ASTM A403 SA / A 774 WP-S, WP-W, WP-WX 304/304L, ASTM A182 F316L, 304L, MAI 1.4301, DIN1.4306, MAI 1.4401, MAI 1.4404,ASTM A 815, ASME SA 815 UNS NO S31803, S32205. UNS S32750, S32950. Werkstoff No. 1.4462,ASTM A234, ASME SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.ASTM A420 WPL3, A420 WPL6,ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91,ASTM B336, ASME SB336, Nickel 200 (UNS No. Kao2200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Kohanga 20 (UNS No. N08020), Titanium (Kōeke I & II), Cupro-Nikeli 70/30, CuNi10Fe1Mn, CuNi30Mn1Fe. |

| Momo | Tuhia / EKA / He paiherea / Hangaia |

| Surface Coatings | Epoxy Coated, Black Painted, Varnished, Galvanized.Connection |

| Connection Type | End Bell / Threaded/ Clamp End / Weld/ Flange/ |

Butt Weld Long Stub End Manufacturing Standards

| ASME Paerewa | ASME/ANSI B16.9, ASME/ANSI B16.28, MSS-SP-43 |

| DIN Paerewa | DIN28011, DIN2617, DIN2616, DIN2615, DIN2605 |

| He Paerewa | EN10253-2, EN10253-1 |

| ASME B16.25 | Ka mutu te weranga |

| ASME B16.9 | Ko nga taputapu Raina i hangaia e te wheketere |

| ASME B16.28 | Wrought Steel Eccentric Reducer |

| ASTM A403 – ASME SA403 | Standard Specification for Wrought Austenitic Stainless Steel Piping Fitting |

| MSS SP-43 | Mahi & Hangaia te Reke-Welding Fiting mo te Peetanga Iti, Corrosion Resistant Applications |

Long Stub End Materials and Grades

| Stainless Steel Buttweld Long Stub End | ASTM A403 WP316/316L, ASTM A403 SA / A 774 WP-S, WP-W, WP-WX 304/304L, ASTM A182 F316L, 304L, MAI 1.4301, DIN1.4306, MAI 1.4401, MAI 1.4404 |

| Duplex & Super Duplex Steel Buttweld Long Stub End | ASTM A 815, ASME SA 815 UNS NO S31803, S32205. UNS S32750, S32950. Werkstoff No. 1.4462 |

| Carbon Steel Buttweld Long Stub End | ASTM A234, ASME SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

| Low Temperature Carbon Steel Buttweld Long Stub End | ASTM A420 WPL3, A420 WPL6 |

| Alloy Steel Buttweld Long Stub End | ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

| Nickel Alloy Buttweld Long Stub End | ASTM B336, ASME SB336, Nickel 200 (UNS No. Kao2200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Kohanga 20 (UNS No. N08020), Titanium (Kōeke I & II), Cupro-Nikeli 70/30, CuNi10Fe1Mn, CuNi30Mn1Fe. |

Long Stub End Types

Long Stub End are offered in three different ways, Type A, B and C. Type A and B stub end are similar to forged fittings, such as elbows and tees, and type C stub end are made in customized sizes.

Type A

The Type A Long Stub End is employed for standard joint flange. The lap thickness on the stub end is bigger than or up to the nominal thickness of pipe wall. Additionally, the outer corner radius of the sort A will receive the Long flange. The within corner is square. Lap sometimes includes a machined rough face.

Type B

The Type B Long Stub End is employed for standard slip on flanges as lap flanges. The lap thickness on these short ends is bigger than or up to the nominal thickness of pipe wall. Also, the outer corner radius of type B is tiny enough to receive the slip o flange which will be used as a backup flange. The inner corner is square. Long Stub End sometimes includes a machined rough face.

Type C

The Type C Long Stub End will be used for standard Long flange, and put on flange. It’s flaring feat a rounded edge at the within diameter of the lap. Mena e tika ana, the radius will be created closed to a square. The lap thickness is 75th of the pipe wall. The sort C is very short enough to accommodate any backup flange. The Long Stub End on kind C is smooth, and it’s not machined.

