A stainless steel butt weld end cap is a type of welding fitting used to cover the end of a pipe or tube. It is made from high-quality stainless steel alloy and welded to the end of the pipe for a secure and leak-proof connection. Stainless steel butt weld end caps are commonly used in piping systems where the ends of pipes need to be sealed off to prevent fluids or gases from escaping. They come in various sizes and thicknesses, and can be customized to fit specific pipe requirements. They are widely used in different industries, including oil and gas, chemical, food and beverage, farmaceutyczny, and pulp and paper.

Buttweld Equal Cross Pipe Fitting Specifications

| Rozmiary | 1/2″ (15 Uwaga) to 48″ (1200Uwaga), Outside diameter : 1/2″ à 24″ (21,34 – 609,5 mm) |

| Standardy | Ansi - b 16.9, ASTM A403 - ASME SA403 - „Standardowa specyfikacja kutego austenitycznego złączek rur nierdzewnych”, API 590-605, ASME B16.9-„Fabrycznie wykonane z kutego tyłki”, ASME B16.25 - „Endwelding kończy się”, ASME B16.28 - „Kute stalowe Buttwelding krótkie łokcie i zwroty”, MSS SP-43-„Wykreślające i sfabrykowane złączki do spopie, Zastosowania odporne na korozję ” |

| Wymiary | ASME/ANSI B16.9, MSS-SP-43 Typ A., MSS-SP-43 Typ B., Tylko B2312, JIS B2313, ASME B16.28 |

| Grubość | Harmonogram 5s, 10S, 20S, S10, S20, S30, Std, 40S, S40, S60, Xs, 80S, S80, S100, S120, S140, S160, XXS i itp. |

| End Caping Radius | R=10D

|

| Z | End Caps, Pipe Caps, Pipe End Caps, Steel Pipe End Caps. |

| Grades&Przybory | ASTM A403 WP316/316L, ASTM A403 WP304/304L, ASTM A182 F316L, 304L, Z 1.4301, DIN1.4306, Z 1.4401, Z 1.4404, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L,ASTM A234, ASME SA234 WPB , WPBW, Wphy 42, Wphy 46, Wphy 52, Wph 60, Wphy 65 & Wphy 70. ASME SA234 WP1 / WP5 / WP9 / WP11 / WP22 / WP91, ASTM A815, ASME SA815 UNS No S31803, S32205,S32750, S32950, ASTM B336, ASME SB336, Nikiel 200 (Nas nie. NO2200), Nikiel 201 (Nas nie. N02201), Monel 400 (Nas nie. N04400), Monel 500 (Nas nie. N05500), Niewygod 800 (Nas nie. N08800), Niewygod 825 (Nas nie. N08825), Niewygod 600 (Nas nie. N06600), Niewygod 625 (Nas nie. N06625), Niewygod 601 (Nas nie. N06601), Hastelloy c 276 (Nas nie. N10276), Stop 20 (Nas nie. N08020), Tytan (Klasa I. & Ii), Cupro-Nickel 70/30, CUNI10FE1MN, CUNI30MN1FE. |

| Typ | Spawana (BW) / Bezszwowy / Spawany / Erw / Sfabrykowany |

| Powłoka / Obróbka powierzchniowa | Farba antykorozyjna, Czarna farba olejna, Żółty przezroczysty, Ocynkowane, Cold and Hot Dip Galvanized |

Buttweld End Cap Manufacturing Standards

| ASME Standard | ASME/ANSI B16.9, ASME/ANSI B16.28, MSS-SP-43 |

| DIN Standard | DIN28011, DIN2617, DIN2616, DIN2615, DIN2605 |

| EN Standard | EN10253-2, EN10253-1 |

| ASME B16.25 | Buttwelding Ends |

| ASME B16.9 | Factory-Made Wrought Fittings Buttwelding |

| ASME B16.28 | Wrought Steel End Cap and Buttwelding Returns |

| ASTM A403 – ASME SA403 | Standard Specification for Wrought Austenitic SS Piping Fitting |

| MSS SP-43 | Wrought & Fabricated Butt-Welding Fitting for Low Pressure, Corrosion Resistant Applications |

