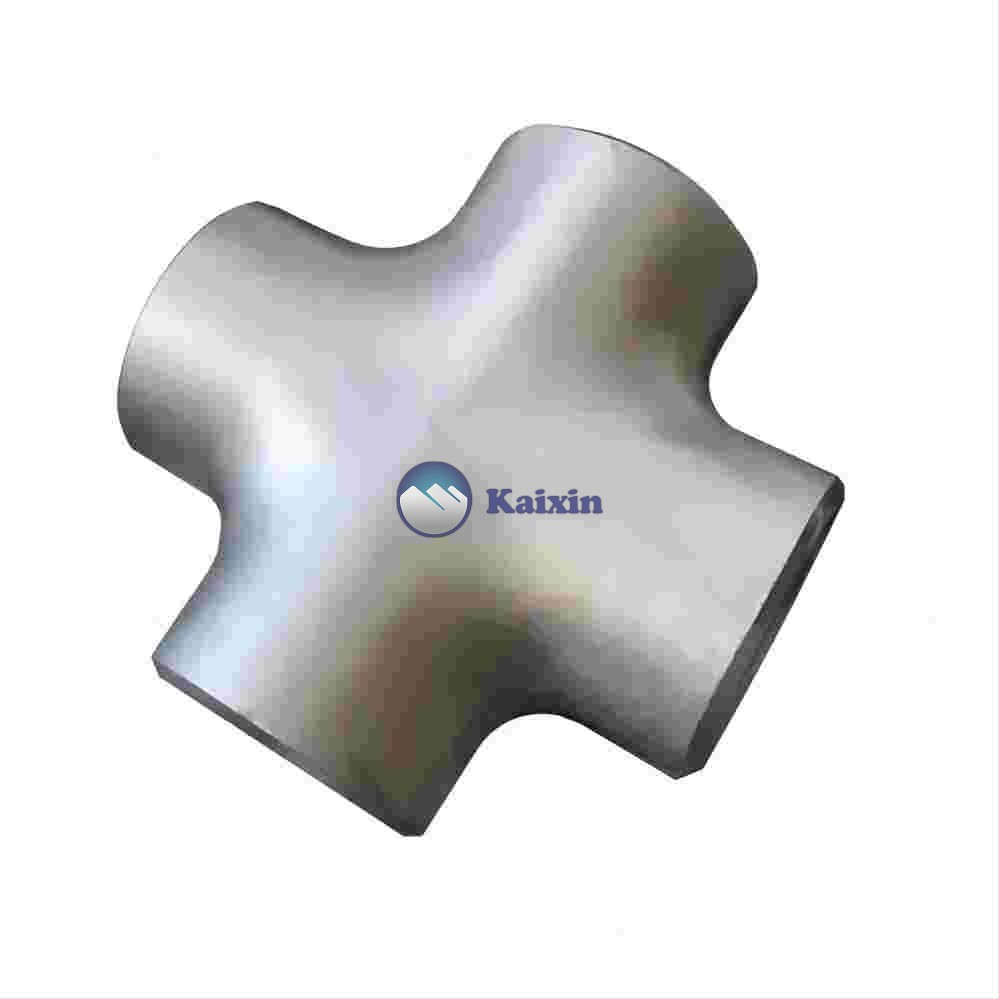

A Buttweld Pipe Equal Cross is a kind of Pipe Fitting that be utilized in the place where four pipes meet together. The Butt Weld cross may have one inlet and three outlets, or their inlets and one outlet. Buttweld Equal Cross Fittings are utilized in several industries for providing leak-free and torque free sealing in any piping or tubing connection. Offered in various grades Buttweld Equal Cross Fittings are reckoned for their close tolerances and excellent finishes.

The Equal Cross is one reason the pipe cross, similar to an Equal Tee, the butt weld Equal Cross means all the four ends of the cross are within the same diameter. This equal cross has four ends of the cross are in equal diameter. the stainless steel Equal Cross is obtainable in several specifications that adjust in standards, 室壁厚度, types, forms.

