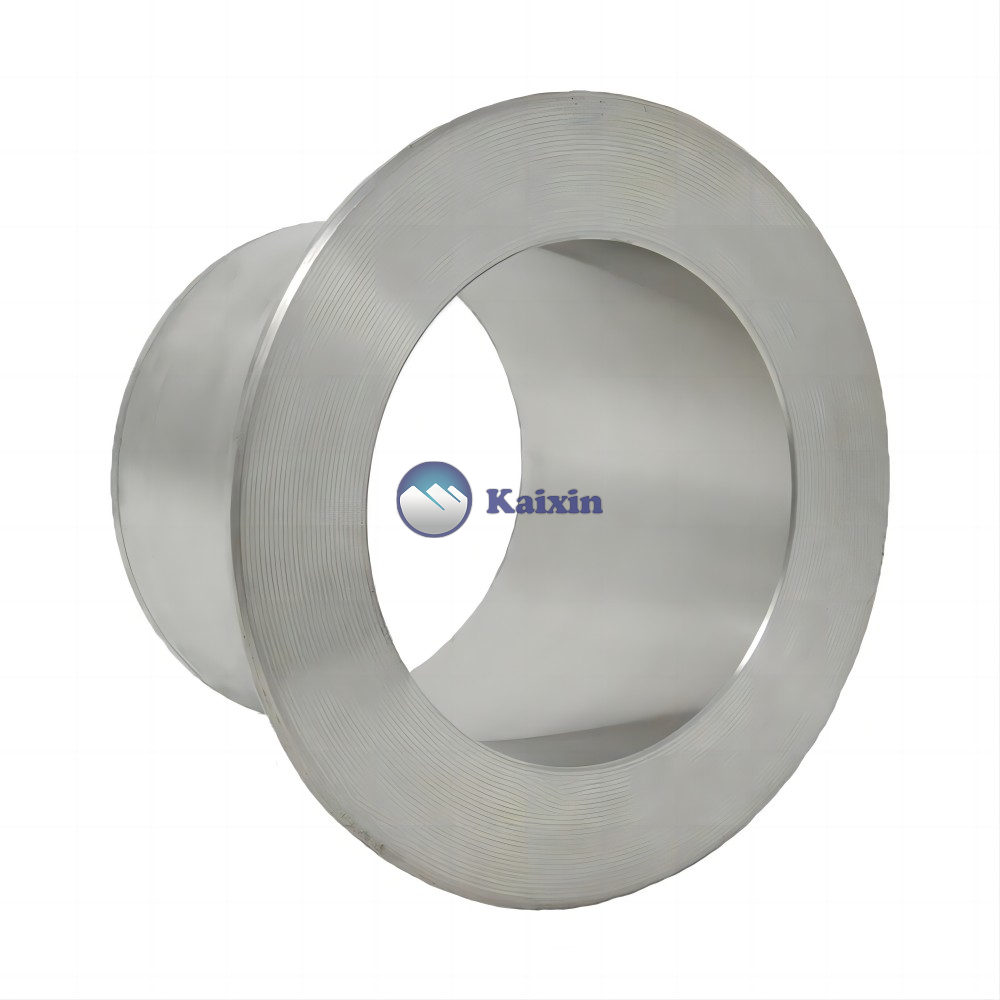

不锈钢短根末端是一种用于管道系统中的管道配件,用于连接两个不同尺寸或材料的管道. 它被设计为短的管道长度,一端形状像法兰,另一端平原, 允许将其焊接到管道或装备. 法兰端用于连接到伴侣法兰, 使卸下关节进行维护或维修变得容易. 不锈钢用于其对腐蚀和高温的极佳耐药性, 使其非常适合在激进的环境中使用. 短根末端通常用于石化, 化学, 和水处理厂, 以及食品和饮料加工设施.

