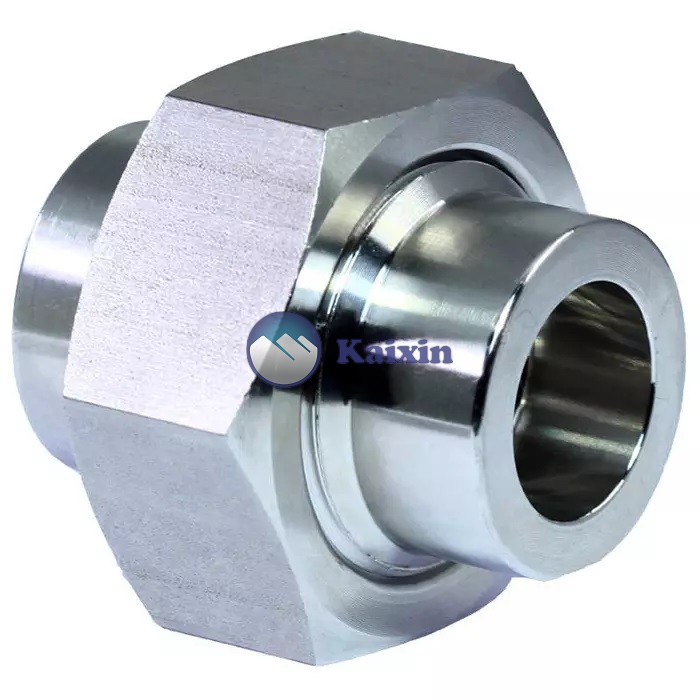

What is A 承插焊 Union?

Socket Weld Unions are available within the male & female types, lug nut, and Rockwood design. Union suits the MSS SP 83 standard. Socket Weld Unions are almost like couplings, they’re generally easier to require apart and permit pipes of various metals to return together safely. Stainless steel Socket Weld Unions are utilized in low piping where it’s required to dismantle the pipe often. A Forged Socket Weld Union may be a joint design. It consists of three interconnected pieces. This Union Pipe Fittings has two internal threads, and a centerpiece that pulls the ends together when rotated.

Typically socket weld union carbon steel pipe parts are locked together with the help of a radical screw or the nut with the sized cross-sections of it. In cases where there could be a sever pulling stress taking into the ASME B16.11 Socket Weld Union pipe from outside, the locking screw can break off. Also the locking screw can remove the other two parts of the union, which in turn will then separate the pipe to which it has been attached.

A socket weld union is a type of pipe fitting that is used to connect two pipes together in a way that allows for easy disassembly. The union has a threaded sleeve that is attached to one end of each of the two pipes, while the other end of the sleeve is attached to a central hub with a socket weld connection. This allows the two pipes to be easily connected and disconnected without the need for tools or special equipment, making it ideal for applications where frequent maintenance is required. The socket weld union is commonly used in high-pressure piping systems, where it is important to maintain a tight and secure seal between the connected pipes.

Socket Weld Union Specifications

| 尺寸 | 1/8″NB TO 4″NB |

| 标准 | ASME/ANSI B16.11, MSS SP-79, MSS-SP-95, 83, 97,DIN28011, DIN2617, DIN2616, DIN2615, DIN2605,EN10253-2, EN10253-1 |

| 方面 | 美国机械工程师协会 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, 学士 3799 |

| 厚度 | 附表5S, 10S, 20S, S10, S20, S30, 性病, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS等. |

