A butt weld 45 degree long radius elbow is a type of pipe fitting that is used to change the direction of the flow in a piping system by 45 degrees. It is designed with a long radius, which means that the curvature of the elbow is relatively gentle, allowing for a smoother flow of fluid through the system. Butt weld 45 degree long radius elbows are made by welding two pipes or tubes together at a 45 degree angle, with the weld seam being flush with the surface of the elbow. They are commonly used in industries such as oil and gas, petrochemicals, and power generation to connect pipes and redirect the flow of fluids around obstacles or through corners.

Butt weld Fitting 45° Long Radius Elbow Specification

| Tiêu chuẩn | ANSI/ASME :ASTM A403 / ASME SA403, ANSI B16.9, ASME B16.25, ASME B16.28, MSS SP-43.

TỪ : DIN2605, DIN2615, DIN2616, Từ 2617, DIN28011 TRONG : EN10253-1, EN10253-2 |

| Lịch trình | Lịch trình 5s, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, Xxs và vv. |

| Kích thước | Seamless 45° Long Radius Elbow Size: 1/2″~24″

Erw / Hàn / Fabricated 45° Long Radius Elbow Size: 1/2″ (15 NB) to 48″ (1200NB) |

| Điểm | 304/L/H/LN, 316/L/H/LN/Ti, 321/H, 317/L/LN, 347/H, 310S/H, N08904(904L), S31803,S32205, S32750, S32760, N02200, N02201, N04400, N06600, N06690, N06625, N06985(G3), N08028, N08800, N08810, N08811, N08825Surface |

| Kiểu | Mối hàn mông (BW) / Hàn / Erw / Bịa đặt |

| Kích thước | ANSI B16.9, ANSI B16.28, MSS-SP-43 Loại A, MSS-SP-43 Loại B., |

Butt weld Fitting 45° Long Radius Elbow MATERIAL & GRADES

| Stainless Steel Buttweld 45 Khuỷu tay bán kính dài | ASTM A403 WP316/316L, ASTM A403 SA / A 774 WP-S, WP-W, WP-WX 304/304L, ASTM A182 F316L, 304L, TỪ 1.4301, DIN1.4306, TỪ 1.4401, TỪ 1.4404 |

| Song công & Super Duplex Steel Buttweld 45 Khuỷu tay bán kính dài | ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Hoa Kỳ S32750, S32950. Tài liệu không. 1.4462 |

| Carbon Steel Buttweld 45 Khuỷu tay bán kính dài | ASTM A234, ASME SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

| Low Temperature Carbon Steel 45 Khuỷu tay bán kính dài | ASTM A420 WPL3, A420 WPL6 |

| Alloy Steel Buttweld 45 Khuỷu tay bán kính dài | ASTM / Asme's/That 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

| Nickel Alloy Buttweld 45 Khuỷu tay bán kính dài | ASTM B336, ASME SB336, Niken 200 (Chúng tôi không. NO2200), Niken 201 (Chúng tôi không. N02201), Monel 400 (Chúng tôi không. N04400), Monel 500 (Chúng tôi không. N05500), Bất tiện 800 (Chúng tôi không. N08800), Bất tiện 825 (Chúng tôi không. N08825), Bất tiện 600 (Chúng tôi không. N06600), Bất tiện 625 (Chúng tôi không. N06625), Bất tiện 601 (Chúng tôi không. N06601), Hastelloy c 276 (Chúng tôi không. N10276), Hợp kim 20 (Chúng tôi không. N08020), Titan (Lớp i & Ii), Cupro-Nickel 70/30, CUNI10FE1MN, CUNI30MN1FE. |

Applications of 45 DEGREE LONG RADIUS ELBOW

- Stainless Steel 45° Long Radius Elbow uses in Oil and Gas Pipeline

- 45° Buttweld LR Elbow uses in Chemical Industry

- Alloy Steel 45° Long Radius Elbow uses in Plumbing

- 45° Long Radius Elbow Pipe Fittings uses in Food Processing Industry

- Buttweld 45° LR Elbow uses in Structural Pipe

- ANSI B16.9 Buttweld 45° Long Radius Elbow uses in Power Plant

- 45° Long Radius Pipe Elbow uses in Paper & Ngành công nghiệp bột giấy

- 45 Deg Long Radius Bend uses in Heating

- 45 Degree Long Radius Reducing Elbow uses in Water Supply Systems

- ASME B16.9 Long Radius 45 Deg Elbow uses in General Purpose Applications

- 45° LR Elbow uses in Fabrication Industry

45 Deg Long Radius Elbow Kích thước

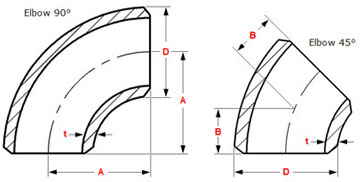

mông 45 Degree Long Radius Elbow Dimension Drawing

| NPS | O.D.