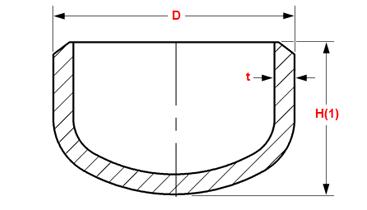

DIMENSIONS OF END CAPS

Stainless Steel Buttweld End Cap Dimention Drawing

| NPS | O.D. D |

LENGTH H |

LENGTH H1 |

| 1/2 | 21.3 | 25 | 25 |

| 3/4 | 26.7 | 25 | 25 |

| 1 | 33.4 | 38 | 38 |

| 1.1/4 | 42.2 | 38 | 38 |

| 1.1/2 | 48.3 | 38 | 38 |

| 2 | 60.3 | 38 | 44 |

| 2.1/2 | 73 | 38 | 51 |

| 3 | 88.9 | 51 | 64 |

| 3.1/2 | 101.6 | 64 | 76 |

| 4 | 114.3 | 64 | 76 |

| 5 | 141.3 | 76 | 89 |

| 6 | 168.3 | 89 | 102 |

| 8 | 219.1 | 102 | 127 |

| 10 | 273 | 127 | 152 |

| 12 | 323.8 | 152 | 178 |

| 14 | 355.6 | 165 | 191 |

| 16 | 406.4 | 178 | 203 |

| 18 | 457 | 203 | 229 |

| 20 | 508 | 229 | 254 |

| 22 | 559 | 254 | 254 |

| 24 | 610 | 267 | 305 |

| 26 | 660 | 267 | … |

| 28 | 711 | 267 | … |

| 30 | 762 | 267 | … |

| 32 | 813 | 267 | … |

| 34 | 864 | 237 | … |

| 36 | 914 | 267 | … |

| 38 | 965 | 305 | … |

| 40 | 1016 | 305 | … |

| 42 | 1067 | 305 | … |

| 44 | 1118 | 343 | … |

| 46 | 1168 | 343 | … |

| 48 | 1219 | 343 | … |

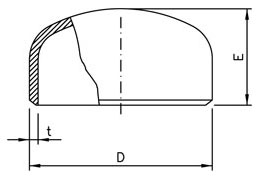

Stainless Steel Buttweld End Cap Dimention Drawing2

| CAPS – ANSI B 16.9 dimension | |||

| Cale | mm | Height | |

| D | mi | ||

| 1/2 | 15 | 21,34 | 25,40 |

| 3/4 | 20 | 26,67 | 31,75 |

| 25 | 33,40 | 38,10 | |

| 1 1/4 | 32 | 42,16 | 38,10 |

| 1 1/2 | 40 | 48,26 | 38,10 |

| 2 | 50 | 60,32 | 38,10 |

| 2 1/2 | 65 | 73,02 | 38,10 |

| 3 | 80 | 88,90 | 50,80 |

| 3 1/2 | 90 | 101,60 | 63,50 |

| 4 | 100 | 114,30 | 63,50 |

| 5 | 125 | 141,30 | 76,20 |

| 6 | 150 | 168,27 | 88,90 |

| 8 | 200 | 219,07 | 101,60 |

| 10 | 250 | 273,05 | 127,00 |

| 12 | 300 | 323,85 | 152,40 |

| 14 | 350 | 355,60 | 165,10 |

| 16 | 400 | 406,40 | 177,80 |

| 18 | 450 | 457,20 | 203,20 |

| 20 | 500 | 508,00 | 228,60 |

| 22 | 550 | 558,80 | 254,00 |

| 24 | 600 | 609,60 | 266,70 |

| 28 | 700 | 711,20 | 266,70 |

| Dimension in mm | |||

DIMENSIONAL TOLERANCES – CAPS

| DIMENSIONAL TOLERANCES – CAPS | ||||

| For all fittings | Caps | |||

| Nominalny rozmiar rury (NPS) | Outside Ø at Bevel | Inside Ø at End | Grubość ściany T / T1 |