| 压力等级 | 2000位置服务,3000 位置服务, 6000 位置服务, 9000 位置服务 |

| 从 | Socket Weld union, Socket Weld End union, Socket Weld Pipe union |

| 成绩&材料 | 美国材料试验协会 / ASME有限公司 182 – F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316的, 316H, 316L, 316闪电网络, 317, 317L, 321, 321H, 347, 347H, 904美国ASTM / ASME有限公司 182 – F44, F45, F51, F53, F55, F60, F61.ASTM / 美国机械工程师学会SB 564 / 160 / 472 - 我们 2200 (镍 200), 我们 4400 (蒙乃尔合金 400), 我们 8825 铬镍铁合金 (825), 我们 6600(铬镍铁合金 600), 我们 6601 (铬镍铁合金 601), 我们 6625 (铬镍铁合金 625), 我们 10276 (哈氏合金C 276), 我们 2201 (镍 201), (合金 20 / 20 CB 3),美国材料试验协会 / 美国机械工程师学会SB 61 / 62 / 151 / 152 – 有些不. C 92200, 有些不. C 83600, 有些不. 70600, 71500, C 70600 (与-NI- 90/10), C 71500 (与-NI- 70/30), UNS NO C 10100, C 10200, C 10300, C 10800, C 12000, C 12200,ASTMA 105/A694/A350 LF3/A350 LF2 – F42, F46, F52, F56、F60, F65, F70, ASTM A182 – F1, F5, F9, F11, F22, F91,黄铜CA 360, CA 345 和CA 377 / SAE J530, SAE J531 和 ASA |

| 类型 | 承插焊 (西南) & 拧紧 (SCRD) – 不扩散条约, 中央银行, BSPT |

Manufacturing Standards of Socket Weld Union

| ASME标准 | ASME/ANSI B16.11, MSS SP-79, MSS-SP-95, 83, 97 |

| DIN标准 | DIN28011, DIN2617, DIN2616, DIN2615, DIN2605 |

| 标准 | EN10253-2, EN10253-1 |

| ASME B16.11 | 承插焊管件, 承插 - 焊接和螺纹 |

| ASTM A182 – ASME SA182 | 锻造奥氏体不锈钢管道承插焊管件的标准规范 |

| MSS SP-95 | 型锻(d) 乳头和牛塞 |

美国机械工程师协会 / ANSI B16.11 Socket Weld Union 材料 & 成绩

| 不锈钢承插焊管接头 |

| ASTM A403 WP 组. 304, 304L, 304H, 310, 316, 316L, 316H, 316的, 317L, 321, 347, 904L |

| Carbon Steel Socket Weld Union |

| ASTM A234 WPB, 工作带宽, 世界物理研究所 70, 世界物理研究所 65, 世界物理研究所 60, 世界物理研究所 52, 世界物理研究所 46, & 世界物理研究所 42. |

| Low Temperature Socket Weld Union |

| ASTM A420 WPL6, ASTM A420 WPL3 |

| Alloy Steel Socket Weld Union |

| 美国材料试验协会 / ASME有限公司 234 组. WP1, WP5, WP9, WP11, WP12, WP22, WP91 |

| 复式 & Super Duplex Steel Socket Weld Union |

| ASTM A815, ASME SA815 UNS 编号 S31803, UNS 编号 S32205, 美国S32750, UNS S32950. 材料编号. 1.4462 |

| Nickel Alloy Socket Weld Union |

| 我们 10276 (哈氏合金C 276), 我们 6625 (铬镍铁合金 625), 我们 6601 (铬镍铁合金 601), 我们 6600 (铬镍铁合金 600), 我们 8825 (铬镍铁合金 825), 我们 8020 (合金 20 / 20 CB 3), 我们 4400 (蒙乃尔合金 400), 我们 2201 (镍 201), 美国材料试验协会 / 美国机械工程师学会SB 336 我们 2200 (镍 200) |