对焊等径四通管件规格

| 尺寸 | 无缝管相等的杂交 ( 1/2”~24”), 英亩 / 焊接式 / 制造的管相等 (1/2”~48”) |

| 标准 | ANSI – B 16.9, ASTM A403 – ASME SA403 – “锻造奥氏体不锈钢管道配件的标准规范”, 应用程序编程接口 590-605, ASME B16.9 – “工厂制造的锻造对焊配件”, ASME B16.25 – “对焊端部”, ASME B16.28 –“锻钢对焊短半径弯头和回程”, MSS SP-43 –“低压锻造和装配式对焊配件”, 耐腐蚀应用” |

| 方面 | ASME/ANSI B16.9, MSS-SP-43 A型, MSS-SP-43 B型, JIS B2312, JIS B2313, ASME B16.28 |

| 厚度 | 附表5S, 10S, 20S, S10, S20, S30, 性病, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS等. |

| 弯曲半径 | R=1D – 10D, 15D, 20D

|

| 从 | 管道十字架, Equal Cross, Fitting Cross, Butt weld Cross |

| 成绩&材料 | ASTM A403 WP316/316L, ASTM A403 WP304/304L, ASTM A182 F316L, 304L, 从 1.4301, DIN1.4306, 从 1.4401, 从 1.4404, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L,ASTM A234, ASME SA234 WPB , 工作带宽, 世界物理研究所 42, 世界物理研究所 46, 世界物理研究所 52, WPH 60, 世界物理研究所 65 & 世界物理研究所 70. ASME SA234 WP1 / WP5 / WP9 / WP11 / WP22 / WP91, ASTM A815, ASME SA815 UNS 编号 S31803, S32205,S32750, S32950, ASTM B336, 美国机械工程师协会SB336, 镍 200 (联合国编号. 2200号), 镍 201 (联合国编号. N02201), 蒙乃尔合金 400 (联合国编号. N04400), 蒙乃尔合金 500 (联合国编号. N05500), 铬镍铁合金 800 (联合国编号. N08800), 铬镍铁合金 825 (联合国编号. N08825), 铬镍铁合金 600 (联合国编号. N06600), 铬镍铁合金 625 (联合国编号. N06625), 铬镍铁合金 601 (联合国编号. N06601), 哈氏合金C 276 (联合国编号. N10276), 合金 20 (联合国编号. N08020), 钛 (一级 & 二), 铜镍合金 70/30, 铜镍10铁1锰, 铜镍30锰1铁.

