Dengan penggunaan meluas paip keluli tahan karat, kualiti pemprosesan pengeluar paip keluli tahan karat menjadi semakin penting.

Pengeluar paip keluli tahan karat mesti memberi perhatian kepada setiap aspek untuk memastikan kualiti produk memenuhi keperluan pelanggan dan piawaian industri.

Mengikut piawaian industri dan keperluan pelanggan, keperluan kualiti pemprosesan pengeluar paip keluli tahan karat boleh dibahagikan kepada aspek berikut:

1. Kualiti bahan

The material quality of keluli tahan karat pipes directly affects the product quality.

Pengeluar paip keluli tahan karat Foshan mesti mengawal dengan ketat sumber dan kualiti bahan, dan secara munasabah memilih bahan dan aksesori yang sesuai.

2. Ketepatan dimensi dan geometri

Saiz dan ketepatan geometri paip keluli tahan karat adalah sangat penting.

Pengilang mesti menggunakan peralatan pemprosesan profesional dan teknologi untuk memastikan bahawa diameter, ketebalan dinding, panjang, dan kekuatan gelung paip memenuhi keperluan pelanggan dan piawaian industri.

Keperluan untuk ketepatan pemesinan harus kurang dari atau sama dengan 1%.

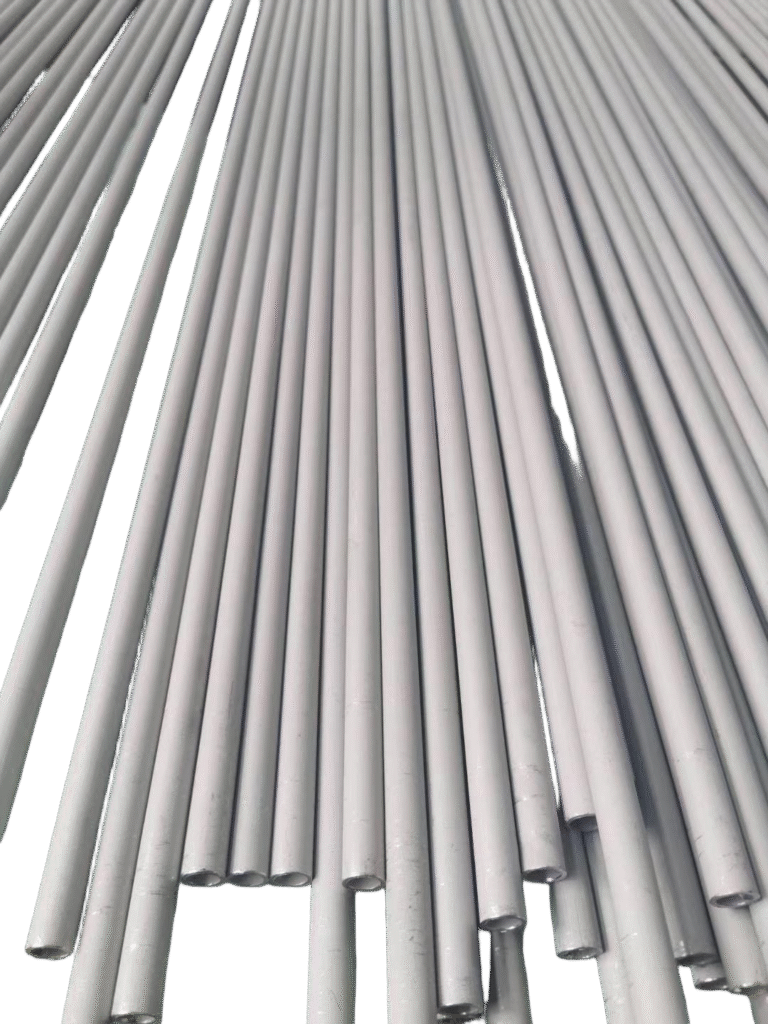

3. Kualiti permukaan

Kualiti permukaan paip keluli tahan karat adalah teras kesan visual dan rintangan kakisan.

Untuk mencapai kualiti permukaan berkualiti tinggi, Pengilang paip keluli tahan karat Foshan harus mengamalkan kaedah pemprosesan yang sesuai dan proses rawatan untuk menghapuskan kecacatan permukaan seperti salutan, gris, dan karat.

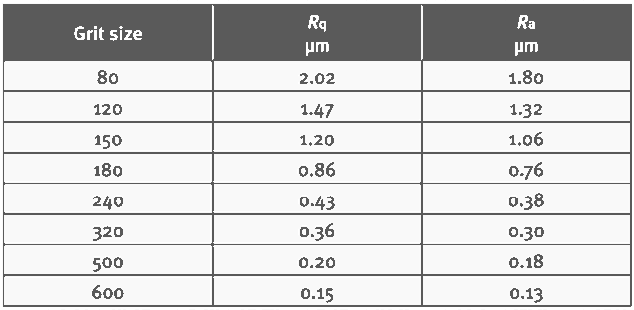

Kekasaran permukaan harus mematuhi piawaian kebangsaan, dan kemasan permukaan harus mencapai kualiti tertinggi mengikut keperluan pelanggan.

4. Komposisi dan sifat kimia

Komposisi kimia dan prestasi paip keluli tahan karat secara langsung mempengaruhi kestabilan mereka digunakan.

Pengilang paip keluli tahan karat Foshan mesti memantau dan menguji bahan mentah dengan ketat, Tentukan komposisi dan prestasi kimia, dan memastikan bahawa mereka memenuhi keperluan pelanggan dan piawaian industri.

5. Kualiti lain

Pengilang paip keluli tahan karat juga mesti memastikan kualiti produk mereka, seperti kekuatan, ketangguhan, Prestasi anti-karat, kebolehpercayaan, dll.

Ujian dan pengesahan yang sepadan harus dijalankan mengikut keperluan pelanggan dan piawaian industri.

Secara ringkasnya, paip keluli tahan karat Pengilang harus mempertimbangkan kualiti material, Ketepatan dimensi dan geometri, kualiti permukaan, Komposisi dan prestasi kimia, serta aspek kualiti lain semasa memproses paip keluli tahan karat, bagi memastikan kualiti produk menepati piawaian tertinggi. Hanya dengan cara ini kita boleh memenuhi keperluan pelanggan dan membentuk reputasi dan imej yang lebih tinggi untuk keseluruhan industri.

Wenzhou Kaixin Kaixin Metal Co., Ltd

Wenzhou Kaixin Kaixin Metal Co., Ltd