High Pressure Socket Weld Union Types by Size, 班级, 和壁厚

| 描述 | 类别名称 | ||

| 2000 | 3000 | 6000 | |

| Unions | 1/2 – 4 | 1/2 – 2 | 1/2 – 2 |

| 1/2 – 4 | 1/2 – 2 | 1/2 – 2 | |

| 1/2 – 4 | 1/2 – 2 | 1/2 – 2 | |

| 管道尺寸

按壁厚 |

SCH 80 / XS | SCH 160 | XXS |

Dimensions of ASME B16.11 Socket Weld Union

Socket Weld Union Dimension Drawing

| 公称直径 | 外径 |

室壁厚度 |

Socket Bore |

Water way Bore |

Depth of Socket |

长度组装 标称 |

|||

| Dmin | Cmin | d1 | d2 | Jmin | L | ||||

| DN | 核动力源 | 插座 | 螺纹式 | 插座 | 螺纹式 | 插座 | 插座 & 螺纹式 |

插座 | 插座 & 螺纹式 |

| 6 | 1/8 | 21.8 | 14.7 | 3.2 | 2.5 | 10.65 | 6.43 | 10 | 41.4 |

| 8 | 1/4 | 21.8 | 19.0 | 3.3 | 3.1 | 14.10 | 9.45 | 10 | 41.4 |

| 10 | 3/8 | 25.9 | 22.9 | 3.5 | 3.2 | 17.55 | 13.51 | 10 | 46.0 |

| 15 | 1/2 | 31.2 | 27.7 | 4.1 | 3.8 | 21.70 | 17.07 | 10 | 49.0 |

| 20 | 3/4 | 37.1 | 33.5 | 4.3 | 4.0 | 27.05 | 21.39 | 13 | 56.9 |

| 25 | 1 | 45.5 | 41.4 | 5.0 | 4.6 | 33.80 | 27.74 | 13 | 62.0 |

| 32 | 11/4 | 54.9 | 50.5 | 5.3 | 4.9 | 42.55 | 35.36 | 13 | 71.1 |

| 40 | 11/2 | 61.5 | 57.2 | 5.6 | 5.1 | 48.65 | 41.20 | 13 | 76.5 |

| 50 | 2 | 75.2 | 70.1 | 6.1 | 5.6 | 61.10 | 52.12 | 16 | 86.1 |

| 65 | 21/2 | 91.7 | 85.3 | 7.7 | 7.1 | 73.80 | 64.31 | 16 | 102.4 |

| 80 | 3 | 109.2 | 102.4 | 8.4 | 7.7 | 89.80 | 77.27 | 16 | 109.0 |

ASME B16.11 Socket Weld Union Fittings Dimensions Tolerance

| Socket Weld Union ASME B16.11 Tolerance (Union) | Union | |||

| 承插焊管件尺寸 (核动力源) | 外部 直径 在斜角处 |

里面 直径 结束时 |

壁厚T | 中心到末端 方面 A ,C ,乙 |

| 1/2 到 2-1/2 | +0.06 | 不少于 87.5% 标称厚度 |

+/- 0.06 | |

| -0.03 | ||||

| 3 到 3-1/2 | +/- 0.06 | +/- 0.06 | +/- 0.06 | |

| 4 | +/- 0.06 | +/- 0.06 | +/- 0.06 | |

| 5 到 8 | +/- 0.06 | +/- 0.06 | +/- 0.06 | |

| 10 到 18 | +0.16 | +/- 0.12 | +/- 0.09 | |

| -0.12 | ||||

| 20 到 24 | +0.25 | +/- 0.19 | +/- 0.09 | |

| -0.19 | ||||

| 26 到 30 | +0.25 | +/- 0.19 | +/- 0.12 | |

| -0.19 | ||||

| 32 到 48 | +0.25 | +/- 0.19 | +/- 0.19 | |

| -0.19 | ||||

Socket Weld Union Weight

Socket Weld Union Weight

| CLASS 3000 Socket Weld Union | ||||||||||||

| PIPE SIZE | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 |

| A | 1.375 | 1.375 | 1.625 | 1.813 | 2.250 | 2.562 | 3.063 | 3.438 | 4.063 | 4.875 | 5.688 | 6.875 |

| 乙 | 1.688 | 1.688 | 1.813 | 1.938 | 2.250 | 2.438 | 2.813 | 3.000 | 3.375 | 4.031 | 4.313 | 8.000 |

| C | 0.865 | 0.865 | 1.025 | 1.235 | 1.465 | 1.795 | 2.165 | 2.425 | 2.965 | 3.615 | 4.305 | 5.415 |

| D | 0.426 | 0.560 | 0.693 | 0.859 | 1.071 | 1.335 | 1.682 | 1.922 | 2.410 | 2.910 | 3.536 | 4.545 |

| 乙 | 0.813 | 0.813 | 0.938 | 0.938 | 1.125 | 1.188 | 1.438 | 1.500 | 1.625 | 2.250 | 2.313 | 5.000 |

| 位置服务 | 0.40 | 0.38 | 0.52 | 0.73 | 1.19 | 1.66 | 2.66 | 3.42 | 5.36 | 9.12 | 12.58 | 17.50 |

| CLASS 6000 Socket Weld Union | ||||||||||||

| PIPE SIZE | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 |

| A | 1.375 | 1.625 | 1.813 | 2.250 | 2.562 | 3.063 | 3.438 | 4.063 | 4.875 | 5.688 | 6.875 | — |

| 乙 | 1.688 | 1.813 | 1.938 | 2.250 | 2.438 | 2.813 | 3.000 | 3.375 | 4.031 | 4.313 | 8.000 | — |