|

| 类型 | 对焊 (体重) / 无缝的 / 焊接式 / 英亩 / 捏造的 |

| 涂层 / 表面处理 | 防锈漆, 油黑漆, 黄色透明, 镀锌, 冷热镀锌 |

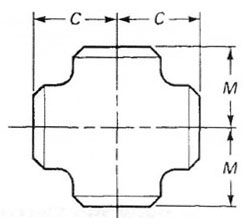

DIMENSIONS OF BUTTWELD EQUAL CROSS – ANSI 16.9

Stainless Steel Equal Cross Fitting Drawing

| 公称管道尺寸 (核动力源) | DN | 斜角处外径 | 中心- to-End | |

| Run.C | 出路. 中号[Notes(1) 和 (2)] | |||

| 1/2 | 15 | 21.3 | 25 | 25 |

| 3/4 | 20 | 26.7 | 29 | 29 |

| 1 | 25 | 33.4 | 38 | 38 |

| 1-1/4 | 32 | 42.2 | 48 | 48 |

| 1-1/2 | 40 | 48.3 | 57 | 57 |

| 2 | 50 | 60.3 | 64 | 64 |

| 2-1/2 | 65 | 73.0 | 76 | 76 |

| 3 | 80 | 88.9 | 86 | 86 |

| 3-1/2 | 90 | 101.6 | 95 | 95 |

| 4 | 100 | 114.3 | 105 | 105 |

| 5 | 125 | 141.3 | 124 | 124 |

| 6 | 150 | 168.3 | 143 | 143 |

| 8 | 200 | 219.1 | 178 | 178 |

| 10 | 250 | 273.0 | 216 | 216 |

| 12 | 300 | 323.8 | 254 | 254 |

| 14 | 350 | 355.6 | 279 | 279 |

| 16 | 400 | 406.4 | 305 | 305 |

| 18 | 450 | 457 | 343 | 343 |

| 20 | 500 | 508 | 381 | 381 |

| 22 | 550 | 559 | 419 | 419 |

| 24 | 600 | 610 | 432 | 432 |

| 26 | 650 | 660 | 495 | 495 |

| 28 | 700 | 711 | 521 | 521 |

| 30 | 750 | 762 | 559 | 559 |

| 32 | 800 | 813 | 597 | 597 |

| 34 | 850 | 864 | 635 | 635 |

| 36 | 900 | 914 | 673 | 673 |

| 38 | 950 | 965 | 711 | 711 |

| 40 | 1000 | 1016 | 749 | 749 |

| 42 | 1050 | 1067 | 762 | 711 |

| 44 | 1100 | 1118 | 813 | 762 |

| 46 | 1150 | 1168 | 851 | 800 |

| 48 | 1200 | 1219 | 889 | 838 |

Dimensional Tolerances of Buttweld Equal Cross as per ASME B16.9

| 公称管道尺寸 | 1/2 至2½ | 3 至3½ | 4 | 5 到 8 |

| 外径 在斜角处 (D) |

+ 1.6 – 0.8 |

1.6 | 1.6 | + 2.4 – 1.6 |

| 末端内径 | 0.8 | 1.6 | 1.6 | 1.6 |

| 结束LR的中心 (A/b) | 2 | 2 | 2 | 2 |

| 结束3D的中心 (A/b) | 3 | 3 | 3 | 3 |

| 公称管道尺寸 | 10 到 18 | 20 到 24 | 26 到 30 | 32 到 48 |

| 外径 在斜角处 (D) |

+ 4 – 3.2 |

+ 6.4 – 4.8 |

+ 6.4 – 4.8 |

+ 6.4 – 4.8 |

| 末端内径 | 3.2 | 4.8 | + 6.4 – 4.8 |

+ 6.4 – 4.8 |

| 结束LR的中心 (A/b) | 2 | 2 | 3 | 5 |

| 结束3D的中心 (A/b) | 3 | 3 | 6 | 6 |

| 室壁厚度 (t) | 不少于 87.5% 公称壁厚 | |||

ASME B16.9 Buttweld Equal Cross Weight Chart

| 名义管尺寸 | SCH 10 | SCH 20 | SCH 30 | SCH 40 | ||||||||

| 墙Thk毫米 | 体重公斤 | 体重公斤 | 墙Thk毫米 | 体重公斤 | 体重公斤 | 墙Thk毫米 | 体重公斤 | 体重公斤 | 墙Thk毫米 | 体重公斤 | 体重公斤 | |