Overall Length E |

| 1/2 A 2 1/2 | 1 | 0,8 | Nie | 4 |

| 3 A 3 1/2 | 1 | 1,6 | less | 4 |

| 4 | +2 -1 | 1,6 | than | 4 |

| 5 A 6 | +3 -1 | 1,6 | 87,50% | 7 |

| 8 | 2 | 1,6 | nominałów | 7 |

| 10 | +4 -3 | 3,2 | tickness | 7 |

| 12 A 18 | +4-3 | 3,2 | 7 | |

| 20 A 24 | +6-5 | 4,8 | 7 | |

| 26 A 30 | +7 -5 | 4,8 | 10 | |

| 32 A 48 | +7 -5 | 4,8 | 10 | |

Weight of SS Buttweld End Caps

| NPS | Std | Xs | Sch 160 | XXS |

| 1 | 0.09 | 0.14 | 0.18 | 0.23 |

| 1.1/4 | 0.14 | 0.18 | 0.23 | 0.34 |

| 1.1/2 | 0.18 | 0.23 | 0.27 | 0.41 |

| 2 | 0.27 | 0.34 | 0.57 | 0.68 |

| 2.1/2 | 0.41 | 0.45 | 0.79 | 1.13 |

| 3 | 0.68 | 0.79 | 1.32 | 1.81 |

| 3.1/2 | 0.91 | 1.13 | – | 2.72 |

| 4 | 1.13 | 1.36 | 2.68 | 3.4 |

| 5 | 2.04 | 2.49 | 4.54 | 5.44 |

| 6 | 2.95 | 4.08 | 6.8 | 8.16 |

| 8 | 5.44 | 7.26 | 14.06 | 13.61 |

| 10 | 9.07 | 11.34 | 25.85 | – |

| 12 | 13.61 | 16.33 | 43.09 | – |

| 14 | 16.33 | 20.41 | – | – |

| 16 | 18.14 | 24.49 | – | – |

| 18 | 24.49 | 32.66 | – | – |

| 20 | 34.02 | 39.01 | – | – |

| 22 | 42.64 | 56.7 | – | – |

| 24 | 43.54 | 58.97 | – | – |

| 26 | 53.98 | 72.12 | – | – |

| 30 | 78.02 | 103.87 | – | – |

| NPS | Std | Xs | Sch 160 | XXS |

ASME B16.9 SS End Cap Angularity Tolerance

| Nd | Maksymalnie nie pod kątem | Maksymalny samolot |

| Q | P | |

| 1/2 A 4 | 1 | 2 |

| 5 A 8 | 2 | 4 |

| 10 A 12 | 3 | 5 |

| 14 A 16 | 3 | 7 |

| 18 A 24 | 4 | 10 |

| 26 A 30 | 5 | 10 |

| 32 A 42 | 5 | 13 |

| 44 A 48 | 5 | 20 |

BUTTWELD END CAP – MATERIALS & Oceny

| Stainless Steel Buttweld End Cap | ASTM A403 WP316/316L, ASTM A403 To / A 774 WP-S, WP-W, WP-WX 304/304L, ASTM A182 F316L, 304L, Z 1.4301, DIN1.4306, Z 1.4401, Z 1.4404 |

| Dupleks & Super Duplex Steel Buttweld End Cap | ASTM A 815, Asme to 815 No S31803, S32205. US S32750, S32950. Materiał nr. 1.4462 |

| Carbon Steel Buttweld End Cap | ASTM A234, ASME SA234 WPB , WPBW, Wphy 42, Wphy 46, Wphy 52, Wph 60, Wphy 65 & Wphy 70. |

| Low Temperature Carbon Steel Buttweld End Cap | ASTM A420 WPL3, A420 WPL6 |

| Alloy Steel Buttweld End Cap | ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

| Nickel Alloy Buttweld End Cap | ASTM B336, ASME SB336, Nikiel 200 (Nas nie. NO2200), Nikiel 201 (Nas nie. N02201), Monel 400 (Nas nie. N04400), Monel 500 (Nas nie. N05500), Niewygod 800 (Nas nie. N08800), Niewygod 825 (Nas nie. N08825), Niewygod 600 (Nas nie. N06600), Niewygod 625 (Nas nie. N06625), Niewygod 601 (Nas nie. N06601), Hastelloy c 276 (Nas nie. N10276), Stop 20 (Nas nie. N08020), Tytan (Klasa I. & Ii), Cupro-Nickel 70/30, CUNI10FE1MN, CUNI30MN1FE. |

Different End Cap Shapes

ASME B16.9 Pipe End Cap Are Available In Various Shapes

- End Cap Square

- End Cap Round

- End Cap Rectangular

- “U” Shape End Cap

- “I” Shape End Cap

- Hex End Cap

- Hemispherical End Cap

- Oval End Cap

Advantages of Buttweld End Cap

- Offer permanent leakproof

- Adds strength and power to the pipng structure

- Reduce pressure losses

- Deliver a framework that uses atleast space

Types of End Cap

| Butt weld End Caps | Seamless Buttweld Caps |

| ASME B16.28 Buttweld Pipe End Caps | MSS-SP-43 Buttweld Pipe Caps |

| JIS B2313 Buttweld Pipe End Cap | JIS B2312 Buttweld Pipe Cap |

| End Cap Pipe Fittings | Welded Butt weld End Cap |

| Forged End Cap Pipe Fittings | Threaded End Cap |

| ANSI B16.9 End Cap | Fabricated Pipe End Cap |

Buttweld End Cap Application

ASME B16.9 End Cap are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a broad range of Buttweld Cap through a worldwide network of stock-keeping branches. These End Pipe Cap is use in various industries like :

- Stainless Steel Buttweld End Cap uses in Oil and Gas Pipeline

- Butt weld End Caps uses in Chemical Industry

- Alloy Steel End Caps uses in Plumbing

- Buttweld Eccentric Pipe Cap uses in Heating

- Buttweld End Cap Fittings uses in Water Supply Systems

- ANSI B16.9 Buttweld End Caps uses in Power Plant

- Buttweld End Cap Fitting uses in Paper & Pulp Industry

- End Cap uses in General Purpose Applications

- Buttweld End Cap uses in Fabrication Industry

- End Cap uses in Food Processing Industry

- Buttweld End Caps uses in Structural Pipe

Dostawca rur ze stali nierdzewnej Wenzhou Kaixin Chiny

Dostawca rur ze stali nierdzewnej Wenzhou Kaixin Chiny