Long Stub End Dimensions

| Hua | Nom. Pipe Size | Dia (G) | Length (F), Short | Outside Dia (O.D.) | Sch 160, Inside Dia (I.D.) | Sch 160, Lap Thickness (t) | Schedule 160, Matotoru pakitara (T) | XX Strong Wall Approx. Weight | XX Strong Wall, Inside Dia (I.D.) |

| 1 1/2″ Stub Ends Long Type “A | 1.5 | 2.875 | 2 | 1.9 | 1.338 | 0.281 | 0.281 | 2.98 | 1.1 |

| 1 1/2″ Stub Ends Long Type “A” | 1.5 | 2.875 | 4 | 1.9 | 0.15 | 0.15 | 1.49 | 1.5 | 0.2 |

| 1 1/4″ Stub Ends Long Type “A | 1.25 | 2.5 | 2 | 1.66 | 1.16 | 0.25 | 0.25 | 2.52 | 0.896 |

| 1 1/4″ Stub Ends Long Type “A” | 1.25 | 2.5 | 4 | 1.66 | 0.14 | 0.14 | 1.26 | 1.278 | 0.191 |

| 1″ Stub Ends Long Type “A | 1 | 2 | 2 | 1.315 | 0.815 | 0.25 | 0.25 | 1.76 | 0.599 |

| 1″ Stub Ends Long Type “A” | 1 | 2 | 4 | 1.315 | 0.133 | 0.133 | 0.88 | 0.957 | 0.179 |

| 1/2″ Stub Ends Long Type “A | 0.5 | 1.375 | 2 | 0.84 | 0.464 | 0.187 | 0.188 | 0.68 | 0.252 |

| 1/2″ Stub Ends Long Type “A” | 0.5 | 1.375 | 3 | 0.84 | 0.109 | 0.109 | 0.34 | 0.546 | 0.147 |

| 10″ Stub Ends Long Type “A | 10 | 12.75 | 5 | 10.75 | 8.5 | 1.125 | 1.125 | – | – |

| 10″ Stub Ends Long Type “A” | 10 | 12.75 | 10 | 10.75 | 0.365 | 0.365 | 54 | 9.75 | 0.5 |

| 12″ Stub Ends Long Type “A | 12 | 15 | 6 | 12.75 | 10.126 | 1.312 | 1.312 | – | – |

| 12″ Stub Ends Long Type “A” | 12 | 15 | 10 | 12.75 | 0.375 | 0.375 | 64.5 | 11.75 | 0.5 |

| 14″ Stub Ends Long Type “A” | 14 | 16.25 | 12 | 14 | 0.375 | 0.375 | 84 | 13 | 0.5 |

| 16″ Stub Ends Long Type “A” | 16 | 18.5 | 12 | 16 | 0.375 | 0.375 | 98 | 15 | 0.5 |

| 18″ Stub Ends Long Type “A” | 18 | 21 | 12 | 18 | 0.375 | 0.375 | 136 | 17 | 0.5 |

| 2 1/2″ Stub Ends Long Type “A | 2.5 | 4.125 | 2.5 | 2.875 | 2.125 | 0.375 | 0.375 | 8.8 | 1.771 |

| 2 1/2″ Stub Ends Long Type “A” | 2.5 | 4.125 | 6 | 2.875 | 0.203 | 0.203 | 4.4 | 2.323 | 0.276 |

| 2″ Stub Ends Long Type “A | 2 | 3.625 | 2.5 | 2.375 | 1.689 | 0.343 | 0.343 | 6.1 | 1.503 |

| 2″ Stub Ends Long Type “A” | 2 | 3.625 | 6 | 2.375 | 0.154 | 0.154 | 3.05 | 1.939 | 0.218 |

| 20″ Stub Ends Long Type “A” | 20 | 23 | 12 | 20 | 0.375 | 0.375 | 157 | 19 | 0.5 |

| 3 1/2″ Stub Ends Long Type “A | 3.5 | 5.5 | 3 | 4 | – | – | – | 15.5 | 2.728 |

| 3 1/2″ Stub Ends Long Type “A” | 3.5 | 5.5 | 6 | 4 | 0.226 | 0.226 | 7.75 | 3.364 | 0.318 |

| 3″ Stub Ends Long Type “A | 3 | 5 | 2.5 | 3.5 | 2.624 | 0.438 | 0.438 | 9.8 | 2.3 |

| 3″ Stub Ends Long Type “A” | 3 | 5 | 6 | 3.5 | 0.216 | 0.216 | 6.5 | 2.9 | 0.3 |

| 3/4″ Stub Ends Long Type “A | 0.75 | 1.688 | 2 | 1.05 | 0.612 | 0.218 | 0.219 | 0.94 | 0.434 |

| 3/4″ Stub Ends Long Type “A” | 0.75 | 1.688 | 3 | 1.05 | 0.113 | 0.113 | 0.47 | 0.742 | 0.154 |

| 4″ Stub Ends Long Type “A | 4 | 6.188 | 3 | 4.5 | 3.438 | 0.531 | 0.531 | 19.3 | 3.152 |