规范 短的 存根结束

| 尺寸 | 1/2“至36”, (无缝至24英寸), (焊接8英寸至36英寸) |

| 标准 | 美标/美国机械工程师协会 :ASTM A403 / ASME SA403, ANSI B16.9, ASME B16.25, ASME B16.28, MSS SP-43.DIN : DIN2605, DIN2615, DIN2616, DIN2617, DIN28011,在 : EN10253-1, EN10253-2 |

| 方面 | ASME/ANSI B16.9, MSS-SP-43 A型, MSS-SP-43 B型, JIS B2312, JIS B2313, ASME B16.28 |

| 厚度 | 附表5S, 10S, 20S, S10, S20, S30, 性病, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS等. |

| 弯曲半径 | R=1D – 10D, 15D, 20D |

| 从 | 短暂的末端, 管头末端, 对接焊缝短管端. |

| 成绩&材料 | ASTM A403 WP316/316L, ASTM A403 SA / A 774 WP-S, WP-W, WP-WX 304/304L, ASTM A182 F316L, 304L, 从 1.4301, DIN1.4306, 从 1.4401, 从 1.4404,美国材料试验协会 815, 美国机械工程师学会 815 UNS 编号 S31803, S32205. 美国S32750, S32950. 材料编号. 1.4462,ASTM A234, ASME SA234 WPB , 工作带宽, 世界物理研究所 42, 世界物理研究所 46, 世界物理研究所 52, WPH 60, 世界物理研究所 65 & WPHY 70.ASTM A420 WPL3, A420 WPL6,美国材料试验协会 / ASME有限公司 234 组. 湿性粉剂 1, 湿性粉剂 5, 湿性粉剂 9, 湿性粉剂 11, 湿性粉剂 12, 湿性粉剂 22, 湿性粉剂 91,ASTM B336, 美国机械工程师协会SB336, 镍 200 (联合国编号. 2200号), 镍 201 (联合国编号. N02201), 蒙乃尔合金 400 (联合国编号. N04400), 蒙乃尔合金 500 (联合国编号. N05500), 铬镍铁合金 800 (联合国编号. N08800), 铬镍铁合金 825 (联合国编号. N08825), 铬镍铁合金 600 (联合国编号. N06600), 铬镍铁合金 625 (联合国编号. N06625), 铬镍铁合金 601 (联合国编号. N06601), 哈氏合金C 276 (联合国编号. N10276), 合金 20 (联合国编号. N08020), 钛 (一级 & 二), 铜镍合金 70/30, 铜镍10铁1锰, 铜镍30锰1铁. |

| 类型 | 无缝的 / 英亩 / 焊接式 / 捏造的 |

| 表面涂料 | 环氧涂层, 黑色涂漆, 清漆, 镀锌。连接 |

| 连接类型 | 结束钟 / 螺纹/夹具端 / 焊接/法兰/ |

短存根端制造标准

| ASME标准 | ASME/ANSI B16.9, ASME/ANSI B16.28, MSS-SP-43 |

| DIN标准 | DIN28011, DIN2617, DIN2616, DIN2615, DIN2605 |

| 标准 | EN10253-2, EN10253-1 |

| ASME B16.25 | 对焊端头 |

| ASME B16.9 | 工厂制造的锻制管件对焊 |

| ASME B16.28 | 锻钢偏心异径管 |

| ASTM A403 – ASME SA403 | 锻制奥氏体不锈钢管道配件标准规范 |

| MSS SP-43 | 锻 & 低压装配式对焊管件, 耐腐蚀应用 |

简短的存根末端材料和等级

| 不锈钢臀部焊缝长枪 | ASTM A403 WP316/316L, ASTM A403 SA / A 774 WP-S, WP-W, WP-WX 304/304L, ASTM A182 F316L, 304L, 从 1.4301, DIN1.4306, 从 1.4401, 从 1.4404 |

| 复式 & 超级双工钢臀部韦尔德长短端 | 美国材料试验协会 815, 美国机械工程师学会 815 UNS 编号 S31803, S32205. 美国S32750, S32950. 材料编号. 1.4462 |

| 碳钢臀部焊缝长枪 | ASTM A234, ASME SA234 WPB , 工作带宽, 世界物理研究所 42, 世界物理研究所 46, 世界物理研究所 52, WPH 60, 世界物理研究所 65 & 世界物理研究所 70. |

| 低温碳钢臀部韦尔德长枪端 | ASTM A420 WPL3, A420 WPL6 |

| 合金钢臀部韦尔德长轴 | 美国材料试验协会 / ASME有限公司 234 组. 湿性粉剂 1, 湿性粉剂 5, 湿性粉剂 9, 湿性粉剂 11, 湿性粉剂 12, 湿性粉剂 22, 湿性粉剂 91 |

| 镍合金臀部长枪 | ASTM B336, 美国机械工程师协会SB336, 镍 200 (联合国编号. 2200号), 镍 201 (联合国编号. N02201), 蒙乃尔合金 400 (联合国编号. N04400), 蒙乃尔合金 500 (联合国编号. N05500), 铬镍铁合金 800 (联合国编号. N08800), 铬镍铁合金 825 (联合国编号. N08825), 铬镍铁合金 600 (联合国编号. N06600), 铬镍铁合金 625 (联合国编号. N06625), 铬镍铁合金 601 (联合国编号. N06601), 哈氏合金C 276 (联合国编号. N10276), 合金 20 (联合国编号. N08020), 钛 (一级 & 二), 铜镍合金 70/30, 铜镍10铁1锰, 铜镍30锰1铁. |