| 时间 | 时间 | 时间 | 时间 | |||||||||

| 1/2” | 2.77 | 0.21 | ||||||||||

| 3/4” | 2.87 | 0.21 | ||||||||||

| 1” | 3.38 | 0.34 | ||||||||||

| 1.1/4” | 3.68 | 0.92 | ||||||||||

| 1.1/2” | 3.56 | 0.63 | ||||||||||

| 2” | 3.91 | 1.49 | ||||||||||

| 2.1/2” | 5.16 | 2.68 | ||||||||||

| 3” | 5.49 | 3.75 | ||||||||||

| 3.1/2” | 5.74 | 5 | ||||||||||

| 4” | 6.02 | 6.5 | ||||||||||

| 5” | 6.55 | 10 | ||||||||||

| 6” | 7.11 | 16 | ||||||||||

| 8” | 6.35 | 23 | 7.04 | 24.6 | 8.18 | 27 | ||||||

| 10” | 6.35 | 34.7 | 7.8 | 40 | 9.27 | 41 | ||||||

| 12” | 6.35 | 43.4 | 8.38 | 56.6 | 10.31 | 70.5 | ||||||

| 14” | 6.35 | 68 | 7.92 | 84 | 9.53 | 102 | 11.13 | 105 | ||||

| 16” | 6.35 | 90.8 | 7.92 | 100 | 9.53 | 110 | 12.7 | 167 | ||||

| 18” | 6.35 | 93.1 | 9.53 | 127 | 11.13 | 164 | 14.27 | 237.45 | ||||

| 20” | 6.35 | 112 | 9.53 | 168 | 12.7 | 245 | 15.09 | 320 | ||||

| 22” | 6.35 | 146 | 9.53 | 220 | 12.7 | 280 | ||||||

| 24” | 6.35 | 160 | 12.7 | 240 | 14.27 | 373 | 17.48 | 570.65 | ||||

| 26” | 7.92 | 293.28 | 12.7 | 360.2 | ||||||||

| 28” | 7.92 | 280.98 | 12.7 | 421 | 15.88 | 526.25 | ||||||

| 30” | 7.92 | 322.64 | 12.7 | 483.1 | 15.88 | 603.75 | ||||||

| 32” | 7.92 | 375.23 | 12.7 | 559 | 15.88 | 698.75 | 17.48 | 768.6 | ||||

| 34” | 7.92 | 482.72 | 12.7 | 644.1 | 15.88 | 805.13 | 17.48 | 885.65 | ||||

| 36” | 7.92 | 488.3 | 12.7 | 730.3 | 15.88 | 912.88 | 19.05 | |||||

ASME B16.9 SS Equal Cross Angularity Tolerance

| 最大偏角 | 最大离机距离 | |

| 问 | 磷 | |

| 1/2 A 4 | 1 | 2 |

| 5 A 8 | 2 | 4 |

| 10 A 12 | 3 | 5 |

| 14 A 16 | 3 | 7 |

| 18 A 24 | 4 | 10 |

| 26 A 30 | 5 | 10 |

| 32 A 42 | 5 | 13 |

| 44 A 48 | 5 | 20 |

Buttweld Equal Cross Manufacturing Standards

| ASME标准 | ASME/ANSI B16.9, ASME/ANSI B16.28, MSS-SP-43 |

| DIN标准 | DIN28011, DIN2617, DIN2616, DIN2615, DIN2605 |

| 标准 | EN10253-2, EN10253-1 |

| ASME B16.25 | 对焊端头 |

| ASME B16.9 | 工厂制造的锻制管件对焊 |

| ASME B16.28 | Wrought Steel Equal Cross and Buttwelding Returns |

| ASTM A403 – ASME SA403 | 锻造奥氏体不锈钢管道配件标准规范 |

| MSS SP-43 | 锻 & 低压装配式对焊管件, 耐腐蚀应用 |

Buttweld Equal Cross Materials and Grades

| Stainless Steel Buttweld Equal Cross |

| ASTM A403 WP 组. 304, 304L, 304H, 310, 316, 316L, 316H, 316的, 317L, 321, 347, 904L |

| Carbon Steel Buttweld Equal Cross |

| ASTM A234 WPB, 工作带宽, 世界物理研究所 70, 世界物理研究所 65, 世界物理研究所 60, 世界物理研究所 52, 世界物理研究所 46, & 世界物理研究所 42. |

| Low Temperature Buttweld Equal Cross |

| ASTM A420 WPL6, ASTM A420 WPL3 |

| Alloy Steel Buttweld Equal Cross |

| 美国材料试验协会 / ASME有限公司 234 组. WP1, WP5, WP9, WP11, WP12, WP22, WP91 |

| 复式 & Super Duplex Steel Buttweld Equal Cross |

| ASTM A815, ASME SA815 UNS 编号 S31803, UNS 编号 S32205, 美国S32750, UNS S32950. 材料编号. 1.4462 |

| Nickel Alloy Buttweld Equal Cross |

| 我们 10276 (哈氏合金C 276), 我们 6625 (铬镍铁合金 625), 我们 6601 (铬镍铁合金 601), 我们 6600 (铬镍铁合金 600), 我们 8825 (铬镍铁合金 825), 我们 8020 (合金 20 / 20 CB 3), 我们 4400 (蒙乃尔合金 400), 我们 2201 (镍 201), 美国材料试验协会 / 美国机械工程师学会SB 336 我们 2200 (镍 200) |

Types of Equal Cross

| Equal Cross | ASME B16.9 Equal Cross |

| Equal Cross Pipe Fittings | ASME B16.28 Cross |

| Threaded Equal Cross | MSS-SP-43 Equal Cross |

| Seamless Cross | JIS B2313 Equal Cross |

| Buttweld Welded Equal Cross | JIS B2312 Cross |

| Buttweld Pipe Cross | Fabricated Pipe Cross |

| Forged Equal Cross | Seamless Equal Cross Fittings |

Buttweld Equal Cross Application

ASME B16.9 Equal Cross are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a broad range of Buttweld Pipe Cross through a worldwide network of stock-keeping branches. These Equal Pipe Cross is use in various industries like :

- Stainless Steel Buttweld Equal Cross uses in Oil and Gas Pipeline

- Butt weld Equal Cross uses in Chemical Industry

- Alloy Steel Equal Cross uses in Plumbing

- Buttweld Pipe Cross uses in Heating

- Buttweld Equal Cross Fittings uses in Water Supply Systems

- ANSI B16.9 Buttweld Equal Cross uses in Power Plant

- Buttweld Equal Cross Fitting uses in Paper & 纸浆工业

- Equal Cross uses in General Purpose Applications

- Buttweld Cross uses in Fabrication Industry

- Equal Cross uses in Food Processing Industry

- Buttweld Equal Cross uses in Structural Pipe

不锈钢管供应商温州凯信中国

不锈钢管供应商温州凯信中国