| 4″ Stub Ends Long Type “A” | 4 | 6.188 | 6 | 4.5 | 0.237 | 0.237 | 9.65 | 3.826 | 0.337 |

| 5″ Stub Ends Long Type “A | 5 | 7.313 | 3 | 5.563 | 4.313 | 0.625 | 0.625 | 32.66 | 4.063 |

| 5″ Stub Ends Long Type “A” | 5 | 7.313 | 8 | 5.563 | 0.258 | 0.258 | 16.33 | 4.813 | 0.375 |

| 6″ Stub Ends Long Type “A | 6 | 8.5 | 3.5 | 6.625 | 5.187 | 0.718 | 0.719 | 45.26 | 4.897 |

| 6″ Stub Ends Long Type “A” | 6 | 8.5 | 8 | 6.625 | 0.28 | 0.28 | 22.63 | 5.761 | 0.432 |

| 8″ Stub Ends Long Type “A | 8 | 10.625 | 4 | 8.625 | 6.813 | 0.906 | 0.906 | 59.71 | 6.875 |

| 8″ Stub Ends Long Type “A” | 8 | 10.625 | 8 | 8.625 | 0.322 | 0.322 | 34.12 | 7.625 | 0.5 |

| STUB ENDS – ANSI B 16.9 and MSS SP-43 dimension | |||||||

| inihi | ND | mm | Diameter of lap | Radius of fillet | Length F | ||

| D | G | R | R1 | MSS SP43 | ANSI B16.9 | ||

| 1/2 | 15 | 21,34 | 34,92 | 3,17 | 0,80 | 50,80 | 76,20 |

| 3/4 | 20 | 26,67 | 42,86 | 3,17 | 0,80 | 50,80 | 76,20 |

| 1 | 25 | 33,40 | 50,80 | 3,17 | 0,80 | 50,80 | 101,60 |

| 1 1/4 | 32 | 42,16 | 63,50 | 4,76 | 0,80 | 50,80 | 101,60 |

| 1 1/2 | 40 | 48,26 | 73,00 | 6,35 | 0,80 | 50,80 | 101,60 |

| 2 | 50 | 60,32 | 92,10 | 7,93 | 0,80 | 63,50 | 152,40 |

| 2 1/2 | 65 | 73,02 | 104,80 | 7,93 | 0,80 | 63,50 | 152,40 |

| 3 | 80 | 88,90 | 127,00 | 9,52 | 0,80 | 63,50 | 152,40 |

| 3 1/2 | 90 | 101,60 | 139,70 | 9,52 | 0,80 | 76,20 | 152,40 |

| 4 | 100 | 114,30 | 157,20 | 11,11 | 0,80 | 76,20 | 152,40 |

| 5 | 125 | 141,30 | 185,70 | 11,11 | 1,58 | 76,20 | 203,20 |

| 6 | 150 | 168,27 | 215,90 | 12,70 | 1,58 | 88,90 | 203,20 |

| 8 | 200 | 219,07 | 269,80 | 12,70 | 1,58 | 101,60 | 203,20 |

| 10 | 250 | 273,05 | 323,80 | 12,70 | 1,58 | 127,00 | 254,00 |

| 12 | 300 | 323,85 | 381,00 | 12,70 | 1,58 | 152,40 | 254,00 |

| 14 | 350 | 355,60 | 412,70 | 12,70 | 1,58 | 152,40 | 304,80 |

| 16 | 400 | 406,40 | 469,90 | 12,70 | 1,58 | 152,40 | 304,80 |

| 18 | 450 | 457,20 | 533,40 | 12,70 | 1,58 | 152,40 | 304,80 |

| 20 | 500 | 508,00 | 584,20 | 12,70 | 1,58 | 152,40 | 304,80 |

| 22 | 550 | 558,80 | 641,30 | 12,70 | 1,58 | 152,40 | 304,80 |

| 24 | 600 | 609,60 | 692,10 | 12,70 | 1,58 | 152,40 | 304,80 |

| The lap thickness T shall not be less than nominal pipe wall thickness t | |||||||

Long Stub End Dimensional Tolerance

MSS SP-43 solely covers Stainless Steel Butt Weld Long Stub End Fittings created to be used with Schedule 5S and 10S Long Stub End appropriate to be used with Schedule 40S Pipe, as outlined in ASME B36.19. The scale and dimensional tolerances outlined in MSS SP-43 area unit considerably a similar as those in ASME B16.9 specifications from NPS 1/2 — NPS Twenty-four. Except with relation to the skin diameter at the bevel.

| Long Stub Ends | ||

| O.D. of Lap G | Fillet Radius of Lap – R | Overall Length. – F |

| +0 -1 | +0-1 | 2 |

| +0 -1 | +0-1 | 2 |

| +0 -1 | +0 -2 | 2 |

| +0-1 | +0 -2 | 2 |

| +0 -1 | +0 -2 | 2 |

| +0 -2 | +0 -2 | 2 |

| +0 -2 | +0-2 | 3 |

| +0 -2 | +0 -2 | 3 |

Long Stub End Weight Chart

| NPS

inihi |

STUB ENDS | |||

| Sch.