短存根端类型

Short Stub End are offered in three different ways, 类型A。, b和c. A型和B存根端类似于锻造配件, 例如肘部和T恤, 和C型存根端以定制大小制作.

类型A。

The Type A Short Stub End is employed for standard joint flange. 存根端的膝盖厚度大于或直至管墙的标称厚度. 此外, a的外角半径将接收长的法兰. 内角是正方形. 圈有时包括加工的粗糙脸.

类型b

The Type B Short Stub End is employed for standard slip on flanges as lap flanges. 这些短末端的膝盖厚度大于或直至管墙的标称厚度. 还, B型的外角半径足够小,可以接收将用作备用法兰的滑动o法兰. 内角是正方形. Short Stub End sometimes includes a machined rough face.

类型c

The Type C Short Stub End will be used for standard Long flange, 并放在法兰. 这是张开的壮丽壮举. 如有必要, 半径将被创建为正方形. 膝盖厚度是管壁的第75. c非常短,足以容纳任何备用法兰. The Short Stub End on kind C is smooth, and it’s not machined.The lap thickness is 75th of the pipe wall. c非常短,足以容纳任何备用法兰. 长的固执末端很光滑, 而且不是加工的.

短存根末端尺寸

| 产品 | 名义. 管道尺寸 | 直径 (G) | 长度 (J) | 外径 (O.D.) | Schedule 10S Approx. 重量 | Schedule 10S, 内径 (ID。) | Schedule 10S, 室壁厚度 (时间) | Schedule 5S Approx. 重量 | 附表5S, 内径 (ID。) | 附表5S, 室壁厚度 (时间) |

| 1 1/2″ Lap- 关节存根端 / 存根末端短类型 “C” | 1.5 | 2.875 | 2 | 1.9 | 0.44 | 1.682 | 0.109 | 0.29 | 1.77 | 0.065 |

| 1 1/4″ Lap- 关节存根端 / 存根末端短类型 “C” | 1.25 | 2.5 | 2 | 1.66 | 0.42 | 1.442 | 0.109 | 0.21 | 1.53 | 0.065 |

| 1″ Lap- 关节存根端 / 存根末端短类型 “C” | 1 | 2 | 2 | 1.315 | 0.31 | 1.097 | 0.109 | 0.19 | 1.185 | 0.065 |

| 1/2″ Lap- 关节存根端 / 存根末端短类型 “C” | 0.5 | 1.375 | 2 | 0.84 | 0.14 | 0.674 | 0.083 | 0.13 | 0.71 | 0.065 |

| 10″ Lap- 关节存根端 / 存根末端短类型 “C” | 10 | 12.75 | 5 | 10.75 | 9.46 | 1042 | 0.165 | 7.48 | 10.482 | 0.134 |

| 12″ Lap- 关节存根端 / 存根末端短类型 “C” | 12 | 15 | 6 | 12.75 | 16.07 | 12.39 | 0.18 | 15 | 12.438 | 0.156 |

| 14″ Lap- 关节存根端 / 存根末端短类型 “C” | 14 | 16.25 | 6 | 14 | 23.1 | 13.624 | 0.188 | 19.2 | 13.688 | 0.156 |

| 16″ Lap- 关节存根端 / 存根末端短类型 “C” | 16 | 18.5 | 6 | 16 | 27.2 | 15.624 | 0.188 | 23.9 | 15.67 | 0.165 |

| 18″ Lap- 关节存根端 / 存根末端短类型 “C” | 18 | 21 | 6 | 18 | 32.4 | 17.624 | 0.188 | 28.5 | 17.67 | 0.165 |

| 2 1/2″ Lap- 关节存根端 / 存根末端短类型 “C” | 2.5 | 4.125 | 2.5 | 2.875 | 1 | 2.635 | 0.12 | 0.75 | 2.709 | 0.083 |