D |

90 degrees

Long Radius Center-to-End A |

45 degrees

Long Radius Center-to-End B |

90 degrees

3D Center-to-End A |

45 degrees

3D Center-to-End B |

| 1/2 | 21.3 | 38 | 16 | – | – |

| 3/4 | 26.7 | 38 | 19 | 57 | 24 |

| 1 | 33.4 | 38 | 22 | 76 | 31 |

| 1 ¼ | 42.2 | 48 | 25 | 95 | 39 |

| 1 ½ | 48.3 | 57 | 29 | 114 | 47 |

| 2 | 60.3 | 76 | 35 | 152 | 63 |

| 2 ½ | 73 | 95 | 44 | 190 | 79 |

| 3 | 88.9 | 114 | 51 | 229 | 95 |

| 3 ½ | 101.6 | 133 | 57 | 267 | 111 |

| 4 | 114.3 | 152 | 64 | 305 | 127 |

| 5 | 141.3 | 190 | 79 | 381 | 157 |

| 6 | 168.3 | 229 | 95 | 457 | 189 |

| 8 | 219.1 | 305 | 127 | 610 | 252 |

| 10 | 273 | 381 | 159 | 762 | 316 |

| 12 | 323.8 | 457 | 190 | 914 | 378 |

| 14 | 355.6 | 533 | 222 | 1067 | 441 |

| 16 | 406.4 | 610 | 254 | 1219 | 505 |

| 18 | 457 | 686 | 286 | 1372 | 568 |

| 20 | 508 | 762 | 318 | 1524 | 632 |

| 22 | 559 | 838 | 343 | 1676 | 694 |

| 24 | 610 | 914 | 381 | 1829 | 757 |

| 26 | 660 | 991 | 406 | 1981 | 821 |

| 28 | 711 | 1067 | 438 | 2134 | 883 |

| 30 | 762 | 1143 | 470 | 2286 | 964 |

| 32 | 813 | 1219 | 502 | 2438 | 1010 |

| 34 | 864 | 1295 | 533 | 2591 | 1073 |

| 36 | 914 | 1372 | 565 | 2743 | 1135 |

| 38 | 965 | 1448 | 600 | 2896 | 1200 |

| 40 | 1016 | 1524 | 632 | 3048 | 1264 |

| 42 | 1067 | 1600 | 660 | 3200 | 1326 |

| 44 | 1118 | 1676 | 695 | 3353 | 1389 |

| 46 | 1168 | 1753 | 727 | 3505 | 1453 |

| 48 | 1219 | 1829 | 759 | 3658 | 1516 |

DIMENSIONAL TOLERANCES OF 45 DEGREE LONG RADIUS ELBOW – ASME B16.9

| DIMENSIONAL TOLERANCES – ELBOWS | |||||||

| For all fittings | Elbows 90/45 deg | 180° Returns | |||||

| Kích thước ống danh nghĩa (NPS) | Outside Ø

ở góc độ |

Inside Ø

at End |

Độ dày tường

t / t1 |

Center to End Dim. A-B-C-M | Center to Center Dim.

O |

Back to Face Dim.