| C | 0.865 | 1.025 | 1.235 | 1.465 | 1.795 | 2.165 | 2.425 | 2.965 | 3.615 | 4.305 | 5.415 | — |

| D | 0.426 | 0.560 | 0.693 | 0.859 | 1.071 | 1.335 | 1.682 | 1.922 | 2.410 | 2.910 | 3.536 | — |

| 乙 | 0.813 | 0.813 | 0.938 | 0.938 | 1.125 | 1.188 | 1.438 | 1.500 | 1.625 | 2.250 | 5.750 | — |

| 位置服务 | 0.48 | 0.56 | 0.75 | 1.35 | 2.01 | 3.17 | 3.92 | 6.60 | 10.12 | 14.00 | 40.891 | — |

| CLASS 9000 Socket Weld Union | ||||||||||||

| PIPE SIZE | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 |

| A | 1.750 | 2.000 | 2.250 | 2.563 | 3.063 | 3.688 | 4.313 | 5.000 | 5.750 | 6.875 | — | — |

| 乙 | 2.500 | 2.563 | 2.938 | 3.250 | 3.750 | 4.000 | 4.625 | 4.813 | 5.563 | 6.25 | — | — |

| C | 1.000 | 1.250 | 1.500 | 1.750 | 2.250 | 2.500 | 3.000 | 3.625 | 4.250 | 5.000 | — | — |

| D | 0.426 | 0.560 | 0.693 | 0.859 | 1.071 | 1.335 | 1.682 | 1.922 | 2.410 | 2.910 | — | — |

| 乙 | 1.720 | 1.688 | 1.938 | 2.000 | 2.375 | 2.375 | 3.000 | 2.938 | 3.188 | 3.750 | — | — |

| 位置服务 | 0.89 | 1.045 | 1.955 | 3.29 | 5.34 | 7.99 | 12.73 | 18.34 | 26.36 | 37.07 | — | — |

ASME B16.11 SS Socket Weld Union Angularity Tolerance

| ND | 最大偏角 | 最大离机距离 |

| 问 | 磷 | |

| 1/2 A 4 | 1 | 2 |

| 5 A 8 | 2 | 4 |

| 10 A 12 | 3 | 5 |

| 14 A 16 | 3 | 7 |

| 18 A 24 | 4 | 10 |

| 26 A 30 | 5 | 10 |

| 32 A 42 | 5 | 13 |

| 44 A 48 | 5 | 20 |

ASME B16.11 Forged Socket Weld Union Available Types

| Forged Socket weld Union | Socket weld Union |

| 150 磅. Socket Weld Fittings Union | Socket weld Forged Union |

| ASME B16.11 Forged Socket weld Union | Forged Unions 3000LB Socket Weld |

| Stainless Steel Union Suppliers | SS Forged Socket weld Union |

| ANSI B16.11 Forged Socket weld Union Dealer | 学士 3799 Forged Unions Exporter |

| Forged Socket weld Union Stockholder | Socket weld Forged Union Distributors |

| Carbon Steel Socket weld Union | High Quality Socket weld Union Manufacturer |

| ASTM A182 Socket weld Stainless Steel Union | Duplex Steel Socket weld Union |

| Super Duplex Steel End Unions | Copper Nickel Socket weld Union |

| High Nickel Alloy Forged Socket weld Union | Hastelloy Socket weld Union Stockist |

| Titanium Forged Socket weld Union | Inconel Socket weld Unions |

Socket Weld Union Application

- Stainless Steel Forged Socket weld Union uses in Oil and Gas Pipeline

- Forged Socket weld Union uses in Chemical Industry

- Alloy Steel Socket weld Union uses in Plumbing

- Forged Socket weld End Unions uses in Heating

- Socket weld Forged Unions uses in Water Supply Systems

- ANSI B16.11 Forged Socket weld Union uses in Power Plant

- Socket weld Union uses in Paper & 纸浆工业

- Forged Socket weld Unions uses in General Purpose Applications

- Forged Socket weld Union uses in Fabrication Industry

- Forged Socket weld Union uses in Food Processing Industry

- Forged Socket weld Unions uses in Structural Pipe

不锈钢管供应商温州凯信中国

不锈钢管供应商温州凯信中国