| 2″ Lap- 关节存根端 / 存根末端短类型 “C” | 2 | 3.625 | 2.5 | 2.375 | 0.81 | 2.157 | 0.109 | 0.44 | 2.245 | 0.065 |

| 20″ Lap- 关节存根端 / 存根末端短类型 “C” | 20 | 23 | 6 | 20 | 47.7 | 19.564 | 0.218 | 36.3 | 19.624 | 0.188 |

| 24″ Lap- 关节存根端 / 存根末端短类型 “C” | 24 | 27.25 | 6 | 24 | 58.27 | 23.5 | 0.25 | 56 | 23.564 | 0.218 |

| 3″ Lap- 关节存根端 / 存根末端短类型 “C” | 3 | 5 | 2.5 | 3.5 | 1.25 | 3.26 | 0.12 | 0.94 | 3.334 | 0.083 |

| 3/4″ Lap- 关节存根端 / 存根末端短类型 “C” | 0.75 | 1.688 | 2 | 1.05 | 0.18 | 0.884 | 0.083 | 0.14 | 0.92 | 0.065 |

| 4″ Lap- 关节存根端 / 存根末端短类型 “C” | 4 | 6.188 | 3 | 4.5 | 1.88 | 4.26 | 0.12 | 1.38 | 4.334 | 0.083 |

| 5″ Lap- 关节存根端 / 存根末端短类型 “C” | 5 | 7.313 | 3 | 5.563 | 2.63 | 5.295 | 0.134 | 2.06 | 5.345 | 0.109 |

| 6″ Lap- 关节存根端 / 存根末端短类型 “C” | 6 | 8.5 | 3.5 | 6.625 | 3.56 | 6.357 | 0.134 | 2.75 | 6.407 | 0.109 |

| 8″ Lap- 关节存根端 / 存根末端短类型 “C” | 8 | 10.625 | 4 | 8.625 | 6.19 | 8.329 | 0.148 | 3.88 | 8.407 | 0.109 |