K |

Align- ment of Ends

U |

| 1/2 Một 2 1/2 | 1 | 0,8 | Not | 2 | 7 | 7 | 1 |

| 3 Một 3 1/2 | 1 | 1,6 | less | 2 | 7 | 7 | 1 |

| 4 | +2 -1 | 1,6 | than | 2 | 7 | 7 | 1 |

| 5 Một 6 | +3 -1 | 1,6 | 87,50% | 2 | 7 | 7 | 1 |

| 8 | 2 | 1,6 | of nominal | 2 | 7 | 7 | 1 |

| 10 | +4 -3 | 3,2 | tickness | 2 | 7 | 7 | 2 |

| 12 Một 18 | +4 -3 | 3,2 | 3 | 10 | 7 | 2 | |

| 20 Một 24 | +6 -5 | 4,8 | 3 | 10 | 7 | 2 | |

| 26 Một 30 | +7 -5 | 4,8 | 3 | ….. | ….. | ….. | |

| 32 Một 48 | +7 -5 | 4,8 | 5 | ….. | ….. | ….. | |

ANGULARITY TOLERANCES OF 45 DEGREE LONG RADIUS ELBOW

| Angularity Tolerances | ||

| ND | Tối đa góc ngoài | Tối đa tắt máy bay |

| Q. | P | |

| 1/2 Một 4 | 1 | 2 |

| 5 Một 8 | 2 | 4 |

| 10 Một 12 | 3 | 5 |

| 14 Một 16 | 3 | 7 |

| 18 Một 24 | 4 | 10 |

| 26 Một 30 | 5 | 10 |

| 32 Một 42 | 5 | 13 |

| 44 Một 48 | 5 | 20 |

AVAILABLE TYPES OF 45 DEGREE LONG RADIUS ELBOW

| Buttweld 45° Long Radius Elbow | Duplex Steel Buttweld 45° Long Radius Elbow |

| ASME B16.9 Butt weld 45° Long Radius Elbow | High Nickel Alloy 45° Long Radius Elbow |

| Stainless Steel 45° Long Radius Elbow | SS 45° Long Radius Elbow |

| High Quality 45° Long Radius Elbow | Seamless Butt weld 45° Long Radius Elbow |

| Welded Butt weld 45° Long Radius Elbowr | ASME B16.28 Buttweld 45° Long Radius Elbow |

| Carbon Steel 45° Long Radius Elbow | ANSI B16.9 Buttweld 45° Long Radius Elbow |

| Titanium Buttweld 45° Long Radius Elbow | Inconel Butt weld 45° Long Radius Elbow |

| ASTM A403 Stainless Steel 45° Long Radius Elbow | Butt Weld B16.9 45° Long Radius Elbow |

| Super Duplex Steel Buttweld 45° Long Radius Elbow | Copper Nickel 45° Long Radius Elbow |

| Steel 45° Long Radius Elbow | Hastelloy 45° Long Radius Elbow |

WEIGHT OF 45 Deg Long Radius Elbow

Buttweld Elbow Weight in LBS and KG

| Type-> | SCHEDULE STD | SCHEDULE XS |

| NPS | LBS | KG | LBS | KG |

| 1/2 | 0.09 | 0.04 | 0.19 | 0.09 |

| 3/4 | 0.09 | 0.04 | 0.19 | 0.09 |

| 1 | 0.25 | 0.11 | 0.31 | 0.14 |

| 1 ¼ | 0.38 | 0.17 | 0.5 | 0.23 |

| 1 ½ | 0.4 | 0.18 | 0.69 | 0.31 |

| 2 | 0.81 | 0.37 | 1.19 | 0.54 |

| 2 ½ | 1.75 | 0.79 | 2.13 | 0.97 |

| 3 | 2.63 | 1.19 | 3.5 | 1.59 |

| 3 ½ | 3.5 | 1.59 | 4.5 | 2.04 |

| 4 | 4.5 | 2.04 | 6.1 | 2.77 |

| 5 | 7.5 | 3.4 | 10.7 | 4.85 |

| 6 | 12 | 5.44 | 17.5 | 7.94 |

| 8 | 23 | 10.43 | 35 | 15.88 |

| 10 | 43 | 19.5 | 53 | 24.04 |

| 12 | 62 | 28.12 | 84 | 38.1 |

| 14 | 80 | 36.29 | 100 | 45.36 |

| 16 | 100 | 45.36 | 135 | 61.23 |

| 18 | 126 | 57.15 | 167 | 75.75 |

| 20 | 160 | 72.57 | 206 | 93.44 |

| 22 | 197 | 89.36 | 260 | 117.93 |

| 24 | 238 | 107.95 | 300 | 136.08 |

| 26 | 275 | 124.74 | 365 | 165.56 |

| 30 | 367 | 166.47 | 488 | 221.35 |

| 36 | 531 | 240.86 | 706 | 320.24 |

45 Degree Elbow Cutting Formula

- R1 = elbow radius marking 1

- R2 = elbow radius marking 2

- R3 = elbow radius marking 3

EC = Elbow Center

OD = Outside Daimeter

R2 = Both Side Radius Marking

45 Degree Elbow Take Off Formula

(R1) – tan x 1 x (EC – 1/2 CỦA) x Deg = answar

(R2) – tan x 1 x EC … x Deg = answar

(R3) – tan x 1 (EC + 1/2 CỦA) x deg = answar

Nhà cung cấp ống thép không gỉ Ôn Châu Kaixin Trung Quốc

Nhà cung cấp ống thép không gỉ Ôn Châu Kaixin Trung Quốc