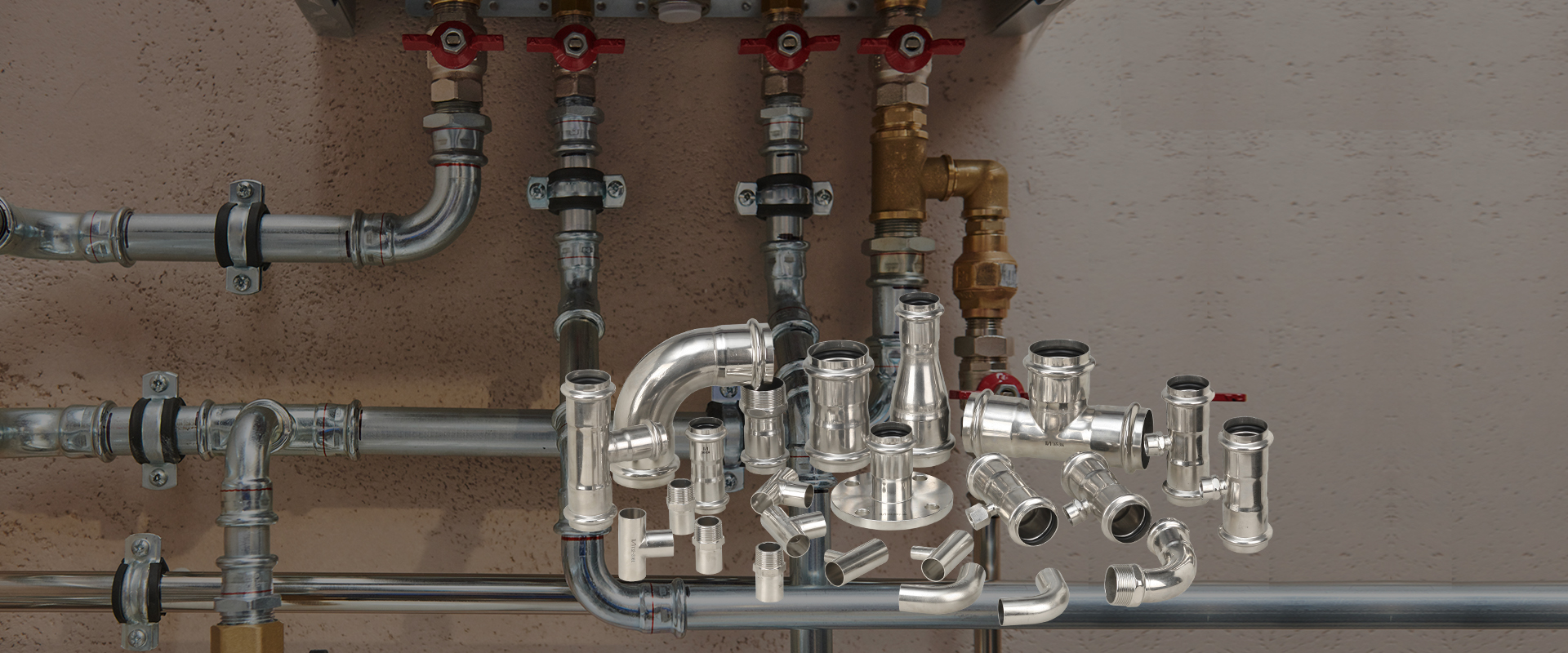

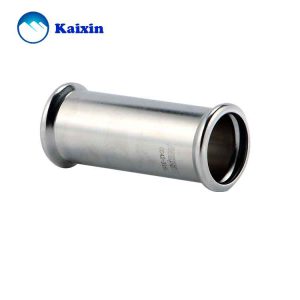

Made from high-quality 304 stainless steel, this press fitting is durable, corrosion-resistant, and able to withstand high-pressure environments. The V profile design ensures a secure and leak-free connection, while the press-fit installation makes for quick and easy installation without the need for welding or soldering.

Some of the features of the Stainless Steel 90 Degree Elbow Pipe Press Fitting include:

– Made from high-quality 304 stainless steel

– V profile design for a secure and leak-free connection

– Press-fit installation for easy and quick installation

– Suitable for use in plumbing, HVAC, and industrial applications

– Corrosion-resistant and able to withstand high-pressure environments

קוילעלדיק, the V Profile 304 Stainless Steel 90 Degree Elbow Pipe Press Fitting is a reliable and efficient option for connecting pipes at a 90-degree angle. Its high-quality construction and easy installation make it a popular choice for a wide range of applications.

Specification

| Product Name | Stainless Steel 304 M V Profile 90 Degree Elbow Pipe Press Fitting |

| Material | SS304,SS316L |

| Standard | According to customers |

| Size | 185mm X 2.5″ |

| MOQ | 5 piece |

| Delivery | 7 days |

| Connection | Press fitting |

| Used | Beverage,beer,water treatment,comestic,pharmacy,אאז"ו ו |

Drawing and weight of V Profile Stainless Steel 90 Degree Elbow Pipe Press Fitting

| d (mm) |

L (mm) |

(mm ) | Weight (g) |

| 15 | 46±3 | 24±3 | 52 |

| 18 | 49±3 | 27±3 | 62 |

| 22 | 56±3 | 32±3 | 93 |

| 28 | 64±4 | 39±4 | 1,284 |

| 35 | 72±4 | 45±4 | 1,756 |

| 42 | 93±4 | 58±4 | 265 |

| 54 | 112±4 | 74±4 | 3,998 |

Stainless steel pipes for pipeline systems. Technical characteristics.

| Material | External diameterx thickness dxs [mm] |

DN | Volume of water contained [dm³/m] |

Empty weight [kg/m] |

| Austenitic stainless steel X2 CrNiMo 17-12-2 n.1.4404 A/SI 316L) according to UNIEN 10088-2,UNIEN 10217-7 and UNIEN 10312 |

15,0×1,0 | 12 | 133 | 351 |

| 18,0 x1,0 | 15 | 0.20 | 426 | |

| 22,0×1,2 | 20 | 302 | 625 | |

| 28,0×1,2 | 25 | 514 | 805 | |

| 35,0×1,5 | 32 | 804 | 1,258 | |

| 42,0×1,5 | 40 | 1,195 | 1,521 | |

| 54,0×1,5 | 50 | 2,043 | 1,972 | |

| 76,1×2,0 | 65 | 4,083 | 3,711 | |

| 88,9 x2,0 | 80 | 5,661 | 4,352 | |

| 108,0×2,0 | 100 | 8,495 | 5,308 | |

| -Tensile strength Rm:490-690 N/mm² | ||||

| -Yieldresistance Rp0,2:≥ 190 N/mm² | ||||

| – LongitudinalLengthening A:≥ 40% | ||||

| -Bendingradiusr:≥3,5d (uptodiameter28) | ||||

ומבאַפלעקט שטאָל רער סאַפּלייער ווענזשאָו קאַיקסין טשיינאַ

ומבאַפלעקט שטאָל רער סאַפּלייער ווענזשאָו קאַיקסין טשיינאַ