5S |

Sch.

10S |

Sch.

40S |

Sch.

80S |

|

| 1/2 | 0.06 | 0.08 | 0.12 | 0.13 |

| 3/4 | 0.07 | 0.09 | 0.15 | 0.17 |

| 1 | 0.09 | 0.15 | 0.20 | 0.25 |

| 1 1/4 | 0.13 | 0.20 | 0.30 | 0.35 |

| 1 1/2 | 0.16 | 0.25 | 0.38 | 0.46 |

| 2 | 0.25 | 0.40 | 0.55 | 0.75 |

| 2 1/2 | 0.35 | 0.50 | 0.80 | 1.00 |

| 3 | 0.50 | 0.60 | 1.10 | 1.50 |

| 4 | 0.70 | 1.00 | 1.80 | 2.50 |

| 5 | 1.00 | 1.25 | 2.50 | 3.50 |

| 6 | 1.60 | 1.95 | 3.70 | 5.50 |

| 8 | 2.50 | 3.10 | 5.90 | 10.0 |

| 10 | 4.00 | 4.90 | 10.5 | 14.0 |

| 12 | 6.60 | 7.10 | 15.0 | 20.0 |

| 14 | 6.40 | 7.80 | 15.5 | 20.5 |

| 16 | 7.90 | 9.00 | 18.0 | 24.0 |

| 18 | 9.30 | 10.5 | 21.0 | 28.0 |

| 20 | 12.0 | 13.5 | 23.5 | 31.0 |

| 24 | 16.5 | 19.0 | 28.5 | 38.0 |

| Approximate weights in kg, density 8 kg/dm3 | ||||

Long Stub End Angularity Tolerance

| ND | Max atu koki | Max atu i te rererangi |

| Q | P | |

| 1/2 a 4 | 1 | 2 |

| 5 a 8 | 2 | 4 |

| 10 a 12 | 3 | 5 |

| 14 a 16 | 3 | 7 |

| 18 a 24 | 4 | 10 |

| 26 a 30 | 5 | 10 |

| 32 a 42 | 5 | 13 |

| 44 a 48 | 5 | 20 |

ASME B16.9 Buttweld Long Stub End Available Types

| Buttweld Long Stub End | Butt Weld Long Stub Ends |

| ASME B16.9 Butt weld Long Stub End | Steel Long Stub Ends Fittings |

| Stainless Steel Long Stub End Suppliers | SS Buttweld Long Stub Ends Fitting |

| ANSI B16.9 Buttweld Long Stub End Dealer | ASME B16.28 Buttweld Long Stub Ends Exporter |

| Welded Butt weld Long Stub Ends Stockholder | Seamless Butt weld Long Stub End Distributors |

| Carbon Steel Long Stub End | High Quality Long Stub End Manufacturer |

| ASTM A403 Stainless Steel Long Stub Ends | Duplex Steel Buttweld Long Stub End |

| Super Duplex Steel Buttweld Long Stub End | Copper Nickel Long Stub End |

| High Nickel Alloy Long Stub Ends | Hastelloy Long Stub Ends Stockist |

| Titanium Buttweld Long Stub End | Inconel Butt weld Long Stub End |

Buttweld Long Stub End Application

- Stainless Steel Buttweld Long Stub End uses in Oil and Gas Pipeline

- Butt weld Long Stub Ends uses in Chemical Industry

- Alloy Steel Long Stub Ends uses in Plumbing

- Buttweld Long Stub Ends uses in Heating

- Buttweld Long Stub End Fittings uses in Water Supply Systems

- ANSI B16.9 Buttweld Long Stub Ends uses in Power Plant

- Buttweld Long Stub End Fitting uses in Paper & Pulp Industry

- Long Stub End uses in General Purpose Applications

- Buttweld Long Stub End uses in Fabrication Industry

- Long Stub End uses in Food Processing Industry

- Buttweld Long Stub Ends uses in Structural Pipe

Kowiri tira Pipa Kaiwhakarato Wenzhou Kaixin Haina

Kowiri tira Pipa Kaiwhakarato Wenzhou Kaixin Haina