| 存根末端 - ANSI B 16.9 和MSS SP-43维度 | |||||||

| 英寸 | ND | 毫米 | 膝盖直径 | 圆角半径 | 长度f | ||

| D | G | 右 | R1 | MSS SP43 | ANSI B16.9 | ||

| 1/2 | 15 | 21,34 | 34,92 | 3,17 | 0,80 | 50,80 | 76,20 |

| 3/4 | 20 | 26,67 | 42,86 | 3,17 | 0,80 | 50,80 | 76,20 |

| 1 | 25 | 33,40 | 50,80 | 3,17 | 0,80 | 50,80 | 101,60 |

| 1 1/4 | 32 | 42,16 | 63,50 | 4,76 | 0,80 | 50,80 | 101,60 |

| 1 1/2 | 40 | 48,26 | 73,00 | 6,35 | 0,80 | 50,80 | 101,60 |

| 2 | 50 | 60,32 | 92,10 | 7,93 | 0,80 | 63,50 | 152,40 |

| 2 1/2 | 65 | 73,02 | 104,80 | 7,93 | 0,80 | 63,50 | 152,40 |

| 3 | 80 | 88,90 | 127,00 | 9,52 | 0,80 | 63,50 | 152,40 |

| 3 1/2 | 90 | 101,60 | 139,70 | 9,52 | 0,80 | 76,20 | 152,40 |

| 4 | 100 | 114,30 | 157,20 | 11,11 | 0,80 | 76,20 | 152,40 |

| 5 | 125 | 141,30 | 185,70 | 11,11 | 1,58 | 76,20 | 203,20 |

| 6 | 150 | 168,27 | 215,90 | 12,70 | 1,58 | 88,90 | 203,20 |

| 8 | 200 | 219,07 | 269,80 | 12,70 | 1,58 | 101,60 | 203,20 |

| 10 | 250 | 273,05 | 323,80 | 12,70 | 1,58 | 127,00 | 254,00 |

| 12 | 300 | 323,85 | 381,00 | 12,70 | 1,58 | 152,40 | 254,00 |

| 14 | 350 | 355,60 | 412,70 | 12,70 | 1,58 | 152,40 | 304,80 |

| 16 | 400 | 406,40 | 469,90 | 12,70 | 1,58 | 152,40 | 304,80 |

| 18 | 450 | 457,20 | 533,40 | 12,70 | 1,58 | 152,40 | 304,80 |

| 20 | 500 | 508,00 | 584,20 | 12,70 | 1,58 | 152,40 | 304,80 |

| 22 | 550 | 558,80 | 641,30 | 12,70 | 1,58 | 152,40 | 304,80 |

| 24 | 600 | 609,60 | 692,10 | 12,70 | 1,58 | 152,40 | 304,80 |

| 膝盖厚度T不得小于标称管道壁厚 | |||||||

短暂的末端长度

| 标称 | 日程 | D | t | G | F | 右. 最大限度. | 千克 / 英石. | |

| 1/2 “ | 10s | 21.3 | 2.11 | 34.9 | 50.8 | 3.18 | 0.07 | s |

| 40s | 2.77 | 0.09 | s | |||||

| 3/4 “ | 10s | 26.7 | 2.11 | 42.9 | 50.8 | 3.18 | 0.10 | s |

| 40s | 2.87 | 0.12 | s | |||||

| 1 “ | 10s | 33.4 | 2.77 | 50.8 | 50.8 | 3.18 | 0.16 | s / w |

| 40s | 3.38 | 0.17 | s | |||||

| 1 1/4 “ | 10s | 42.2 | 2.77 | 63.5 | 50.8 | 4.76 | 0.22 | s |

| 40s | 3.56 | 0.25 | s | |||||

| 1 1/2 “ | 10s | 48.3 | 2.77 | 73.0 | 50.8 | 6.35 | 0.25 | s / w |

| 40s | 3.68 | 0.31 | s | |||||

| 2 “ | 10s | 60.3 | 2.77 | 92.1 | 63.5 | 7.94 | 0.43 | s / w |

| 40s | 3.91 | 0.61 | s | |||||

| 2 1/2 “ | 10s | 73.0 | 3.05 | 104.8 | 63.5 | 7.94 | 0.57 | s / w |

| 40s | 5.16 | 0.80 | s | |||||

| 3 “ | 10s | 88.9 | 3.05 | 127.0 | 63.5 | 9.53 | 0.73 | s / w |

| 40s | 5.49 | 1.13 | s | |||||

| 4 “ | 10s | 114.3 | 3.05 | 157.2 | 76.2 | 11.11 | 1.09 | s / w |

| 40s | 6.02 | 1.87 | s | |||||

| 5 “ | 10s | 141.3 | 3.40 | 185.7 | 76.2 | 11.11 | 1.47 | s / w |

| 40s | 6.55 | 2.28 | s | |||||

| 6 “ | 10s | 168.3 | 3.40 | 215.9 | 88.9 | 12.70 | 2.15 | s / w |

| 40s | 7.11 | 3.57 | s / w | |||||

| 8 “ | 10s | 219.1 | 3.76 | 269.9 | 101.6 | 12.70 | 3.22 | s / w |

| 40s | 8.18 | 6.07 | s / w | |||||

| 10 “ | 10s | 273.1 | 4.19 | 323.9 | 127.0 | 12.70 | 5.13 | w |

| 40s | 9.27 | 10.07 | w | |||||

| 12 “ | 10s | 323.9 | 4.57 | 381.0 | 152.4 | 12.70 | 8.16 | w |

| 40s | 9.53 | 14.29 | w | |||||

| 14 “ | 10s | 355.6 | 4.78 | 412.8 | 152.4 | 12.70 | 10.89 | w |

| 40s | 9.53 | 17.15 | w | |||||

| 16 “ | 10s | 406.4 | 4.78 | 469.9 | 152.4 | 12.70 | 12.70 | w |

| 40s | 9.53 | 20.41 | w | |||||

| 18 “ | 10s | 457.2 | 4.78 | 533.4 | 152.4 | 12.70 | 17.24 | w |

| 20 “ | 10s | 508.0 | 5.54 | 584.2 | 152.4 | 12.70 | 21.77 | w |

| 24 “ | 10s | 609.6 | 6.35 | 692.2 | 152.4 | 12.70 | 27.22 | w |

短存根端尺寸耐受性

MSS SP-43仅覆盖不锈钢对接焊缝焊缝长枪末端配件,该配件适用于附表5和10s长的存根端,适用于附表40s管道, 如ASME B36.19中的概述. MSS SP-43区域单位中概述的规模和尺寸公差与NPS中的ASME B16.9规格相似。 1/2 - NP二十四. 除了与斜角处的皮肤直径有关.

| 长短的末端 | ||

| 外径. lap g | 膝盖的圆角半径 - r | 总长度. – F |

| +0 -1 | +0-1 | 2 |

| +0 -1 | +0-1 | 2 |

| +0 -1 | +0 -2 | 2 |

| +0-1 | +0 -2 | 2 |

| +0 -1 | +0 -2 | 2 |

| +0 -2 | +0 -2 | 2 |

| +0 -2 | +0-2 | 3 |

| +0 -2 | +0 -2 | 3 |

短存根端重量图

| 核动力源 英寸 |

存根末端 | |||

| 施. 5S |

施. 10S |

施. 40S |

施. 80S |

|

| 1/2 | 0.06 | 0.08 | 0.12 | 0.13 |

| 3/4 | 0.07 | 0.09 | 0.15 | 0.17 |

| 1 | 0.09 | 0.15 | 0.20 | 0.25 |

| 1 1/4 | 0.13 | 0.20 | 0.30 | 0.35 |

| 1 1/2 | 0.16 | 0.25 | 0.38 | 0.46 |

| 2 | 0.25 | 0.40 | 0.55 | 0.75 |

| 2 1/2 | 0.35 | 0.50 | 0.80 | 1.00 |

| 3 | 0.50 | 0.60 | 1.10 | 1.50 |

| 4 | 0.70 | 1.00 | 1.80 | 2.50 |

| 5 | 1.00 | 1.25 | 2.50 | 3.50 |

| 6 | 1.60 | 1.95 | 3.70 | 5.50 |

| 8 | 2.50 | 3.10 | 5.90 | 10.0 |

| 10 | 4.00 | 4.90 | 10.5 | 14.0 |

| 12 | 6.60 | 7.10 | 15.0 | 20.0 |

| 14 | 6.40 | 7.80 | 15.5 | 20.5 |

| 16 | 7.90 | 9.00 | 18.0 | 24.0 |

| 18 | 9.30 | 10.5 | 21.0 | 28.0 |

| 20 | 12.0 | 13.5 | 23.5 | 31.0 |

| 24 | 16.5 | 19.0 | 28.5 | 38.0 |

| 大约重量(公斤), 密度 8 公斤/分立方米 | ||||

短的 存根末端的角度公差

| ND | 最大偏角 | 最大离机距离 |

| 问 | 磷 | |

| 1/2 A 4 | 1 | 2 |

| 5 A 8 | 2 | 4 |

| 10 A 12 | 3 | 5 |

| 14 A 16 | 3 | 7 |

| 18 A 24 | 4 | 10 |

| 26 A 30 | 5 | 10 |

| 32 A 42 | 5 | 13 |

| 44 A 48 | 5 | 20 |

ASME B16.9 BUTTWELD短暂终端可用类型

| Buttweld短暂终点 | 对接焊缝短管端 |

| ASME B16.9 Butt weld Short Stub End | Steel Short Stub Ends Fittings |

| Stainless Steel Short Stub End Suppliers | SS Buttweld Short Stub Ends Fitting |

| ANSI B16.9 Buttweld Short Stub End Dealer | ASME B16.28 Buttweld Short Stub Ends Exporter |

| Welded Butt weld Short Stub Ends Stockholder | Seamless Butt weld Short Stub End Distributors |

| Carbon Steel Short Stub End | High Quality Short Stub End Manufacturer |

| ASTM A403 Stainless Steel Short Stub Ends | Duplex Steel Buttweld Short Stub End |

| Super Duplex Steel Buttweld Short Stub End | Copper Nickel Short Stub End |

| High Nickel Alloy Short Stub Ends | Hastelloy Short Stub Ends Stockist |

| Titanium Buttweld Short Stub End | Inconel Butt weld Short Stub End |

短存根端申请

- Stainless Steel Buttweld Short Stub End uses in Oil and Gas Pipeline

- Butt weld Short Stub Ends uses in Chemical Industry

- Alloy Steel Short Stub Ends uses in Plumbing

- Buttweld Short Stub Ends uses in Heating

- Buttweld Short Stub End Fittings uses in Water Supply Systems

- ANSI B16.9 Buttweld Short Stub Ends uses in Power Plant

- Buttweld Short Stub End Fitting uses in Paper & 纸浆工业

- Short Stub End uses in General Purpose Applications

- Buttweld Short Stub End uses in Fabrication Industry

- Short Stub End uses in Food Processing Industry

- Buttweld Short Stub Ends uses in Structural Pipe

不锈钢管供应商温州凯信中国

不锈钢管供应商温州凯信中国